A material recognition sensor based on a composite capacitive structure and its preparation method

A sensor and capacitive technology, applied in the field of sensors, can solve the problems of no sensor that can measure the dielectric constant and elastic modulus at the same time, the complex structure of the sensor, and the large volume, so as to avoid damage or destruction, reduce costs, and accurately identify materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

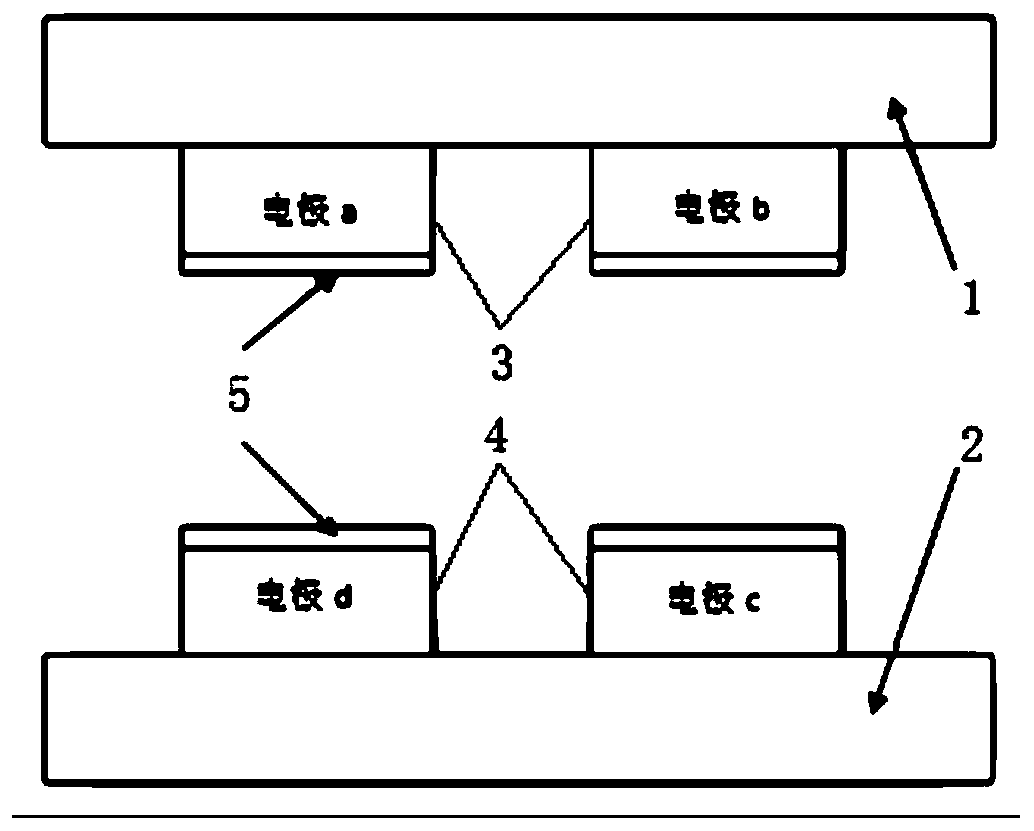

[0036] A material identification sensor based on a composite capacitive structure of the present invention is a composite capacitive structure including an elastic modulus sensor and a dielectric constant sensor. By simultaneously detecting the dielectric constant and elastic modulus of the object to be measured, the object to be measured is The elastic modulus and dielectric constant of the object are used as the judgment parameters for object material identification, and then the material identification is realized.

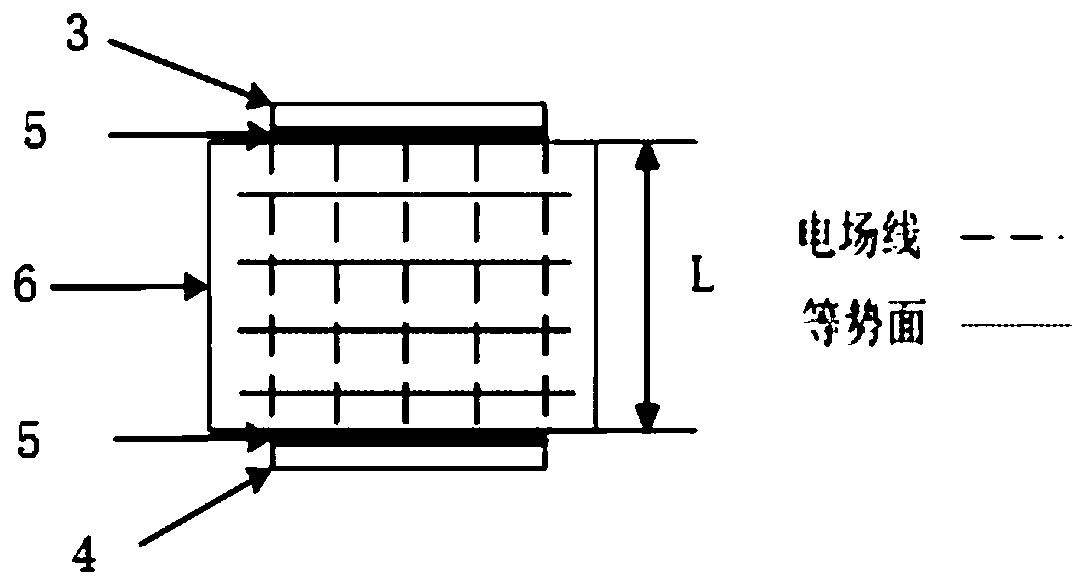

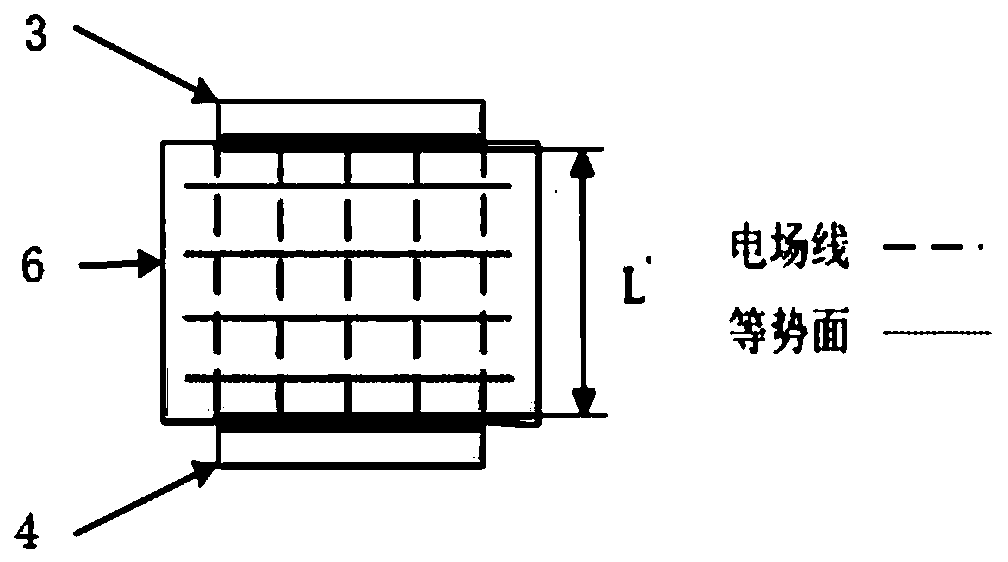

[0037] The elastic modulus sensor is a capacitive structure opposite to the electrode plate. By applying positive and negative voltages on the upper and lower plates, an electric field can be formed, and the object to be measured is placed between the two plates. Since the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com