One-way valve with flow monitor

A monitor and one-way valve technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve the problems of time-consuming, complicated installation, low efficiency, etc., and achieve the effect of low cost, simple operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

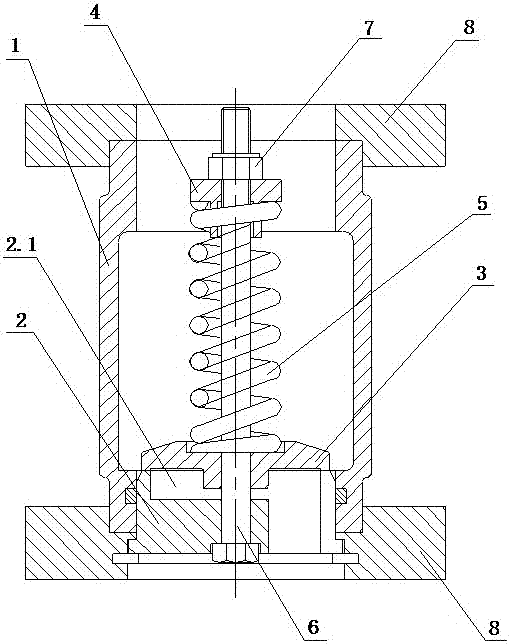

[0011] see figure 1 , the present invention relates to a check valve with a flow monitor, comprising a valve body 1, a valve seat 2 is fixed inside the valve body 1, an oil passage hole 2.1 is opened on the valve seat 2, and the valve seat 3 is provided with There is a spring seat 3, the bottom of the spring seat 3 covers the oil passage hole 2.1, a spring sleeve 4 is arranged above the spring seat 3, a spring 5 is arranged between the spring seat 3 and the spring sleeve 4, and the valve The seat 2, the spring seat 3 and the spring sleeve 4 are fixed through the bolt 6 from bottom to top, the top of the bolt 6 is provided with a lock nut 7, and the lock nut 7 is used to fix the bolt 6, and the valve body 1 Both the bottom and the top are fixed with flanges 8, and the flanges 8 are used to fix the one-way valve with flow monitor on the oil pipe and the flange of the hydraulic machine. The rear side pipeline of the valve body 1 is provided with The flow monitor can monitor the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap