Low noise control method

A control method and low-noise technology, applied to parts of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve the problem of being unable to reduce low- and medium-frequency noise and high-frequency noise at the same time, Achieve the effect of improving passive acoustic characteristics, simple structure and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

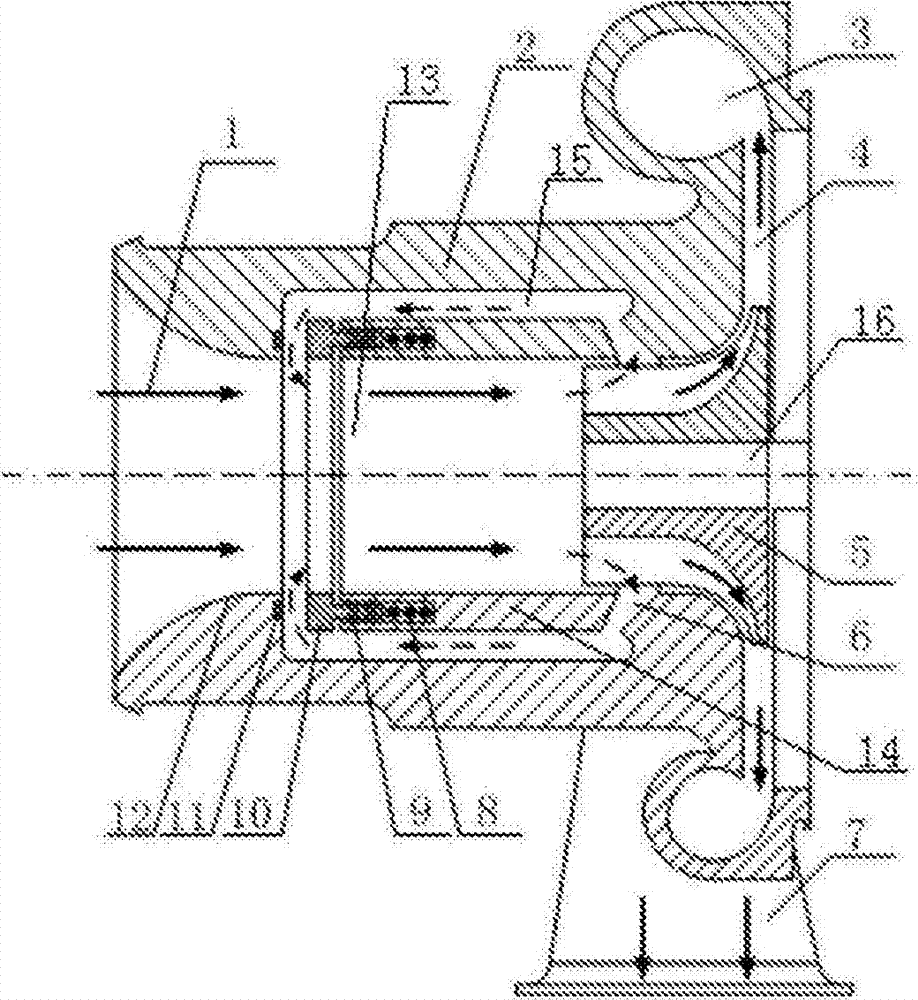

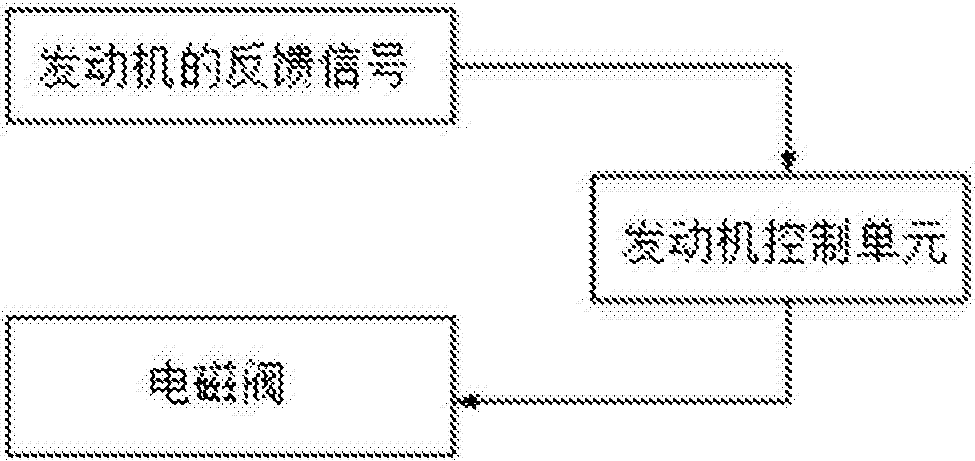

[0020] Such as figure 1 As shown, a supercharger system provided in this embodiment includes a compressor housing 2 and a rotor, the rotor is fixed in the compressor housing 2 through a rotating shaft 16, and the space between the compressor housing 2 and the rotor blades 5 of the rotor is There is an annular gap, the compressor housing 2 is provided with a compressor inner wall 14, the compressor inner wall 14 encloses an intake cavity 13, and the intake cavity 13 communicates with the annular gap; the compressor housing 2 and the compressor inner wall 14 Form the airflow channel 15 that is arranged along the direction of the airflow in the intake cavity 13 between them, the inlet of the airflow channel 15 communicates with the annular gap, and the outlet of the airflow channel 15 communicates with the air inlet of the intake cavity 13; on the compressor inner wall 14 There is an actuator for allowing or preventing the airflow from flowing through the outlet of the airflow ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com