Phosphor powder glue processing device for LED lamp production

A technology of LED lights and processing devices, which is applied in mixers with rotating stirring devices, transportation and packaging, chemical/physical processes, etc., can solve problems such as poor uniformity, improve uniformity, ensure mixing uniformity, and avoid The effect of glue solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

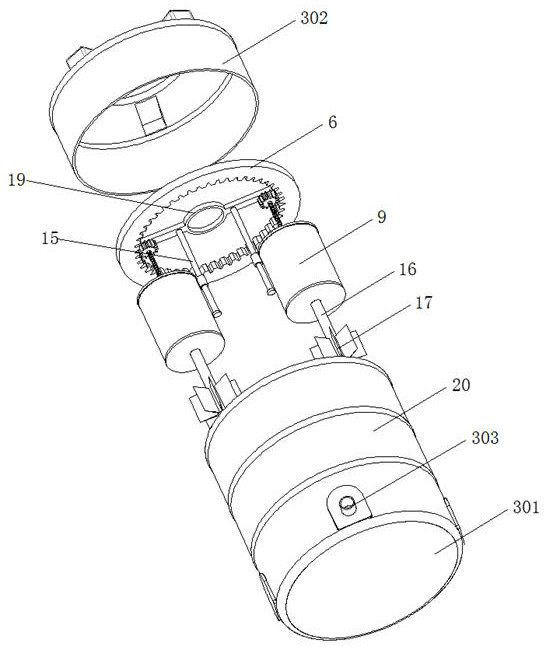

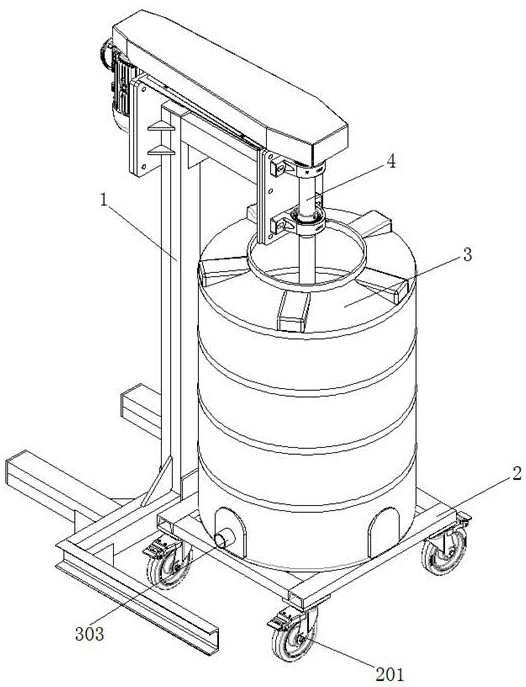

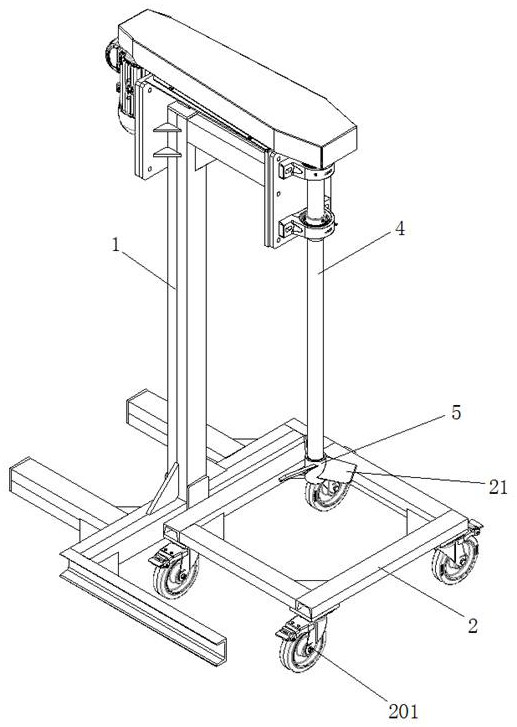

[0032] refer to Figure 1-6 , a fluorescent powder glue processing device for LED lamp production, including a mounting frame 1 and a movable base 2, the top of the movable base 2 is provided with a mixing tank 3, and the mounting frame 1 is provided with a screw extending to the inner cavity of the mixing tank 3 Drive the stirring rod 4, the extension end of the driving stirring rod 4 is detachably connected with the first stirring plate 5 which is offset against the bottom inner wall of the mixing tank 3, the inner wall of the mixing tank 3 is provided with a gear ring 6, and the top of the gear ring 6 is slidingly connected with Mounting plate 7, the drive gear 8 of symmetrical distribution is arranged on the mounting plate 7, and the gear teeth meshing on the drive gear 8 and the ring gear 6, the driving end of the drive gear 8 is connected with quantitative feeding device, and the quantitative feeding device The feeding end is also connected with a stirring assembly; the ...

Embodiment 2

[0036] refer to Figure 1-2 , LED lamp production fluorescent powder glue processing device is basically the same as embodiment 1, further, the outer wall near the bottom of the mixing tank 3 is provided with an electric heating layer 20, to avoid the glue in the tank body 301 from solidifying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com