DC bus frequency converting control circuit employing small-capacitance capacitor and frequency conversion device

A technology of small-capacity capacitors and DC bus, which is applied in the direction of AC motor control, control systems, circuit devices, etc., can solve the problems of increasing grid load, grid safety, high cost of frequency conversion control circuits, and unstable DC bus voltage, etc., to improve reliability performance, achieve stable design, and avoid overvoltage damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present application will be described in further detail below in conjunction with the accompanying drawings.

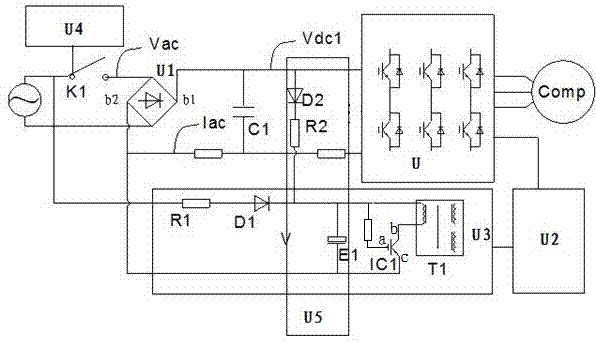

[0015] like figure 1 As shown, the DC bus small-capacity capacitor frequency conversion control circuit proposed in this application includes a rectifier U1, a DC bus, a small-capacity capacitor C1, an inverter U, an inverter control module U2, a power supply switch K1, and a power supply for the inverter control module. The circuit U3 and the power supply control module U4; the two output terminals b1 and b2 of the rectifier U1 are connected to the DC bus, and the small-capacity capacitor C1 and the inverter U are sequentially connected in parallel with the DC bus; the power supply switch K1 is connected between the rectifier U1 and the AC input AC; The power supply circuit U3 of the inverter control module is connected to the AC input AC to provide working power for the inverter control module U2; the power supply co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com