A set of large diameter rocket thrust chamber with discharging regenerative cooling partition plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

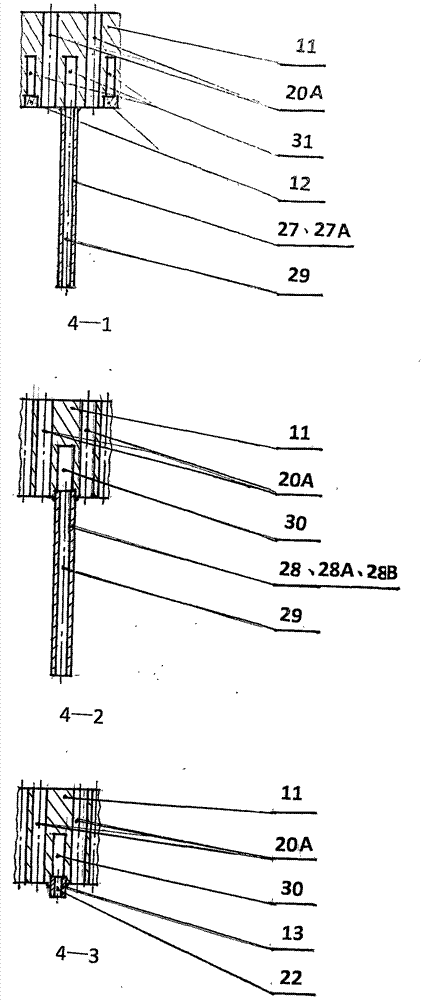

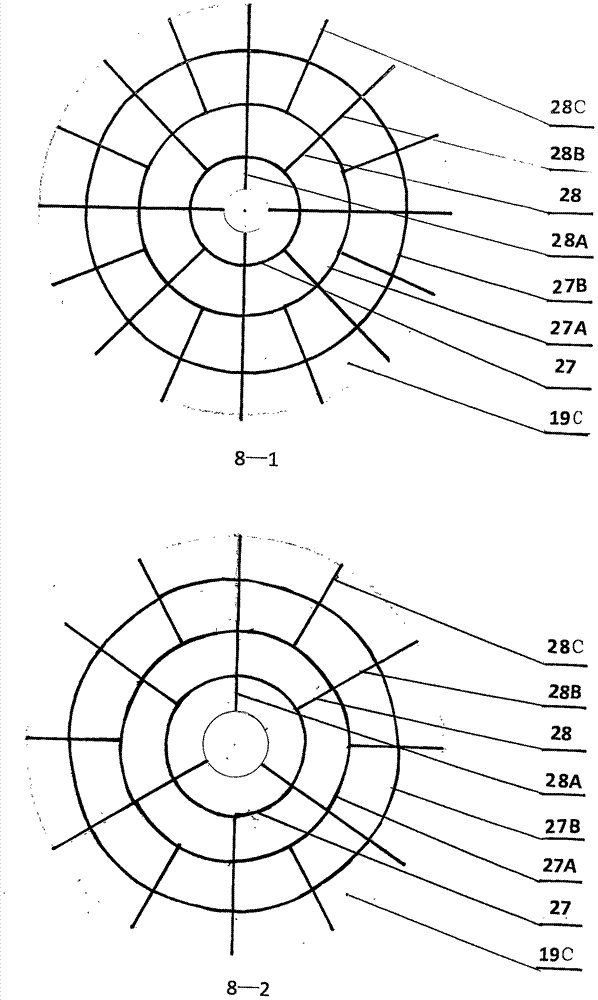

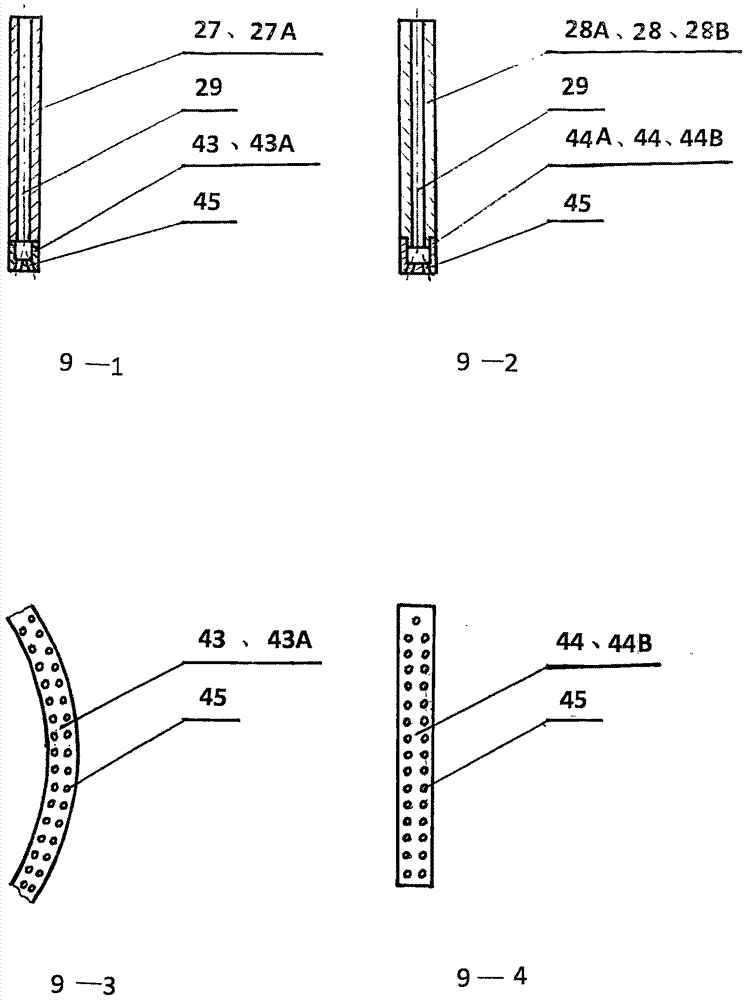

[0039] Figure 1 to Figure 9 It is a preferred embodiment of the present invention for a group of large diameter rocket thrust chambers that use exhaust regeneratively to cool the diaphragm.

[0040] Such as figure 1 , figure 2 with image 3 As shown, a large-diameter basic type thrust chamber is composed of a head 1, a body 2 and a partition 3 and welded as a whole. The connecting parts of the head 1 and these three parts include a bearing seat 4, a flange 5, a porous inner cone shell 6, an outer cone shell 7, a turbine exhaust introduction pipe 8, a first bearing connector 9, a second bearing Force connector 9A, third load-bearing connector 9B, connection collection ring 10, injector plate 11, injection arc section plate group 12, injection radial plate 13, head-body connecting plate 14, ignition fuel collector 15 and ignition fuel enters tube 16. The head 1 is a reinforced double-cone shell big head 1A that adds a third load-bearing connector 9B to more firmly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com