A two-stage adjustable valve lift device for an engine

A valve lift and adjustable technology, which is applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of grooved ejector pin damage, poor stability, low-speed cam and high-speed cam cannot be switched freely, and improve stability Good performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

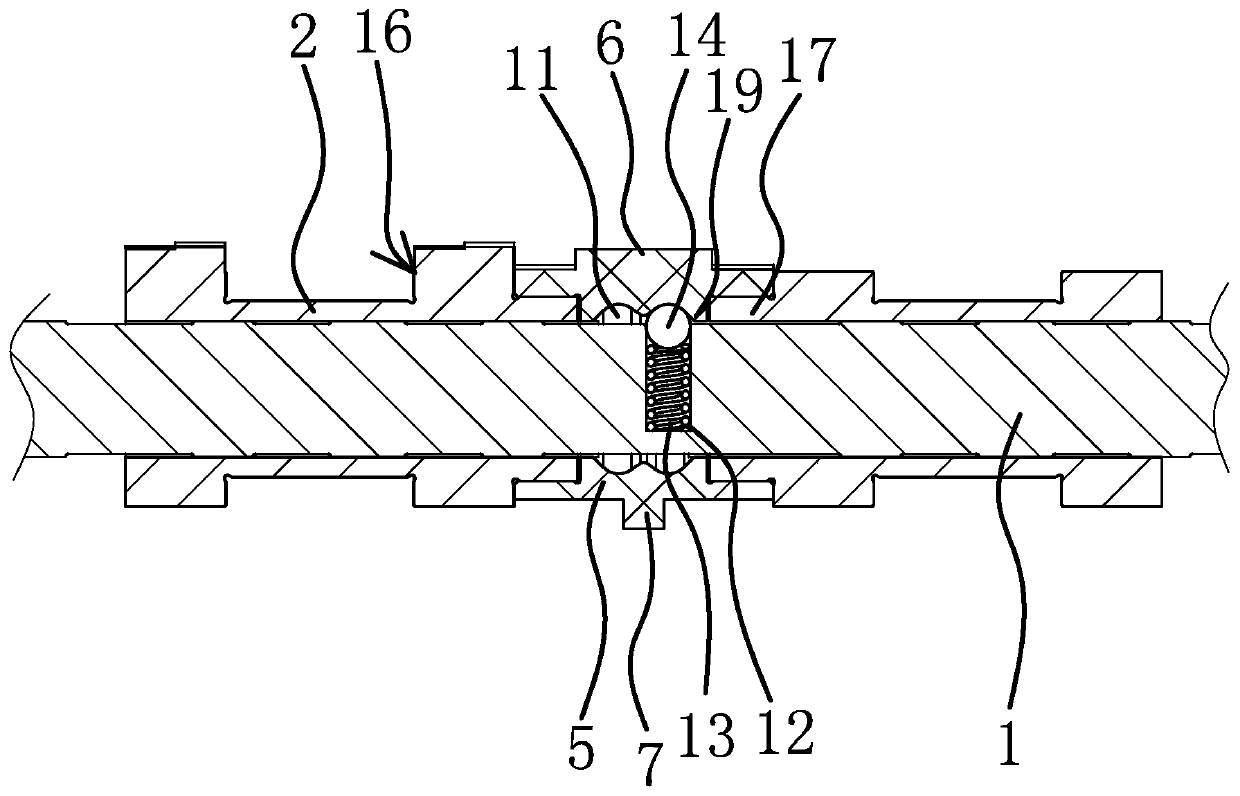

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

