A method for adjusting the alignment between the coke charging position of the scp machine and the center line of the carbonization chamber

A technology of alignment adjustment and center line, which is applied in the field of coking, can solve problems such as the difficulty in detecting and adjusting the alignment accuracy of the center of the carbonization chamber, and the inconsistency of the coke oven machine side, and achieve the effect of avoiding inaccurate alignment and accurate positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

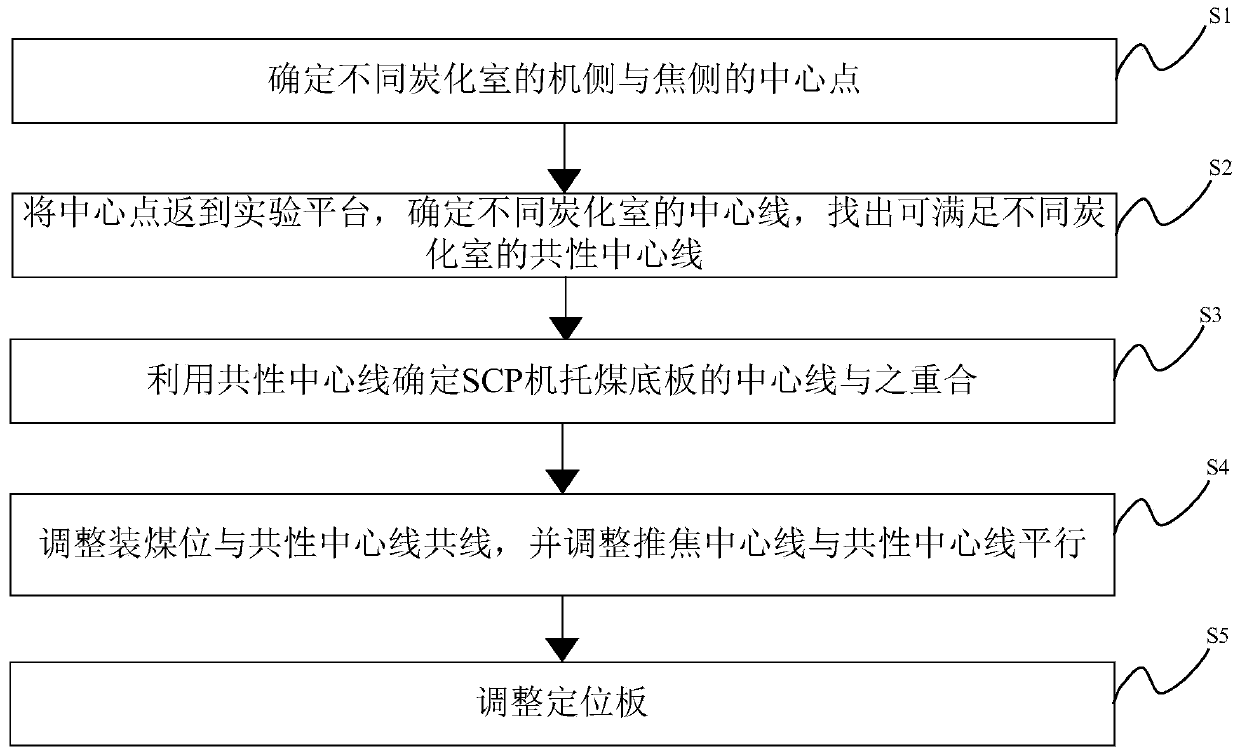

[0047] Such as figure 1 As shown, the invention discloses a method for adjusting the alignment between the coke pushing coal charging level of the SCP machine and the center line of the carbonization chamber, which includes the following steps:

