Millet dampness-dispelling coarse grain nutritional powder and preparation method thereof

A nutritional powder and dampness-removing technology, applied in the field of deep processing of food, can solve the problems of difficulty in boiling, limited utilization of coix seed, and difficulty in gelatinization of starch, so as to avoid rough taste, be beneficial to health, and reduce gastrointestinal burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A preparation method of millet dehumidification miscellaneous grain nutrition powder, comprising the following steps:

[0059] (1) Selection of raw materials: raw materials include millet, red bean, barley, and red dates. Check whether the raw materials contain hard impurities, insect-eaten and mildewed raw materials, and select the impurities;

[0060] (2) Preparation of fried millet powder

[0061] ① Moisturizing: Moisten the selected small yellow rice, add 10mL of water per kg of small yellow rice, stir evenly, stirring for 2 minutes, put the stirred raw materials into a clean turnover box, and leave it for 10 minutes be usable;

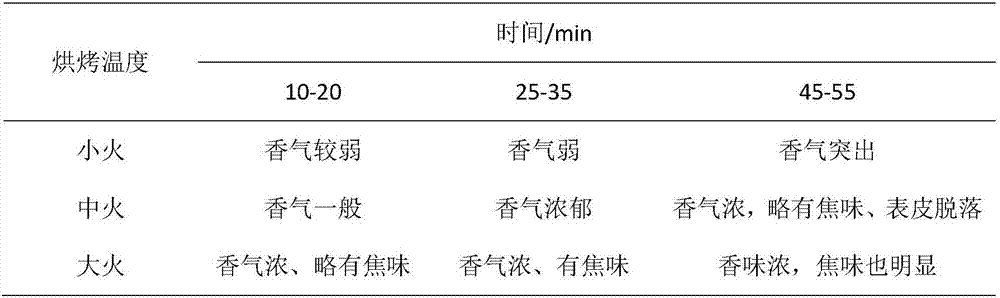

[0062] ②Stir-frying: Set the frying heat of the electric frying oven to medium heat, add the moistened millet, and stir-fry continuously until the millet is apricot-yellow and has the grain aroma of millet. The entire frying time is controlled at 15min;

[0063] ③Crush: Powder the cooled millet with a pulverizer for 30 seconds;

[0064]...

Embodiment 2

[0089] A preparation method of millet dehumidification miscellaneous grain nutrition powder, comprising the following steps:

[0090] (1) Selection of raw materials: raw materials include millet, red bean, barley, and red dates. Check whether the raw materials contain hard impurities, insect-eaten and mildewed raw materials, and select the impurities;

[0091] (2) Preparation of fried millet powder

[0092] ① Moisturizing: Moisten the selected small yellow rice, add 15mL of water per kg of small yellow rice, stir evenly, stirring for 3 minutes, put the stirred raw materials into a clean turnover box, and leave it for 20 minutes be usable;

[0093] ②Stir-frying: Set the frying heat of the electric frying oven to medium heat, add the moistened millet, and stir-fry continuously until the millet is apricot-yellow and has the grain aroma of millet. The entire frying time is controlled at 30min;

[0094] ③Crush: Powder the cooled millet with a pulverizer for 40 seconds;

[0095]...

Embodiment 3

[0120] A preparation method of millet dehumidification miscellaneous grain nutrition powder, comprising the following steps:

[0121] (1) Selection of raw materials: raw materials include millet, red bean, barley, and red dates. Check whether the raw materials contain hard impurities, insect-eaten and mildewed raw materials, and select the impurities;

[0122] (2) Preparation of fried millet powder

[0123] ① Moisturizing: Moisten the selected small yellow rice, add 12mL of water per kg of small yellow rice, stir evenly, stirring for 2.5 minutes, put the stirred raw materials into a clean turnover box, and leave it for 15 minutes be usable;

[0124] ②Stir-frying: Set the frying heat of the electric frying oven to medium heat, add the moistened millet, and stir-fry continuously until the millet is apricot-yellow and has the grain aroma of millet. The entire frying time is controlled at 20min;

[0125] ③Crush: Powder the cooled millet with a pulverizer for 35 seconds;

[012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com