Ultrasonic probe correction method and system

A technology of correction system and correction method, which is applied in the field of ultrasonic detection, can solve problems such as inaccurate transmission and reception focus, poor image resolution and contrast, and achieve the effect of ensuring accuracy and improving detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

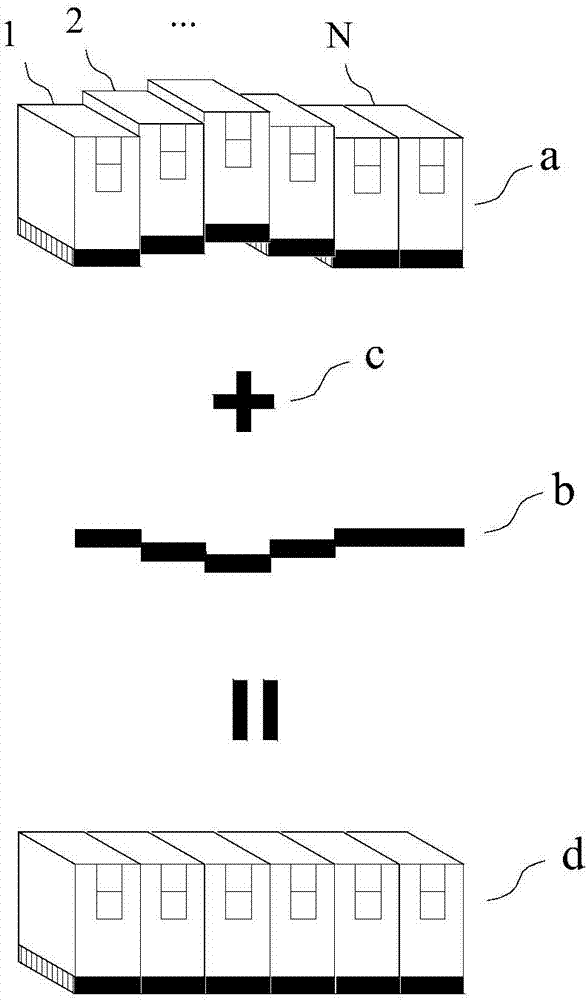

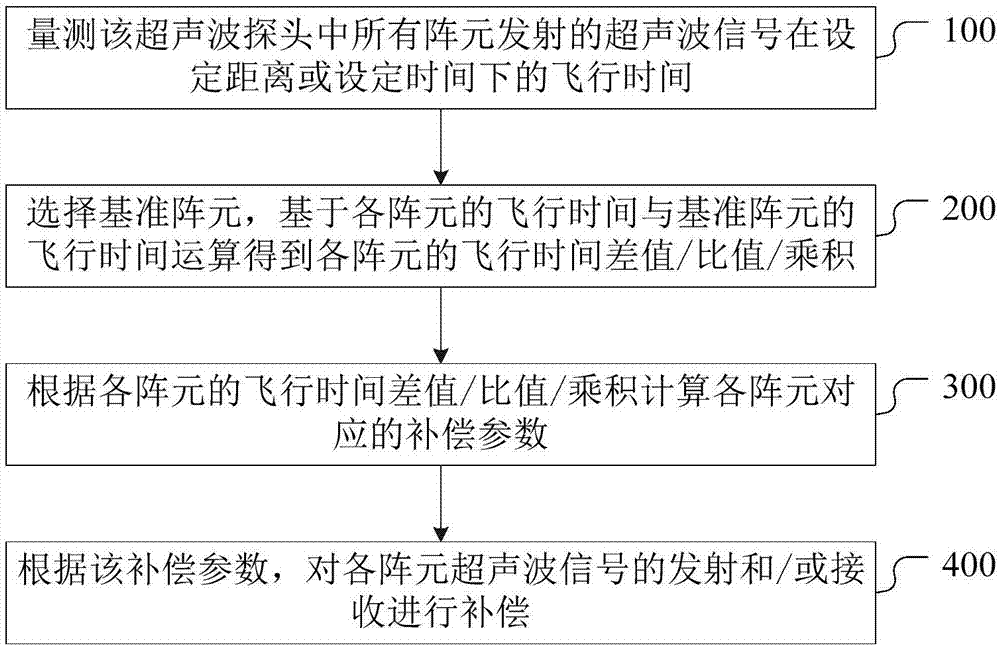

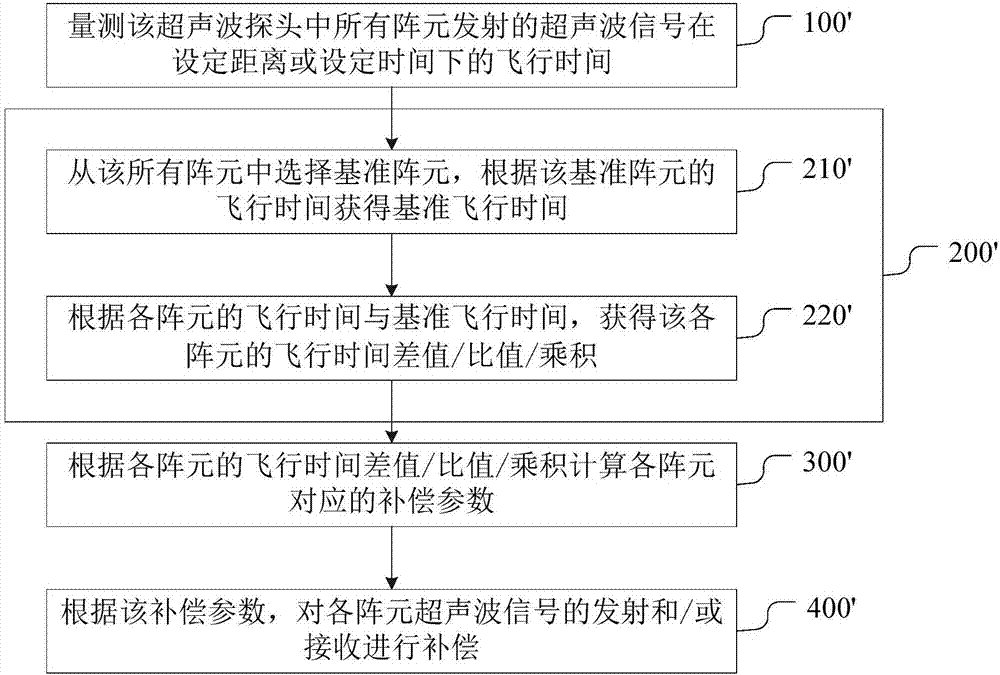

[0038] The invention provides a method for calibrating an ultrasonic probe, which determines the calibration information according to the measurement result, so as to provide the basis for calculating the transmitting and receiving beams of the ultrasonic system. Such as figure 1 As shown, due to the limited process capability of the ultrasonic probe, there are differences between the planes or line planes formed by the array elements of the probe. Taking a one-dimensional linear array probe with N array elements as an example, the arrangement of the array elements is not actually distributed in a straight line. At this time, it is necessary to determine the real distribution parameter a of the plane error through measurement, and perform calculations based on a to obtain correction information b, which can be provided to the ultrasonic system for compensation calculation c, after compensation and correction, the array elements present an ideal linear or planar arrangement d. ...

no. 2 example

[0059] Figure 3A and 3B It is a structural diagram of the correction system of the ultrasonic probe 311 according to the second embodiment of the present invention. The present invention provides a calibration system 30 for an ultrasonic probe 311 , which determines calibration information based on measurement results to provide a basis for calculation of transmitting and receiving beams of the ultrasonic system. The system includes: a measurement module 31 , a control processing module 32 and a compensation module 33 , the measurement module 31 is coupled to the ultrasonic probe 311 , and the control processing module 32 is coupled to the compensation module 33 . The ultrasonic probe 311 to be tested can be a linear array, a phased array or other types of probes, and can be a one-dimensional or more than one-dimensional array.

[0060] The measurement module 31 is used to measure the time-of-flight of the ultrasonic signals emitted by all the array elements in the ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com