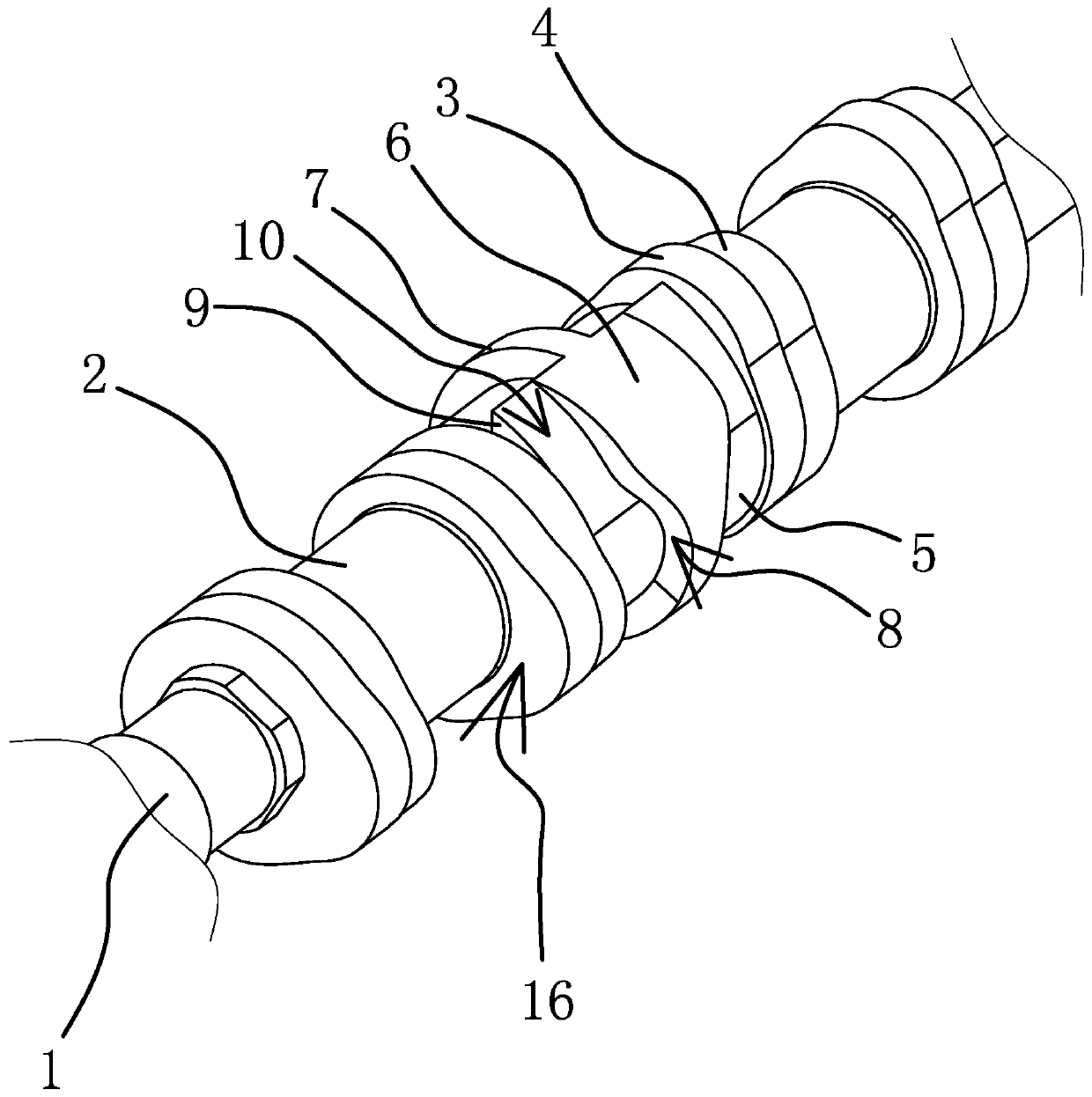

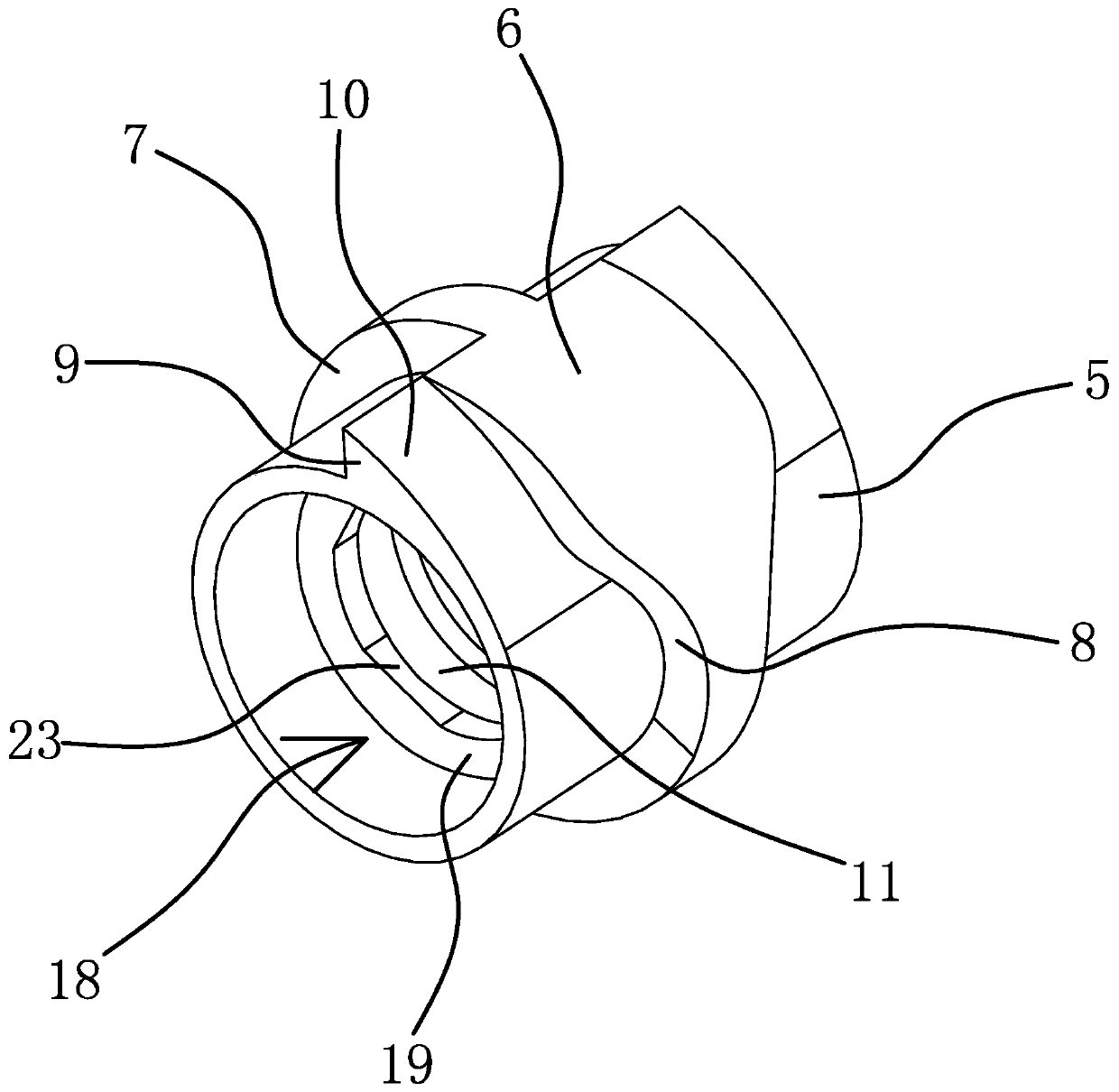

[0027] Such as figure 1 , figure 2 As shown, the two-stage adjustable valve lift device of the engine includes a camshaft 1, a camshaft sleeve 2, a high-speed cam 3, a low-speed cam 4 and an adjustment sleeve 5.

[0028]The outer wall of the camshaft 1 has a protruding abutment ring 20. In this embodiment, the outer wall of the abutment ring 20 has four cut surfaces 21, and the inner wall of the camshaft sleeve 2 is provided with four first The planes 22 , the cutting planes 21 and the first planes 22 are set in one-to-one correspondence. In actual production, the number of the cutting planes 21 can be three or six, and the number of the first planes 22 can also be three or six. The camshaft sleeve 2 is circumferentiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com