Electronic speed controller controlled variable-pitch rotor system module and helicopter

A technology of electronic control and system modules, which is applied in the field of helicopters, can solve the problems of large complexity of rotor power system and variable pitch control mechanism, hidden dangers of reliability and safety, and inconvenient system assembly, so as to reduce processing and assembly time, Avoid the effect of stability and improve battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

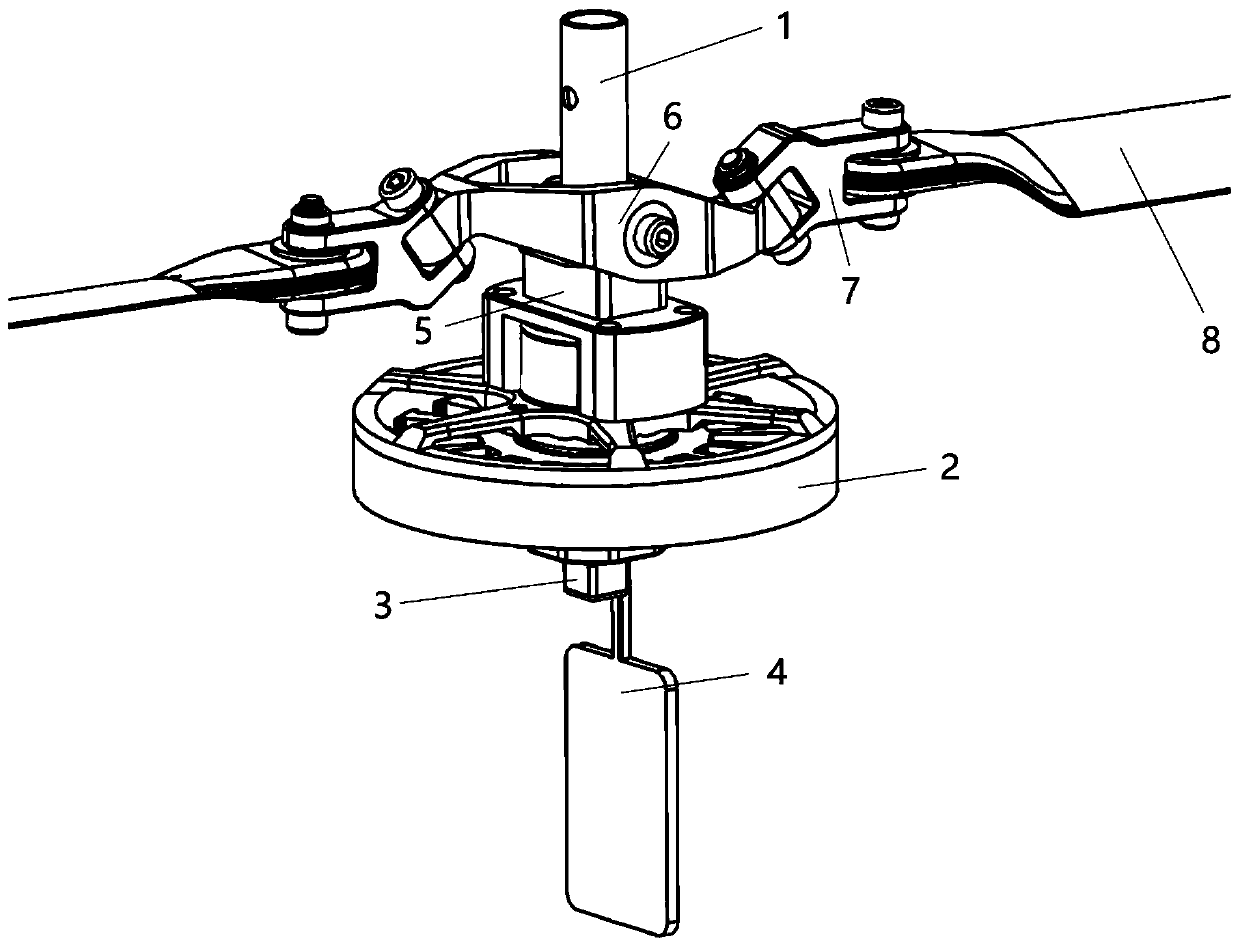

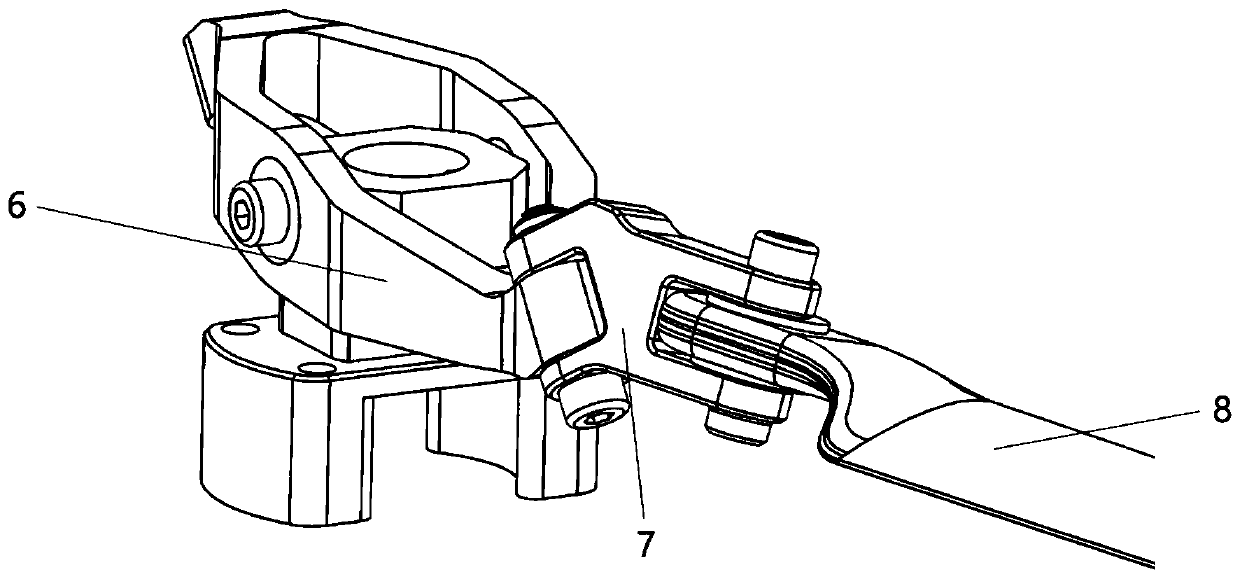

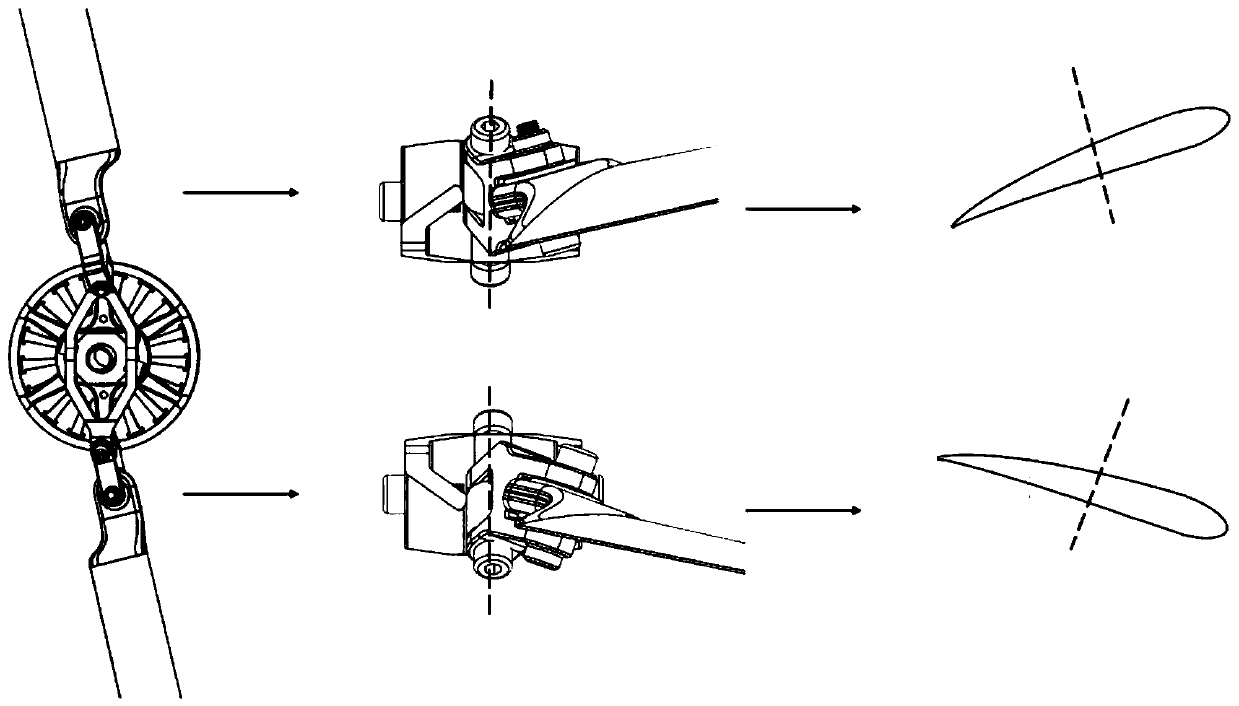

[0051] Such as figure 1 Shown is a variable-pitch rotor system module disclosed in this embodiment. One end of the lead-lag variable-pitch clip 7 is fixedly connected to one end of the blade 8, and the other end of the lead-lag variable-pitch clip 7 is connected to the flapping connector 6. One end of the waving connector 6 is hinged with the propeller hub 5; the propeller hub 5 is fixedly connected with the power output shaft of the power module 2; in the rotor system, two blades 8, two A lead-lag variable pitch propeller clip 7; the angle measurement unit 3 is to measure the