An effective method to improve the plastic formability of high-strength mg-gd-y-nd-zr magnesium alloys

A technology for plastic forming and magnesium alloys, which is applied in the field of plasticity improvement of high-strength magnesium alloys, can solve the problems of poor plastic forming ability of high-strength magnesium alloys, and achieve the effects of improved coordination of plastic deformation, simple equipment, and simple processing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, an effective method for improving the plastic forming ability of the high-strength Mg-Gd-Y-Nd-Zr magnesium alloy is as follows:

[0044]Ⅰ), the lithium-containing Mg-7%Gd-5%Y-1%Nd-0.5%Zr-10%Li alloy composition used

[0045] Use lithium-containing high-strength Mg-7%Gd-5%Y-1%Nd-0.5%Zr-10%Li alloy, its chemical composition (percentage by weight) is: gadolinium content is 7%; yttrium content is 5% %; neodymium content 1%; zirconium content 0.5%; lithium content 10%; magnesium balance.

[0046] Ⅱ), alloy smelting

[0047] The Mg-Gd-Y-Nd-Zr alloy and pure lithium ingots are melted in a vacuum smelting furnace, and the alloy is smelted under the protection of argon, and the temperature is kept at 770°C for 4 hours, and then cast in the furnace .

[0048] Ⅲ), homogenization treatment

[0049] The high-strength Mg-7%Gd-5%Y-1%Nd-0.5%Zr-10%Li alloy is kept at 400°C for 8 hours and tightly wrapped with aluminum foil to prevent the alloy from burning due to...

Embodiment 2

[0059] In this embodiment, an effective method for improving the plastic forming ability of the high-strength Mg-Gd-Y-Nd-Zr magnesium alloy is as follows:

[0060] Ⅰ), the lithium-containing Mg-9%Gd-6%Y-1.5%Nd-0.5%Zr-10%Li alloy composition used

[0061] Use lithium-containing high-strength Mg-9%Gd-6%Y-1.5%Nd-0.5%Zr-10%Li alloy, its chemical composition (weight percentage) is: gadolinium content is 9%; yttrium content is 6% %; neodymium content 1.5%; zirconium content 0.5%; lithium content 10%; magnesium balance.

[0062] Ⅱ), alloy smelting

[0063] Same as Example 1.

[0064] Ⅲ), homogenization treatment

[0065] Same as Example 1.

[0066] Ⅳ), plastic deformation

[0067] Same as Example 1.

