System for removing induction voltage in coal conveyor program control circuit

A technology of induced voltage and coal conveyer, applied in conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as the inability to fundamentally eliminate thermal power plants, the inability to continue the process, and the inability of cables to be reliably grounded. Achieve the effect of improving overall safety and reliability, avoiding fire, and eliminating induced voltages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

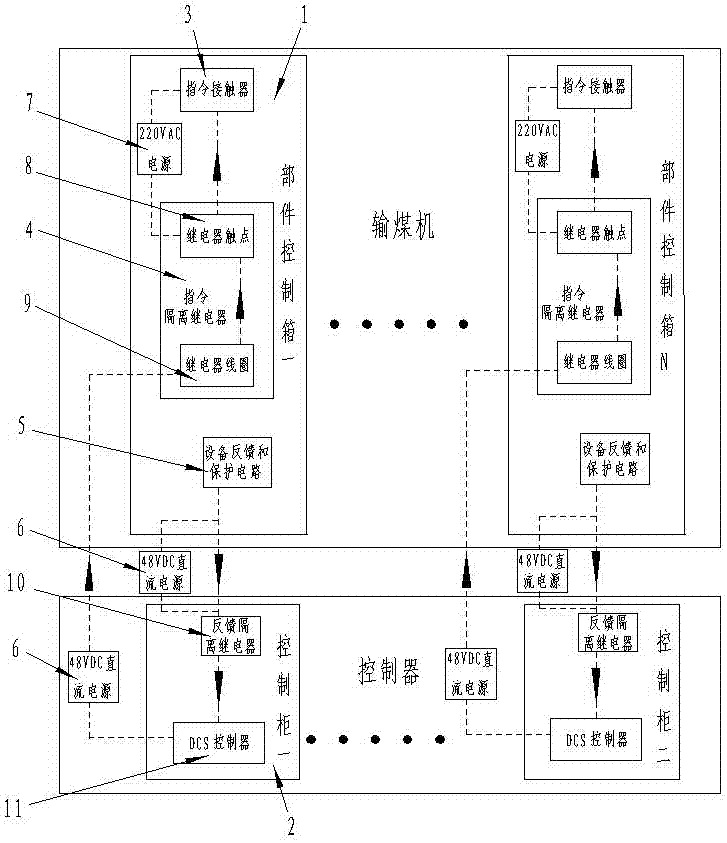

[0010] Such as figure 1 As shown, a system for eliminating the induced voltage in the program-controlled circuit of the coal feeder, the program-controlled equipment of the coal feeder includes several component control boxes 1 and several control cabinets 2 corresponding to the component control boxes 1, and each component control box 1 Including command contactor 3, command isolation relay 4, equipment feedback and protection circuit 5, 48VDC DC power supply 6 and 220VAC AC power supply 7, command isolation relay 4 includes relay contacts 8 and relay coils 9; each control cabinet of the controller 2 includes a feedback isolation relay 10 and a DCS controller 11; wherein, the equipment feedback and protection circuit 5 is connected to the feedback isolation relay 10 through an unshielded signal cable to form a feedback protection loop, and the feedback protection loop is powered by a 48VDC DC power supply 6. If an early warning occurs on a certain device of the machine, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com