Drainage system and method

A drainage system and drainage pipe technology, which is applied in drainage, earthwork drilling, pump control, etc., can solve problems affecting underground production, mine submersion, and large operation randomness, so as to reduce equipment failure rate, reduce running time, reduce The effect of the number of starts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

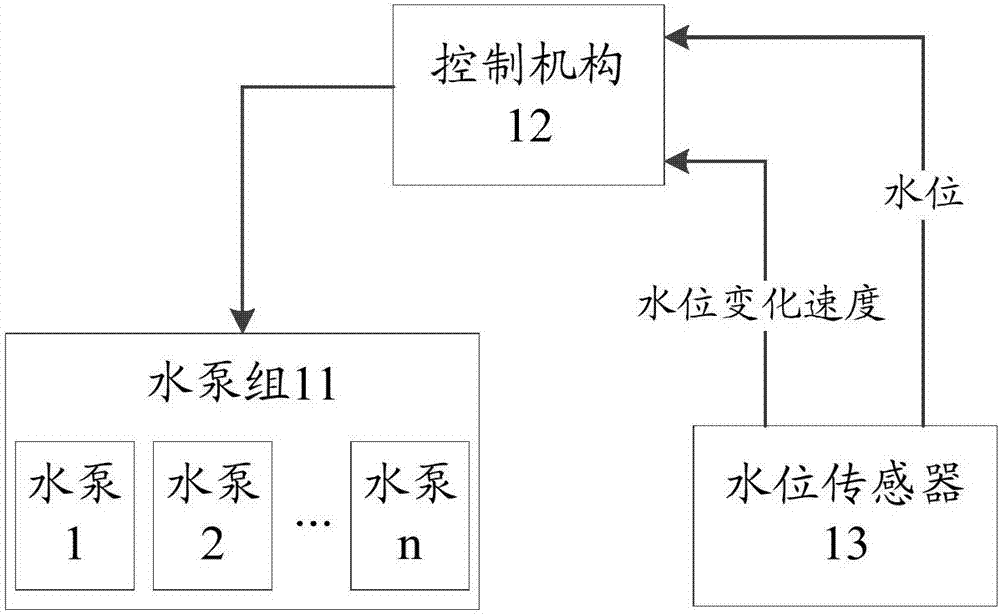

[0050] figure 1 It is a schematic diagram of a drainage system in an embodiment of the present invention, as figure 1 As shown, a drainage system includes a water pump group 11, a control mechanism 12 and a water level sensor 13; wherein,

[0051] The water pump group 11 is used for: draining water according to the instruction of the control mechanism 12, and the water pump group 11 is provided with at least two water pumps, so that it is convenient to alternate between the water pumps and reduce the failure rate of equipment;

[0052] The control mechanism 12 is configured to: when the water level information reaches a preset condition, instruct the water pump group 11 to drain water;

[0053] Here, the water level information includes the water level and the rate of change of the water level. The rate of change of the water level is also referred to as the rate of change of the water level. is a negative value, so that when the water level change rate is large, it means that...

