PCB automatic processing system

A processing system and heating device technology, applied in rotary printing presses, printing, printing presses, etc., can solve the problems that high-quality patch cannot be completed reliably, the rise and fall of the squeegee is difficult to control, and the overall structural stability is insufficient, and the overall structure can be achieved. Reasonable, reliable and efficient, simple structure, stable adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

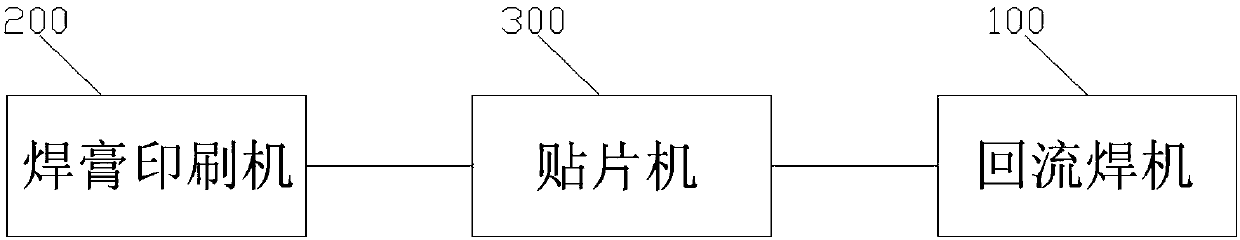

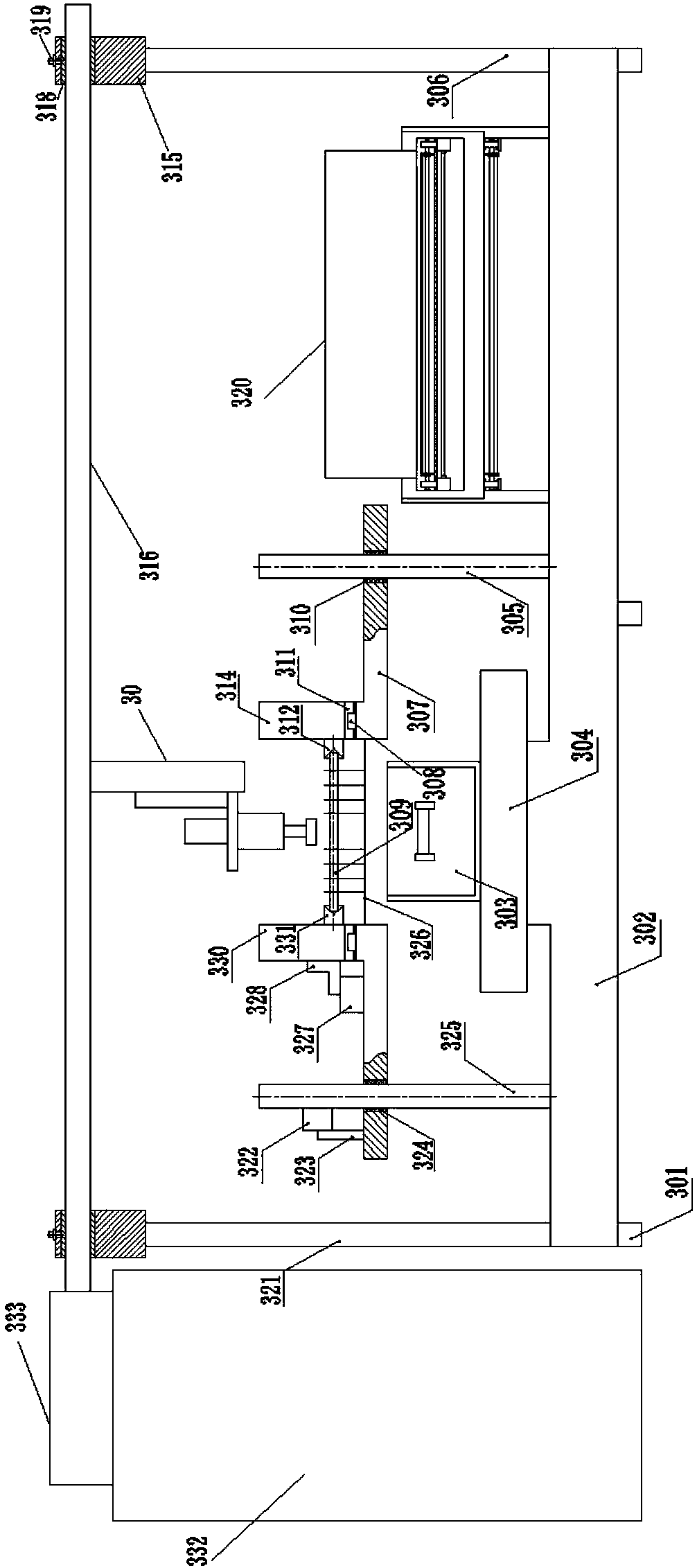

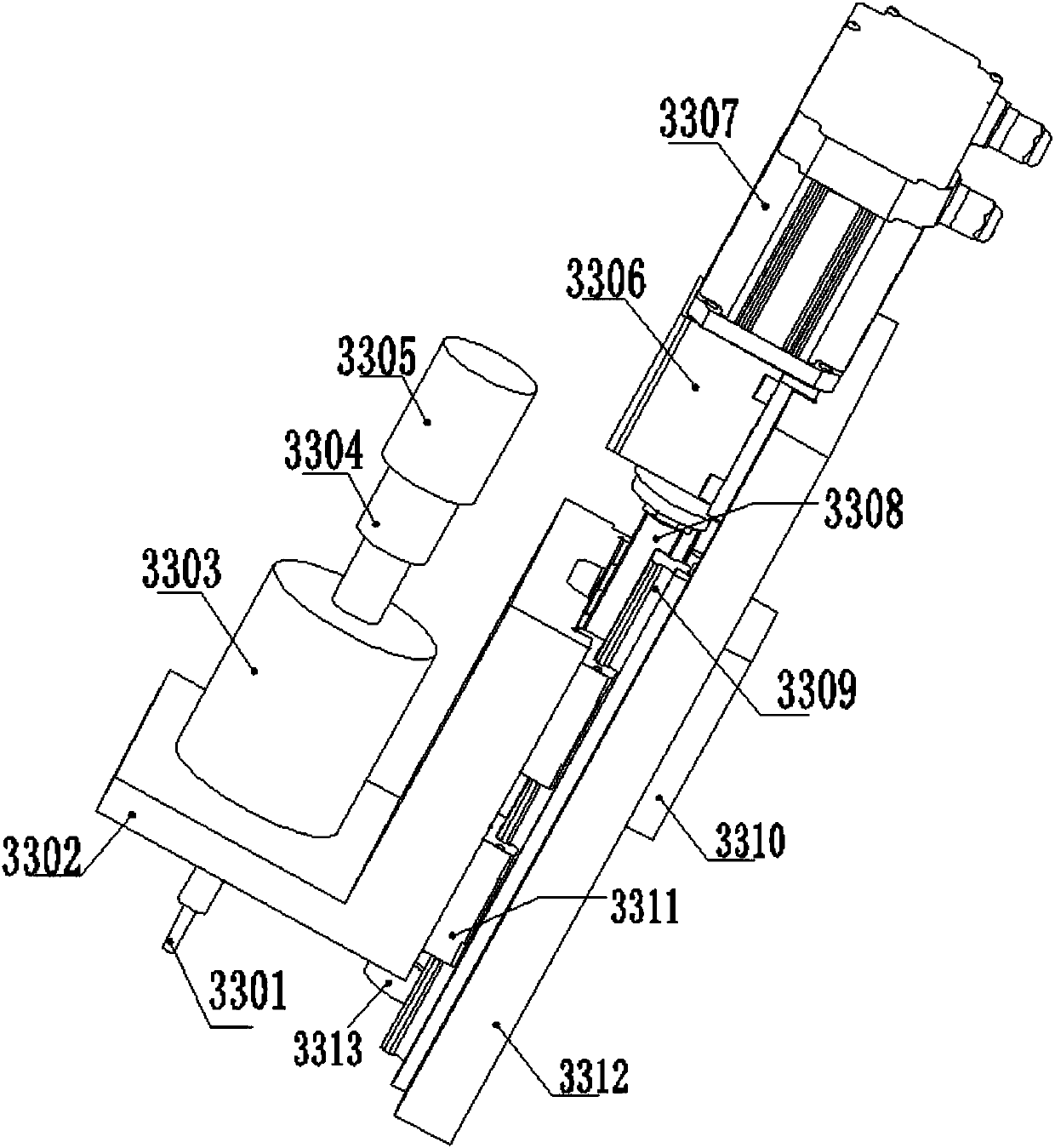

[0040] Such as Figure 1-16 As shown, it shows a specific embodiment of the present invention, a PCB automatic processing system of the present invention, including a solder paste printing machine, a placement machine and a reflow soldering machine arranged in sequence;

[0041] The solder paste printing machine includes a printing frame, the printing frame is fixedly installed, a slide plate is installed on the printing frame, a scraper translation device is installed on the slide plate, the entire scraper lifting device is installed on the scraper frame, and two solder paste machines are installed vertically downward on the top of the scraper frame Cylinder, the cylinder ejector rod of the solder paste machine cylinder is connected to the light rod connector. Install two light rods symmetrically, the light rods extend vertically downwards, and pass through the bottom of the printing frame, the lower end of the light rods is equipped with a scraper, the two scrapers are insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com