Nondestructive testing enhancement method of internal defects of composite carbon fiber plate

A technology of composite carbon fiber and internal defects, applied in the direction of material defect testing, etc., can solve problems such as hidden dangers of engineering accidents, delamination and fracture, and unstable quality of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A non-destructive detection method for internal drawing defects of a composite carbon fiber plate, the method comprising:

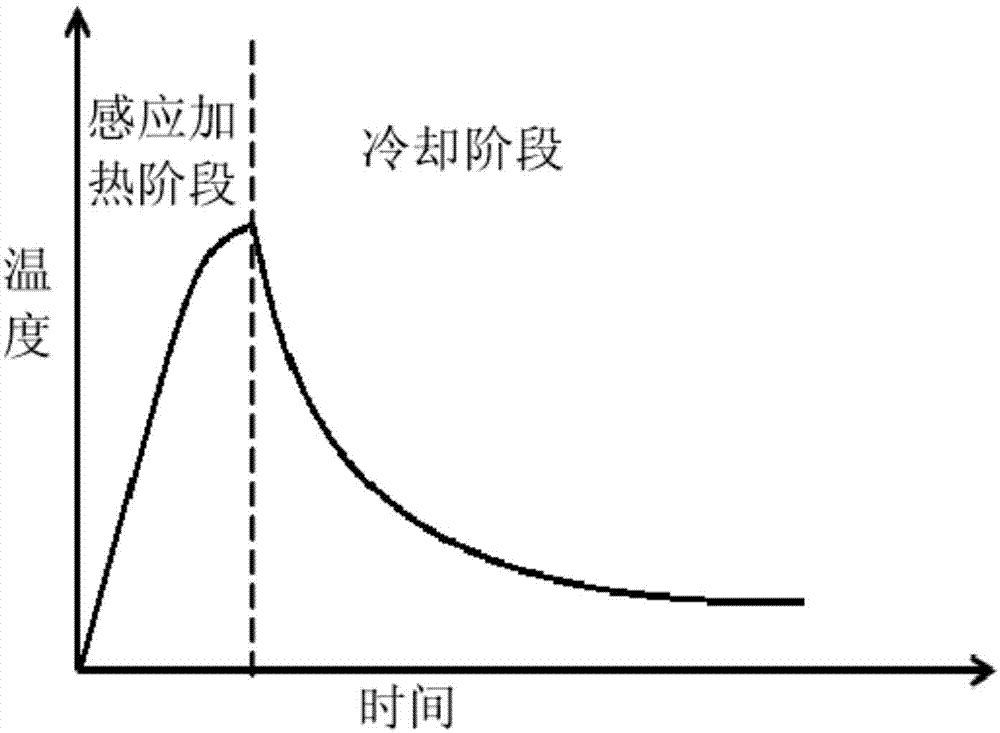

[0029] Step 1: For the multi-frame images obtained, select the part of the images where the temperature of the material changes significantly, that is, the rising stage and part of the falling stage of the material temperature, and select the first 160 frames of images.