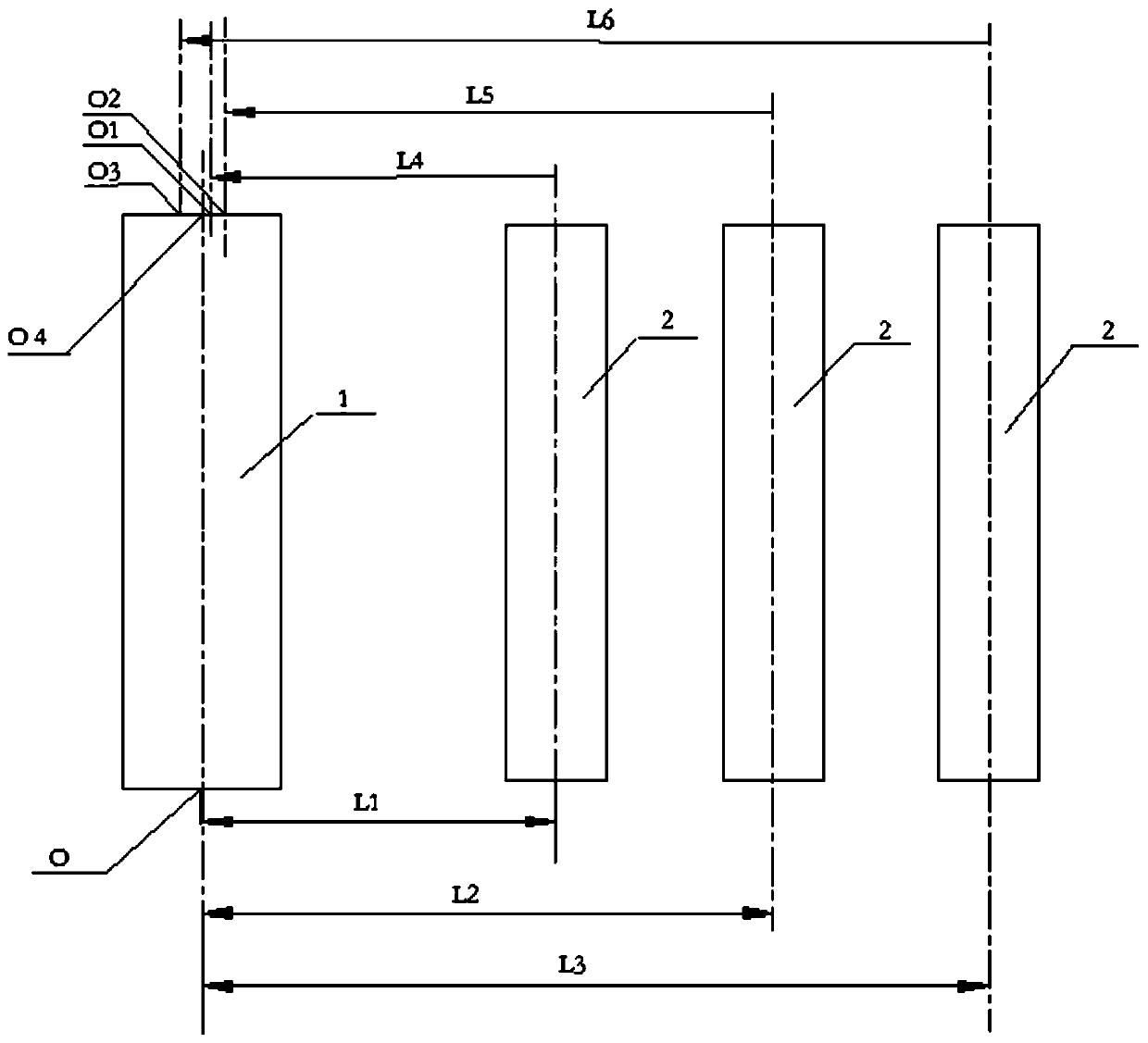

[0048] Step S1: Determine the center points of the machine side and the coke side of different carbonization chambers 2 .

[0049] Since the actual center line of the carbonization chamber 2 cannot be measured and determined during production, the width data of 10 furnace frames 9 are randomly measured for each of the 2 coke ovens on site to find out the measurement center reference point. Through the measurement data, the data of the furnace frame 9 They are almost identical, and the center point of the furnace frame 9 can be used as a measurement reference point.

[0050]Since the actual center line of the carbonization chamber 2 cannot be measured and determined during production, the width data of 10 frames 9 of coke ovens 1 and ...

Embodiment 2

[0072] In the second embodiment provided by the present invention, the method for adjusting the alignment between the coke pushing coal level of the SCP machine and the center line of the carbonization chamber is similar to the method for adjusting the alignment between the coke pushing coal level of the SCP machine and the center line of the carbonization chamber in Embodiment 1. , I will not repeat the similarities, but only introduce the differences.

