Powder material weighing method and weighing device

A technology of powder materials and weighing devices, which is applied in the direction of measuring devices, weighing, instruments, etc., can solve the problems of chronic poisoning of workers, excessive powder materials, endangering the health of workers, etc., and achieve continuous and stable production and operation. Satisfy the effect of accurate weighing of ingredients and guarantee of intrinsically safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

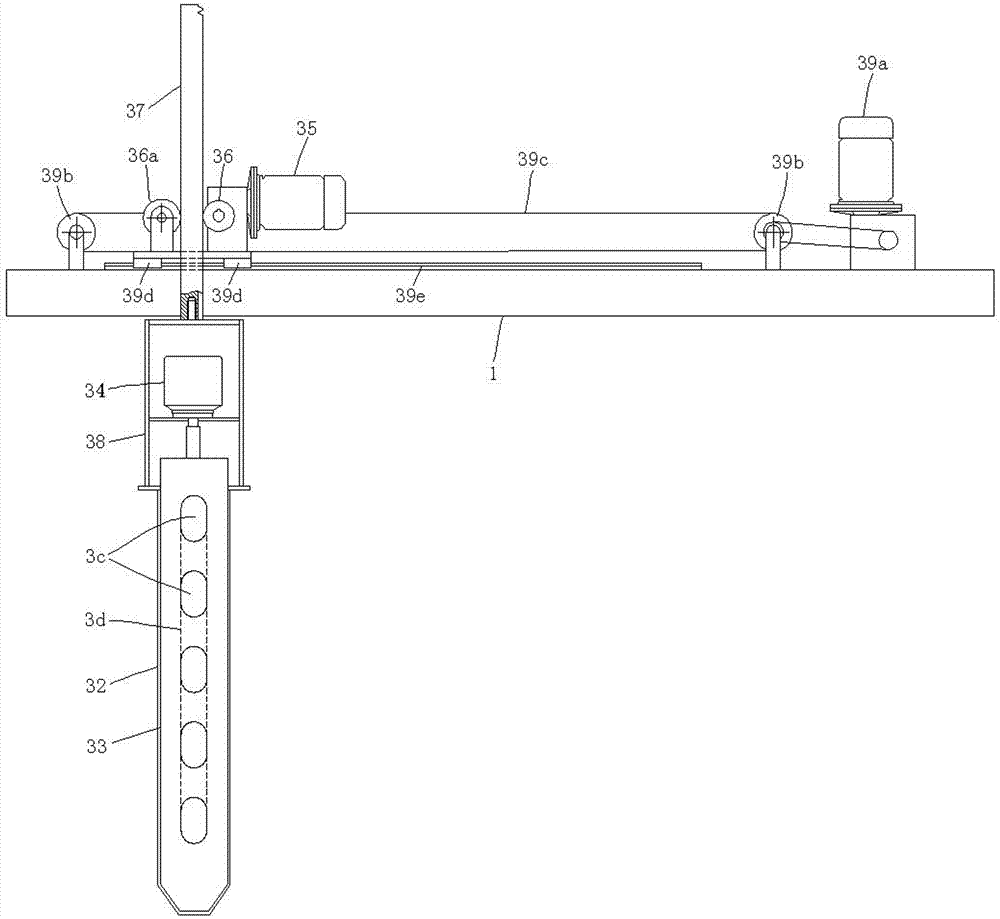

[0035] As yet another preferred embodiment of the present invention, the automatic take-out unit C includes a camera installed above or in the weighing container 21, a conventional cantilevered three-axis manipulator and a recycle bin 31, the camera and the recycle bin 31 are not shown in the figure A cantilevered three-axis manipulator, the camera and the cantilevered three-axis manipulator are electrically connected to the control and data processing unit E respectively. When working, the camera directly judges the powder accumulation height, and under the control of the control and data processing unit E, the cantilevered three-axis manipulator retrieves the excess powder and puts it into the recovery bucket 31.

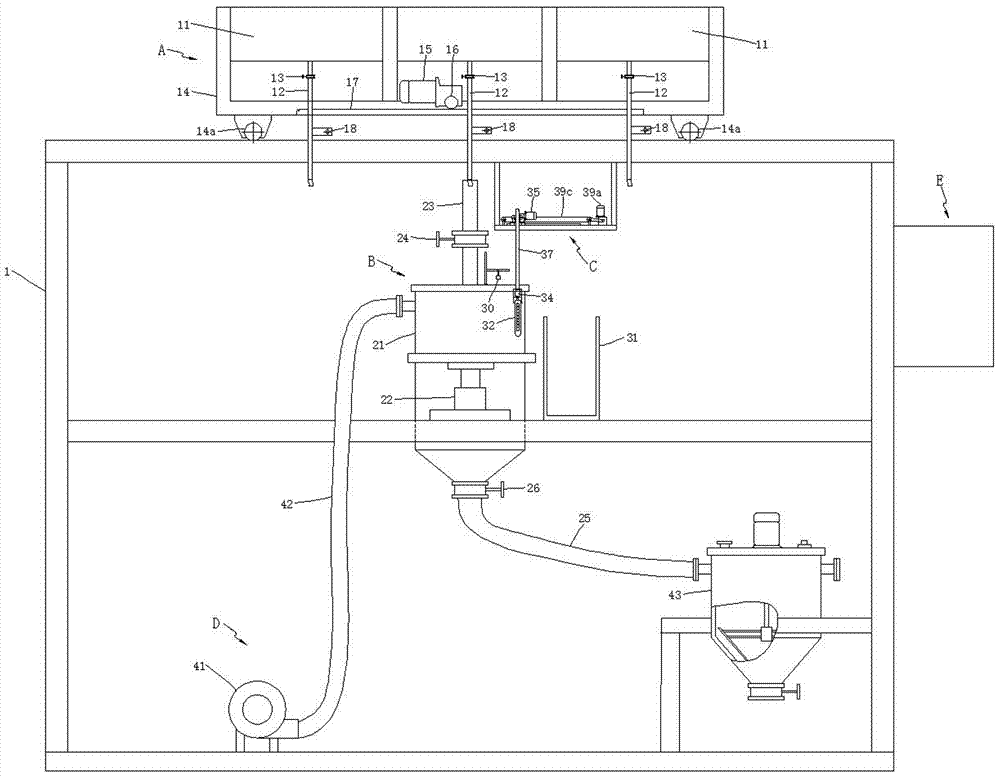

[0036] In the present invention, as figure 1 As shown, the powder storage unit A includes several independent material bins 11 and vertical material bin lowering pipes 12 respectively installed at the bottom of each independent material bin 11. There are three mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com