Extraction and separation device for biological pharmacy

A separation device and biopharmaceutical technology, which is applied in the direction of distillation separation, separation method, liquid solution solvent extraction, etc., can solve the problems of increasing the operating cost of biopharmaceuticals, increasing the labor burden of producers, and taking a long time to achieve simple structure, Ease of operation, improved efficiency and the effect of distillation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

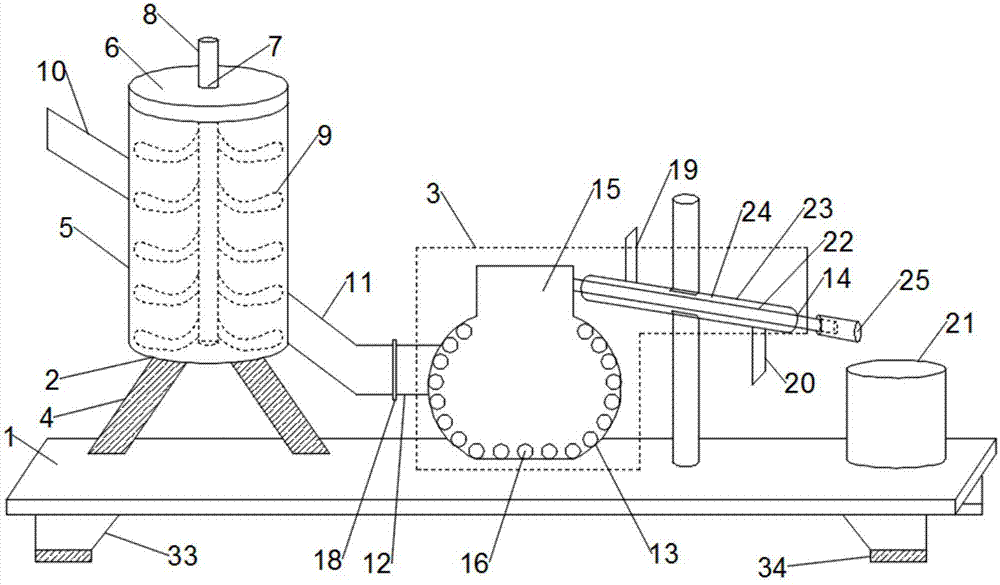

[0023] Such as figure 1 As shown, an extraction and separation device for biopharmaceuticals includes a base 1, the upper surface of the base 1 is provided with an extraction device 2 and a separation device 3, and the extraction device 2 includes a support frame 4 and a cylindrical extraction body 5. The extraction body 5 is set on the top of the support frame 4, the top of the extraction body 5 is provided with a cover 6, the center of the cover 6 is provided with a through hole 7, and the inside of the through hole 7 is provided with a rotating shaft 8 , the top of the rotating shaft 8 is connected to the motor through a belt, the bottom end of the rotating shaft 8 extends through the through hole 7 to the inside of the extraction body 5, and the bottom end of the rotating shaft 8 is infinitely close to the bottom of the extraction body 5 but not in contact, the rotating shaft 8 is evenly provided with a number of stirring pieces 9, the extraction agent inlet 10 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com