Embodiment 2

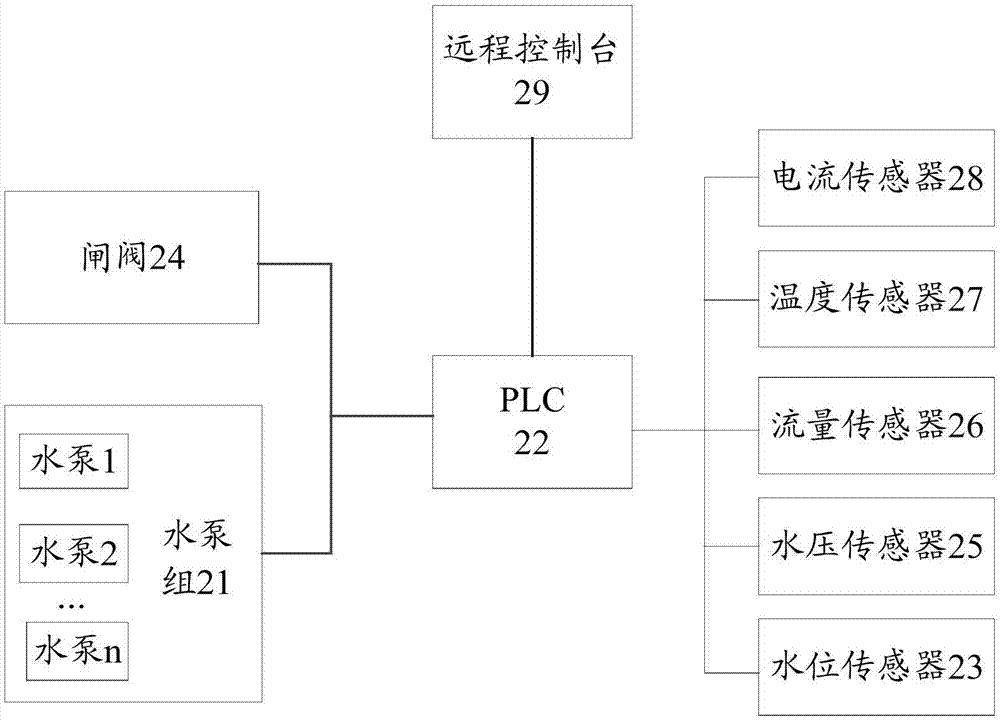

[0057] figure 2 It is a schematic diagram of the second drainage system of the present invention, as figure 2 As shown, a drainage system includes a water pump group 21, PLC22, a water level sensor 23, a gate valve 24, a water pressure sensor 25, a flow sensor 26, a temperature sensor 27, a current sensor 28, a remote console 29 and an on-site operation console; wherein,

[0058] The water pump group 21 is used for: draining water according to the instruction of the PLC22, and the water pump group 21 is provided with at least two water pumps, which facilitates the alternate work between the water pumps and reduces the equipment failure rate;

[0059] The water pumps are all centrifugal pumps, and above the centrifugal pumps are equipped with jet pumps that help the centrifugal pumps to generate negative pressure; specifically, the water pump startup process includes: first start the jet pumps to make the centrifugal pumps generate negative pressure, that is, Vacuum degree, ...

Embodiment 3

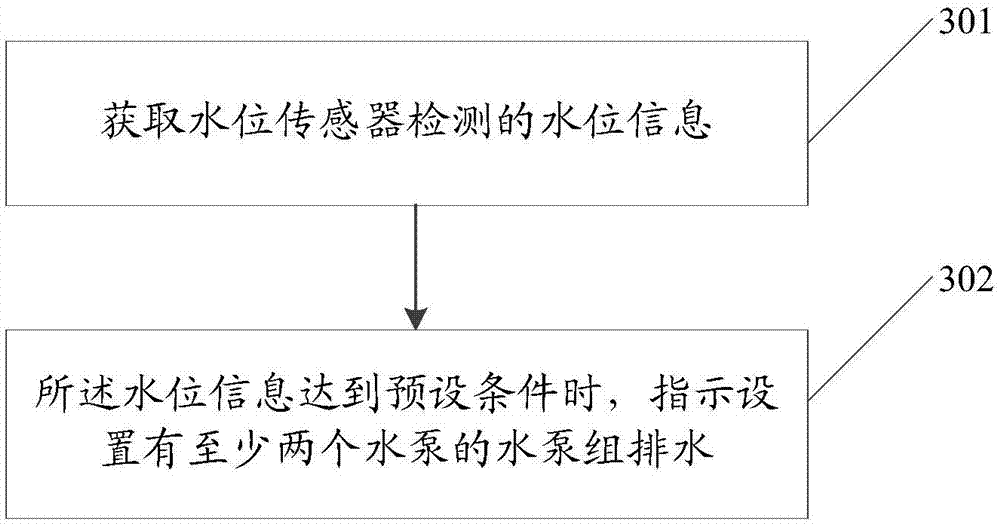

[0098] image 3 It is a schematic diagram of the three drainage methods of the embodiment of the present invention, as image 3 As shown, the method includes:

[0099] Step 301: Obtain the water level information detected by the water level sensor;

[0100] Specifically, the drainage system includes a water pump group, a PLC and a water level sensor, and the PLC obtains water level information through the water level sensor;

[0101] The obtaining of the water level information detected by the water level sensor includes:

[0102] The PLC obtains the water level detected by the water level sensor and the speed of water level change;

[0103] Here, the water level change rate is also called the water level change rate. For the convenience of processing, the water level change rate of the water level increase is defined as a positive value, and the water level change rate of the water level decrease is defined as a negative value. In this way, when the water level change rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com