Preparation device and process of CeO2 powder by supercritical water system oxidation

A supercritical water and nanotechnology, applied in the fields of nanotechnology, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of poor controllability, low powder preparation efficiency, difficult industrialized production, etc., to achieve good corrosion problems, high production efficiency, low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

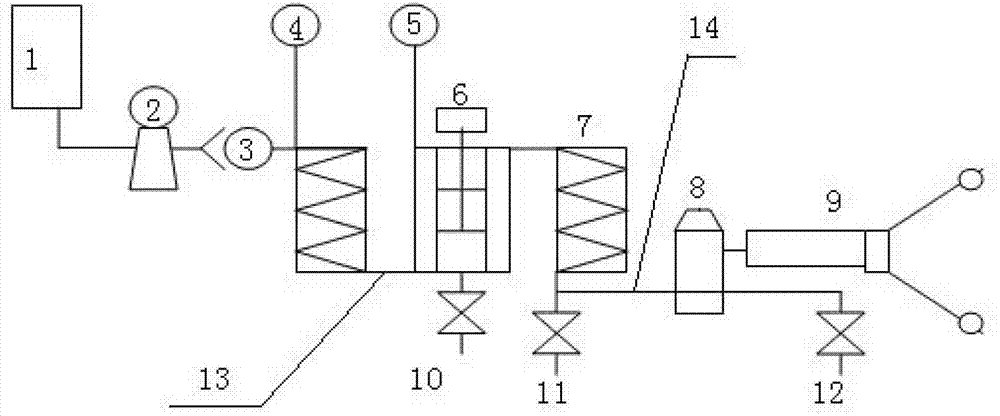

[0025] Such as figure 1 Shown is a kind of supercritical water system oxidation of the present invention prepares nanometer CeO 2 A powder device, which includes a feeding tank 1, a plunger pump 2, a one-way valve 3, a preheater 4, a reaction kettle 5, a magnetic stirrer 6, a condenser 7, a pressure vessel 8, a manual back pressure pump, and 9 Three valves, a first valve 10, a second valve 11, a third valve 12, a first pipeline 13. and a second pipeline 14;

[0026] Wherein, the feeding tank 1 used to hold the raw materials for the supercritical water oxidation reaction is connected with the plunger pump 2 through the one-way pump 3, and the plunger pump 2 is connected with one end of the first pipeline 13, and the first pipeline 13 A preheater 4 for heating the raw materials is arranged on the top, and the raw materials heated by the plunger p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com