Dotted bonding type auxetic yarn processing device and processing method

A processing device and bonding technology, applied in the direction of yarn, adhesive, spinning machine, etc., can solve the problems of unstable yarn structure, limited yarn types, and single yarn types, etc., and achieve obvious auxetic effect, The effect of short spinning process and simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

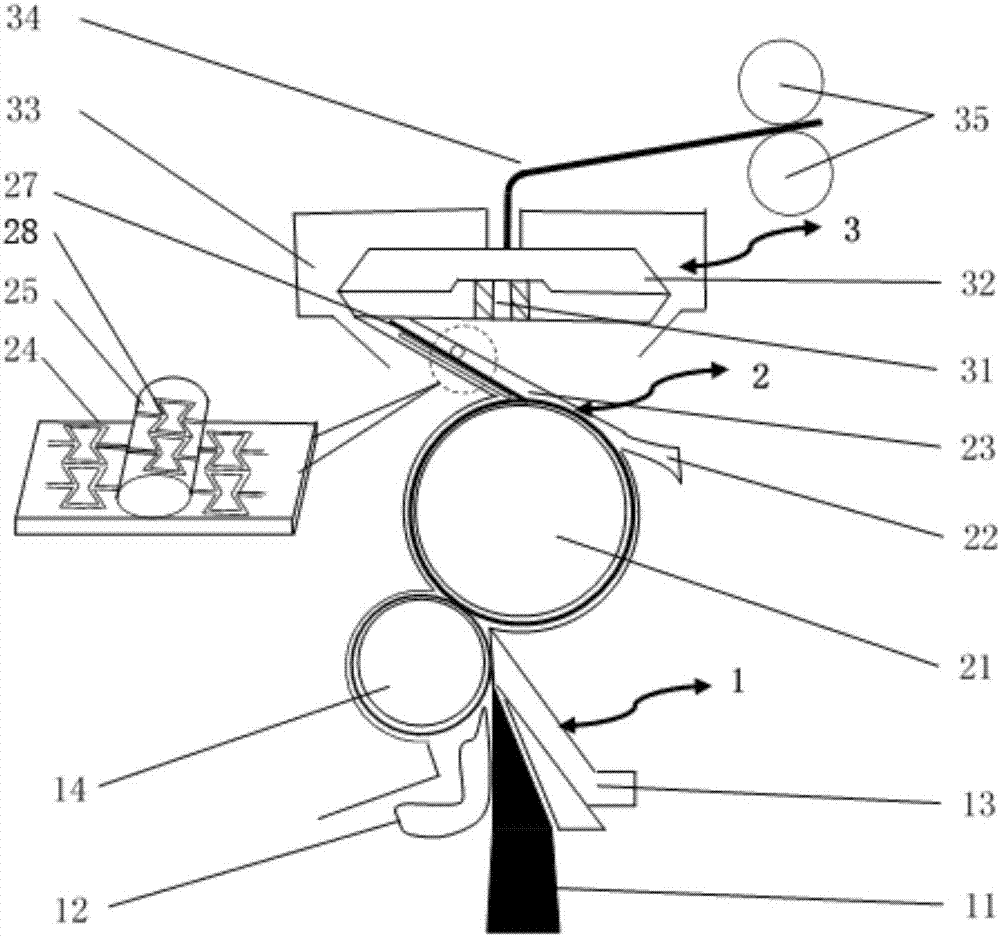

[0052] Example 1 Preparation of Concave Hexagonal Negative Poisson's Ratio Viscose Fiber Yarn

