Air inflation type deodorization double-layer heating type cold and hot optional tea rolling equipment

A double-layer heating and processing equipment technology, which is applied in tea treatment before extraction, can solve the problems of affecting the rolling effect, affecting the quality, and long rolling time, so as to achieve rapid automatic pressure-adjustable rolling and reduce the dull yellow taste of tea leaves , Fast heating and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

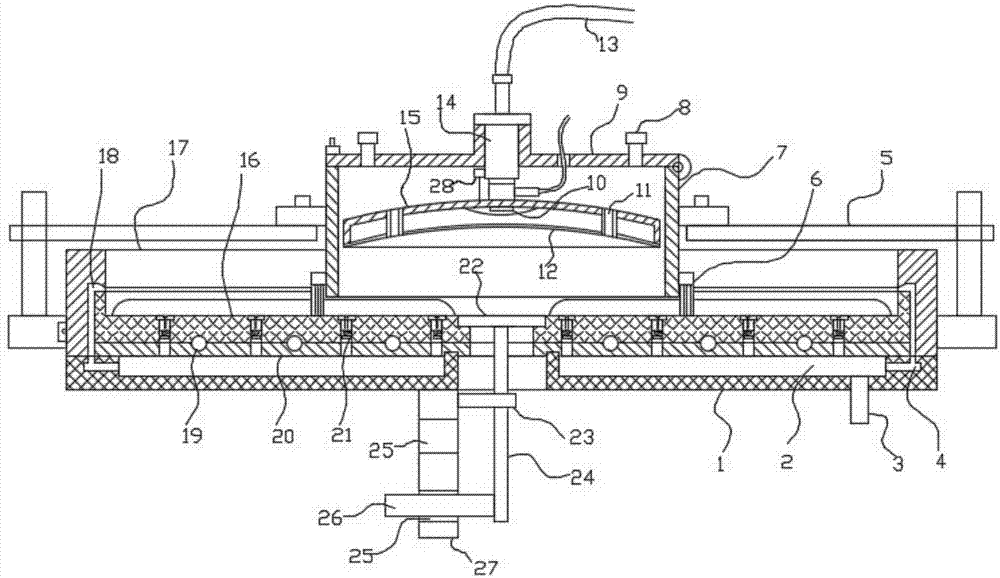

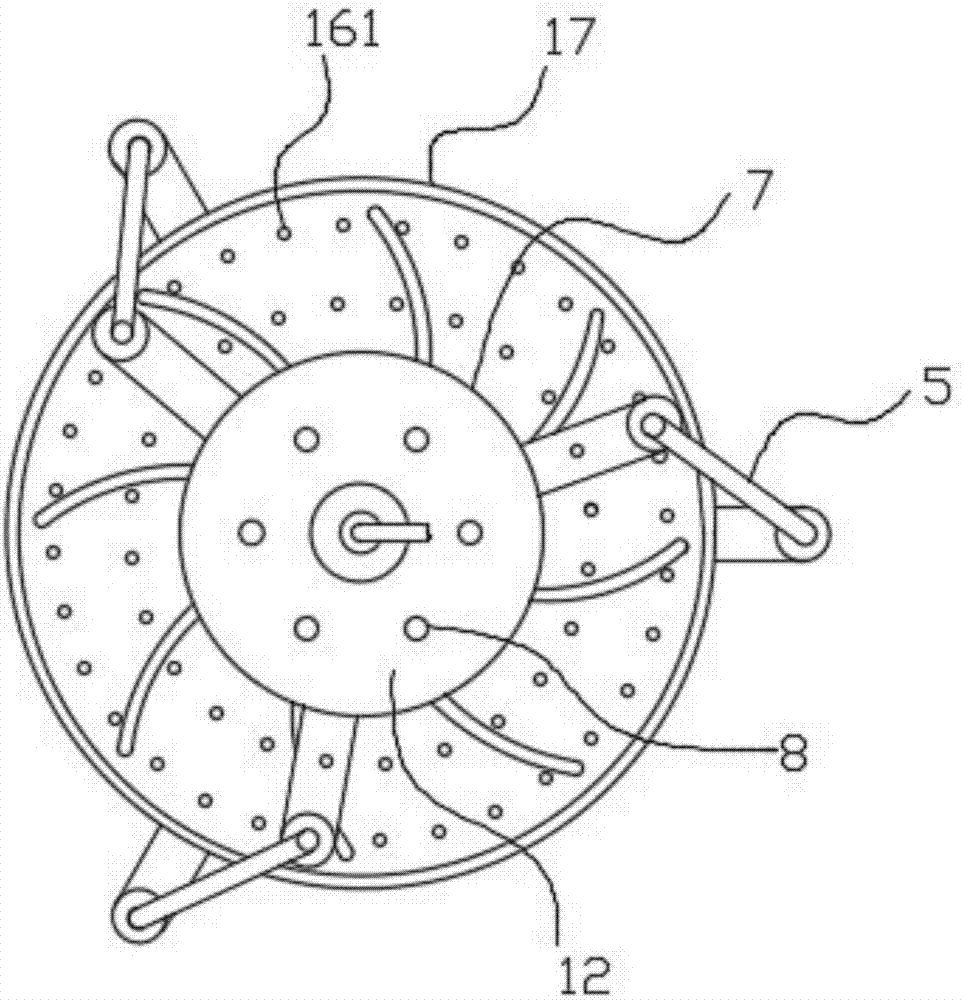

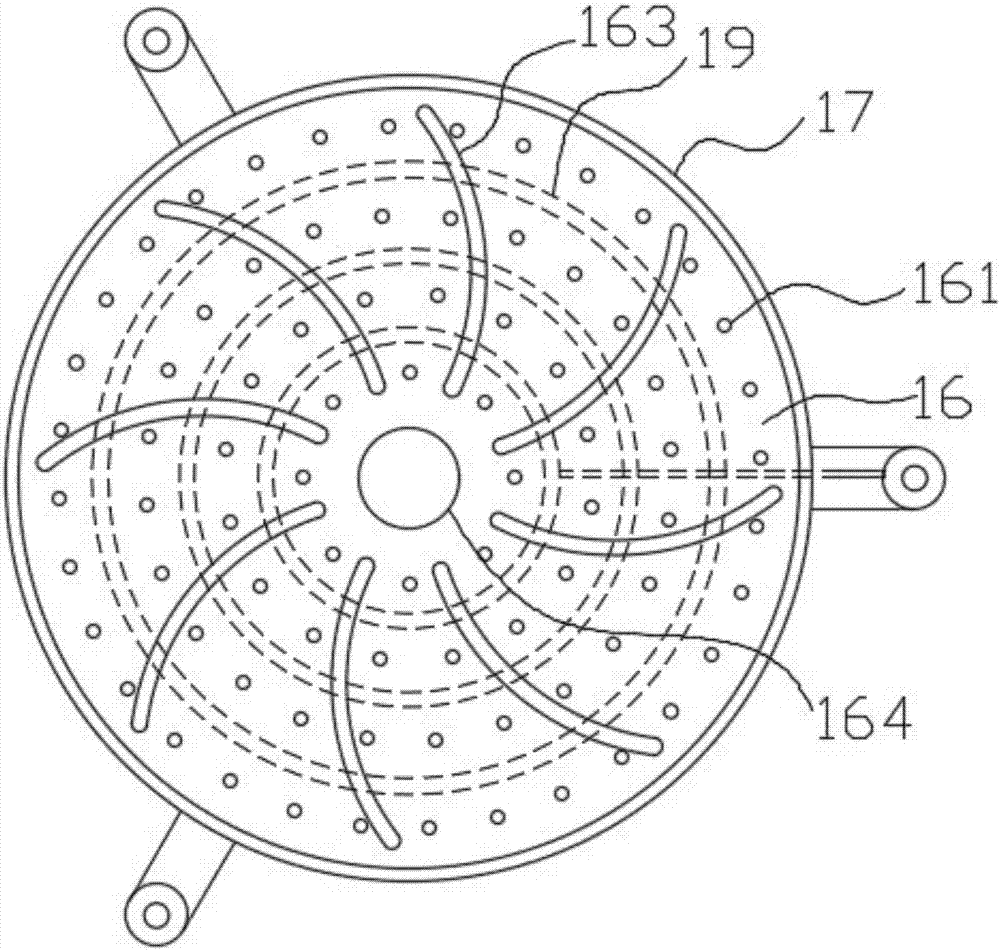

[0035] Such as Figure 1-Figure 8As shown, the specific structure of the present invention is: a kind of steaming type deodorizing double-layer heating type tea kneading processing equipment with optional hot and cold, which includes the kneading cylinder 7 arranged on the kneading disc 16, which is in the shape of The annular array is provided with arc-shaped kneading protrusions 163; the kneading cylinder 7 is evenly hinged with a transmission rod 5 on the periphery; the transmission rod 5 is connected to a drive motor; the kneading disc 16 is evenly provided with air holes 161; The lower end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com