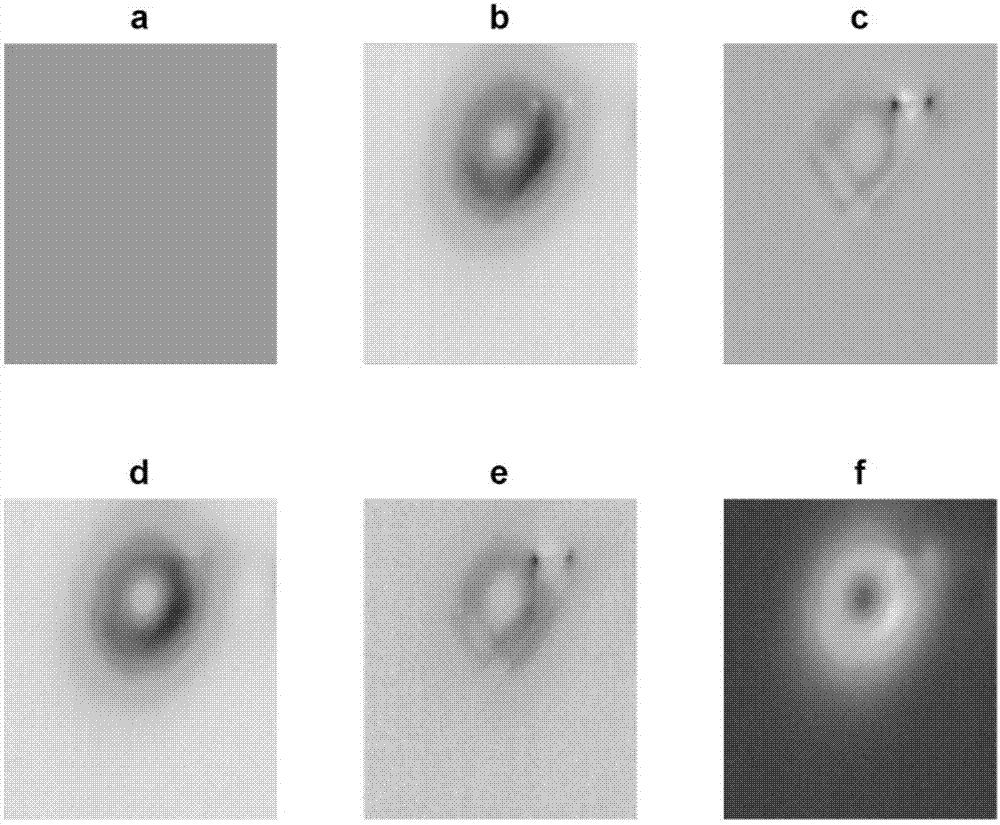

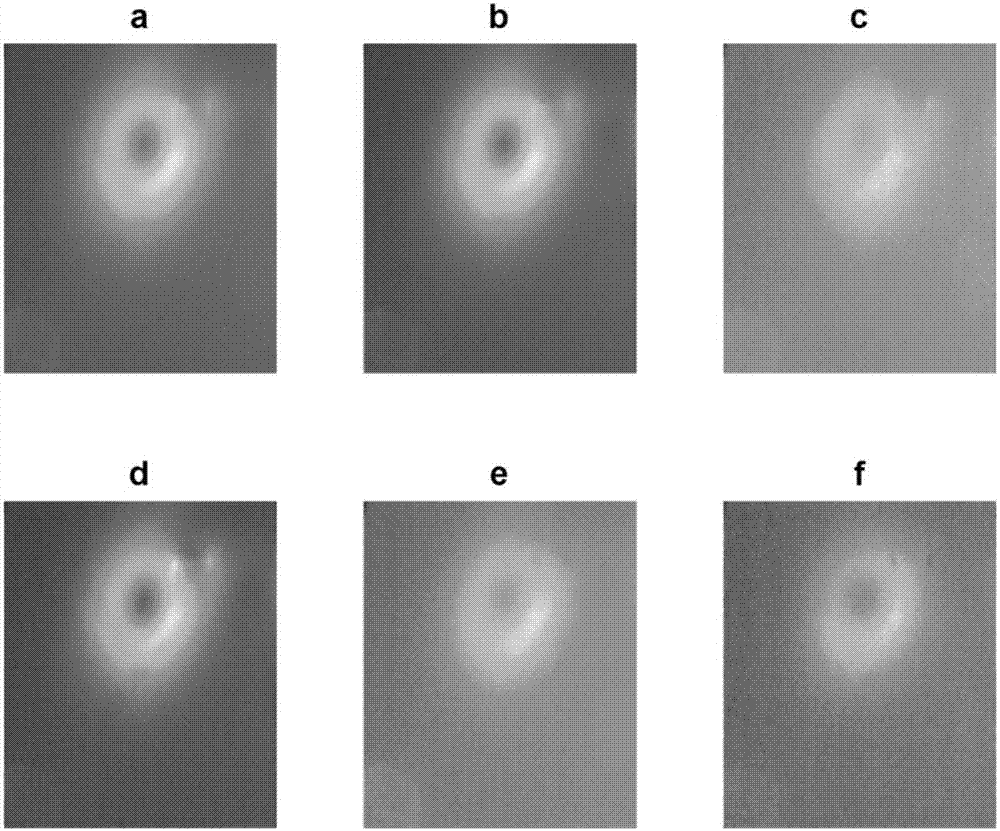

[0030] Step 2: Perform thermal diffusion suppression processing on each selected image.

[0031] Step 2.1: Normalize the image to be processed, and set the convolution kernel alpha 1 、α 2 Indicates the thermal diffusivity, α 1 = 0.2, α 2 =0.12,

[0032] convolution kernel The number of k in is 16; let the first restored image be the image to be processed after normalization, and the initial i is 1;

[0033] Step 2.2.1: Convolve the ith restored image with H as the convolution kernel;

[0034] Step 2.2.2: Divide the normalized image points by the convolved image in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com