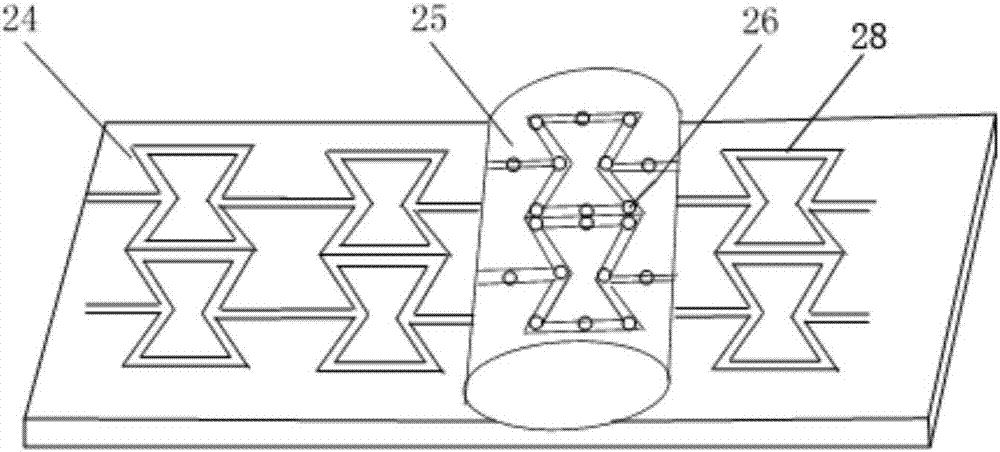

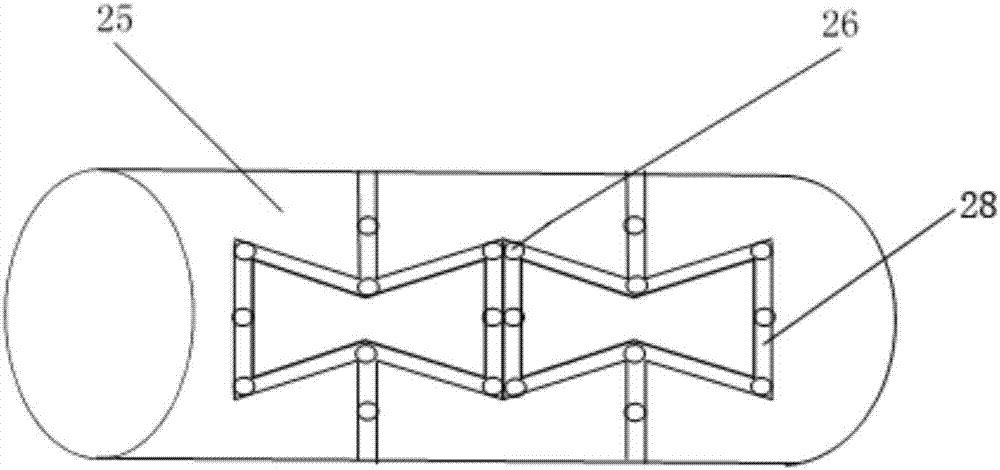

[0053] The unit geometry of the shaping template 24 and the negative Poisson’s ratio geometric shaping groove 28 on the surface of the roller 25 is a concave hexagon, such as Image 6 Shown.

[0054] The viscose staple fiber roving is selected as the raw material, and the viscose staple fiber roving is fed to the horn 12 and the feeding plate 13 to effectively hold and transport to the feeding roller 14; the fed viscose staple fiber roving is then transported to the sub The comb roller 21, after being combed by the carding roller 21, is transported to the plane of the channel formed by the shaping template 24 and the drum 25 through the airflow effect of the conveying channel 23, and forms an auxetic structure under the squeezing action of the shaping template 24 and the drum 25 It is shaped and output synchronously under the shaping action of the light radiation generated by the light r...

Embodiment 2

[0056] Example 2 Preparation of Concave Hexagonal Negative Poisson's Ratio Polyester Fiber Yarn

[0057] The unit geometry of the shaping template 24 and the negative Poisson’s ratio geometric shaping groove 28 on the surface of the roller 25 is a concave hexagon, such as Image 6 Shown.

[0058] Using polyester staple fiber roving as the raw material, the polyester staple fiber roving is fed to the horn 12 and the feeding plate 13 to be effectively held and conveyed to the feeding roller 14; the fed polyester staple fiber roving is then conveyed to the carding roller 21 After being combed by the carding roller 21, it is conveyed to the plane of the channel formed by the shaping template 24 and the drum 25 through the airflow effect of the conveying channel 23. Under the squeezing action of the shaping template 24 and the drum 25, an auxetic structural shape is formed. Under the setting action of the ultrasonic wave generated by the ultrasonic device, it is synchronized and output;...

Embodiment 3

[0060] Example 3 Preparation of Concave Hexagonal Negative Poisson Ratio Viscose-Polyester Blended Fiber Yarn

[0061] The unit geometry of the shaping template 24 and the negative Poisson’s ratio geometric shaping groove 28 on the surface of the roller 25 is a concave hexagon, such as Image 6 Shown.

[0062] The viscose-polyester blended spun roving strand is selected as the raw material, and the viscose-polyester blended spun roving is fed to the horn 12 and the feeding plate 13 to effectively hold and transport to the feeding roller 14; the fed viscose-polyester After the blended short fiber roving is transported to the opening roller 21, after being carded by the opening roller 21, it is transported to the plane of the channel formed by the setting template 24 and the drum 25 through the airflow effect of the conveying channel 23. The swelling structure is formed under the squeezing action of the squeezing device, and it is set and output synchronously under the ultrasonic act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com