[0073] In this embodiment, it is specifically disclosed that before step S1, it also includes:

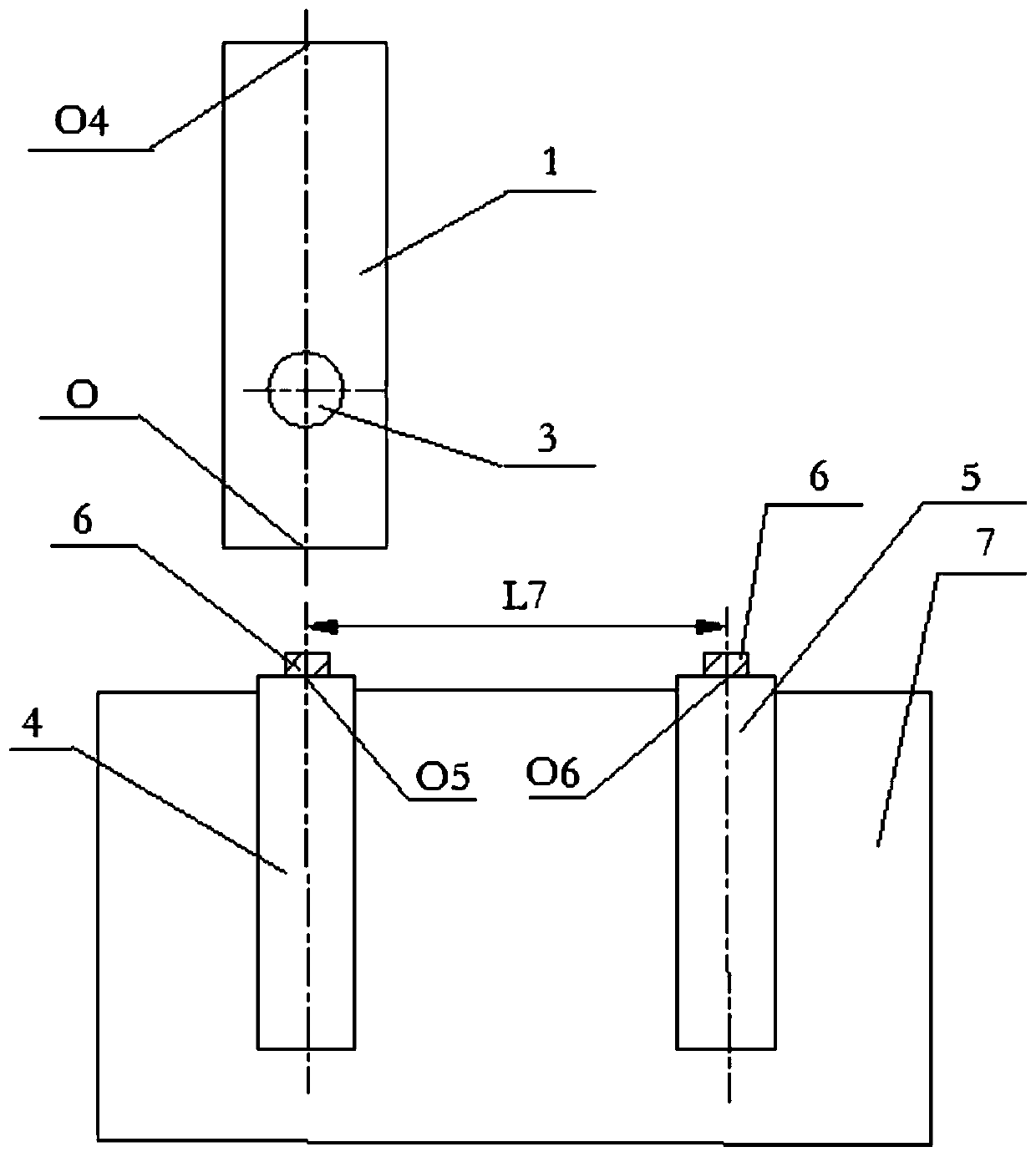

[0074] Step S6: Install the U-shaped probe 6 and the positioning plate 8, and adjust the positioning plate 8 to complete the calibration of the U-shaped probe 6.

[0075] Step S6 specifically includes the following steps:

[0076] Step S61: Install the U-shaped probe 6 at a preset position, place the positioning plate 8 in the U-shaped probe 6, and test the data transmission reliability of the radio frequency identification anten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com