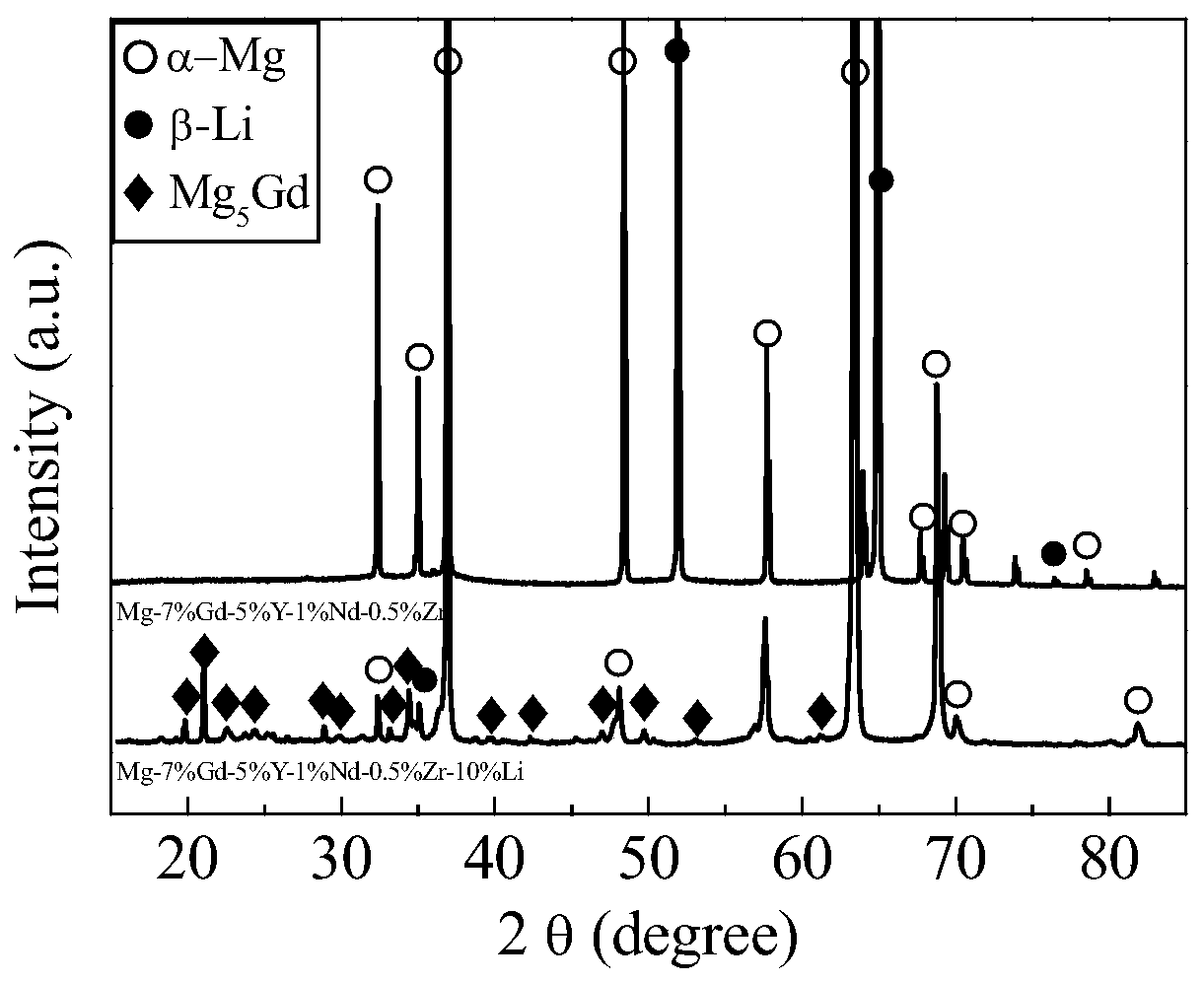

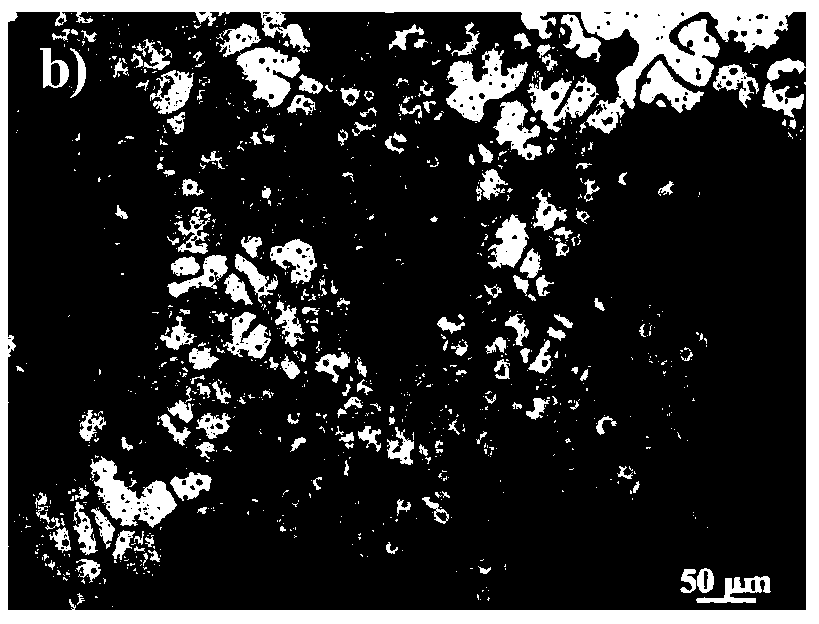

[0068] Ⅴ) Microstructure characterization

[0069] The tissue observation method is the same as in Example 1. XRD results show that the sample of Example 2 mainly contains β-Li, α-Mg and Mg5Gd phases. Optical observation results show that the volume fraction of the quasi-crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com