rotation position angle of the power module 2, and is installed coaxially with the power module 2; the electronic governor 4 can control the power module 2 at various positions in the rotation, and change the output Torque; the angle measurement unit 3 detects the angle information of the rotational position of the power module 2, and after obtaining the angle information, the electronic governor 4 contr...

Embodiment 2

[0060] This embodiment discloses a coaxial double-deck variable pitch helicopter, such as Figure 6 to Figure 8 One configuration is shown. The coaxial double-deck variable-pitch helicopter is equipped with two sets of variable-pitch rotor system modules controlled by electric regulation as in Embodiment 1; the two sets of variable-pitch rotor system modules controlled by electric regulation are coaxially assembled.

[0061] This embodiment discloses a coaxial double-deck variable-pitch helicopter, and its coaxial assembly method is any one of the following four types:

[0062] 1. If Image 6 As shown, the two sets of power modules 2 are external;

[0063] 2. If Figure 7 As shown, the two sets of power modules 2 are all placed in the middle;

[0064] 3-4, such as Figure 8 As shown, one set of power modules 2 is placed in the middle, and the other set of power modules 2 is placed up or down.

[0065] In the coaxial double-deck variable-pitch helicopter disclosed in this...

Embodiment 3

[0067] This embodiment discloses a coaxial single-deck variable pitch helicopter, such as Figure 9 to Figure 12 One configuration is shown. The coaxial single-layer variable-pitch helicopter includes two sets of rotor systems; the two sets of rotor systems are coaxially assembled; one of them is configured as the variable-pitch rotor system module controlled by the electric control of Embodiment 1, and the other set of rotor systems is fixed-axis without variable pitch rotor system; such as Figure 5 The fixed-axis non-variable-pitch rotor system includes a central shaft 1 , a power module 2 , a propeller hub assembly 9 , a propeller clip 10 , and a propeller blade 8 . Wherein, the central shaft 1 is fixedly connected with the power module 2; the torque output shaft of the power module 2 is fixedly connected with the hub assembly piece 9; The roots are hinged.

[0068] This embodiment discloses a coaxial single-deck variable-pitch helicopter, and its coaxial assembly metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com