Bending device for scrap steel plate recovery and method for recycling scrap steel plate by using device

A bending device and steel plate technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of high design cost and processing cost, affecting the effect of scrap steel plate treatment, and unfavorable market promotion of the device, so as to reduce the design cost and processing cost. Convenient packaging process, clever design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

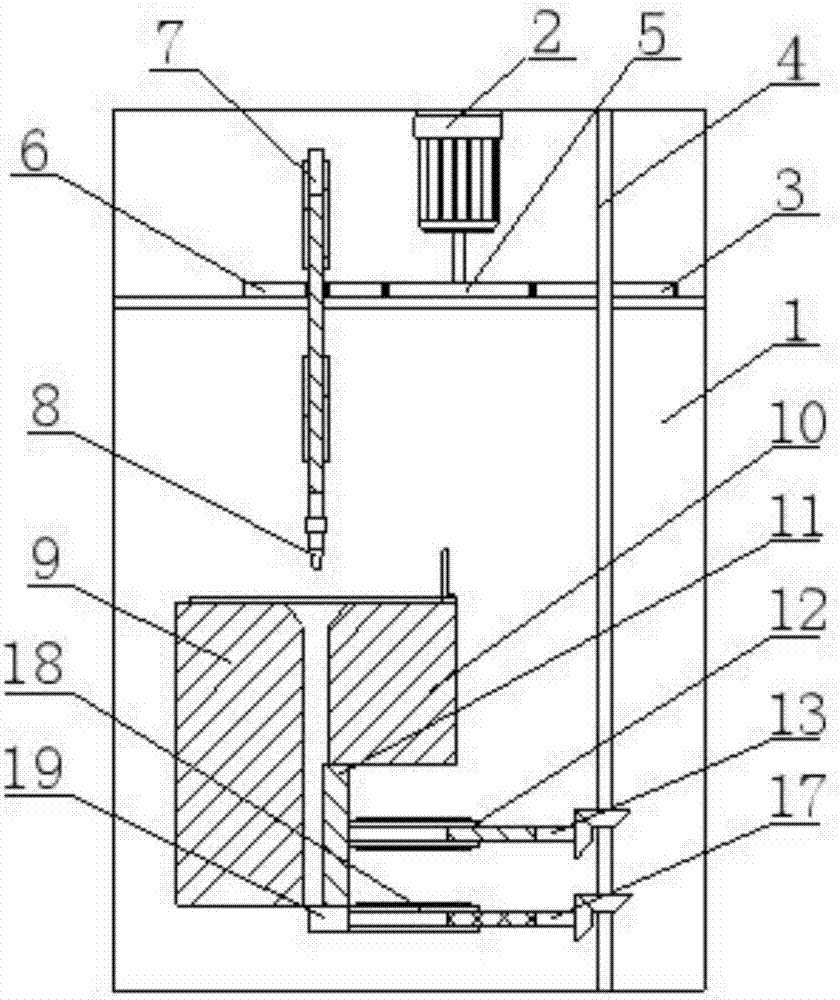

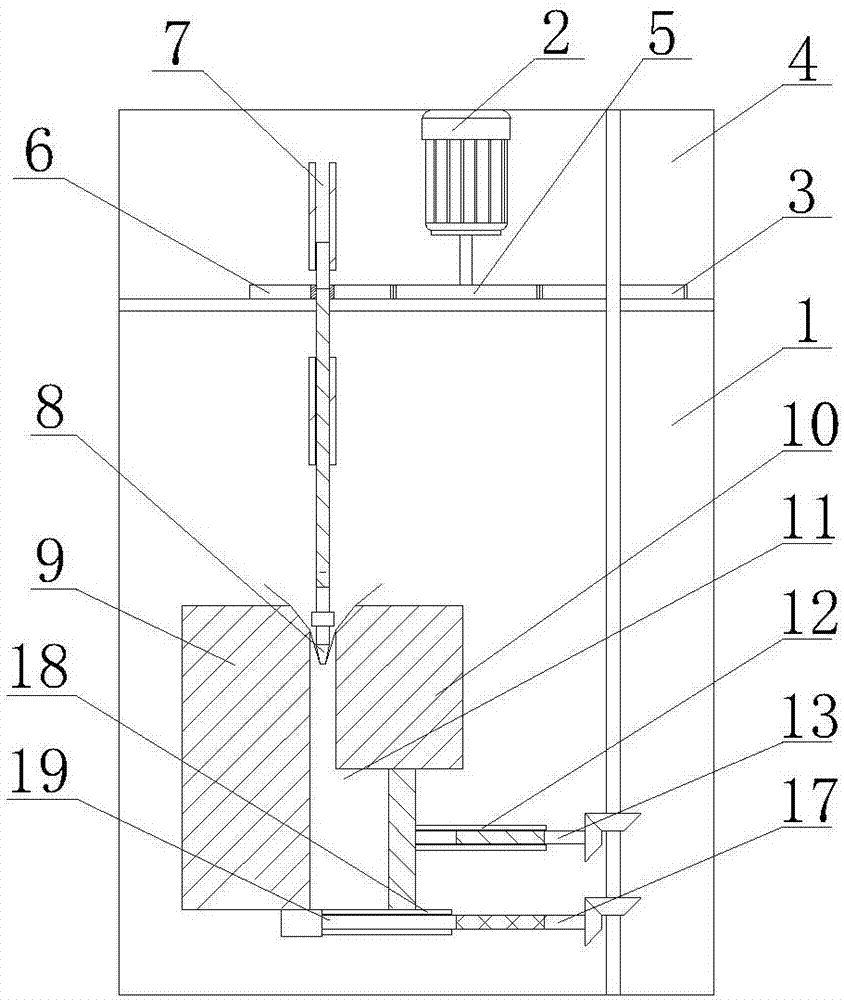

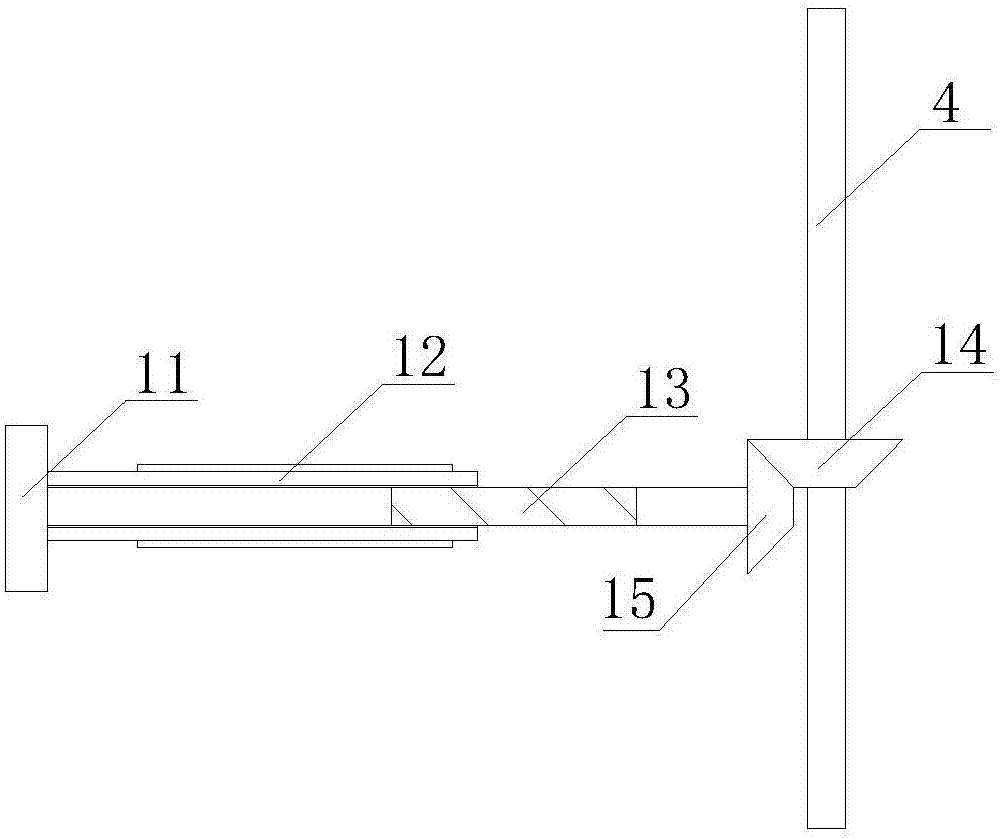

[0041] A bending device for recycling scrap steel plates proposed by the present invention includes a frame 1, a workbench connected to the frame 1, a bending unit and an extrusion unit, and the bending unit is used to carry out scrap steel plates on the workbench Bending processing, the extruding unit is used for extruding the scrap steel plate after bending; the workbench includes a left support plate 9 and a right support plate 10, and there is a The passage through which scrap steel plates pass, the top surface of the left support plate 9 and the top surface of the right support plate 10 are on the same plane, and the bottom surface of the left support plate 9 is located below the bottom surface of the right support plate 10; the bending unit includes a stamping knife 8, a rotating The stamping rod 7 connected to the stamping knife 8 is driven by the driving mechanism to move up and down, and the stamping knife 8 is located directly above the gap between the left support pl...

Embodiment 2

[0060] The invention also discloses a method for recycling scrap steel plates, comprising the following steps:

[0061] (1) Carry out surface pretreatment on the scrap steel plate to remove the impurities attached to the scrap steel plate surface. After cleaning, put the scrap steel plate on the workbench, and make the two ends of the scrap steel plate supported by the left support plate 9 and the right support plate respectively. 10 supports;

[0062] (2) Start the drive mechanism, the drive mechanism drives the stamping knife 8 to go down, at the same time, the extrusion plate 11 is driven by the drive mechanism to move away from the left support plate 9, and the support plate is driven by the drive mechanism to approach the left support plate 9 moves on one side. During the downward process of the stamping knife 8, the stamping knife 8 contacts the scrap steel plate and presses down on the scrap steel plate. The scrap steel plate is affected by the stamping knife 8, the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com