A jet jet driven blade agitator

A drive type and agitator technology, which is applied in the direction of chemical instruments and methods, dissolution, mixers, etc., can solve the problems of drive motor burnt damage, reduced reliability, root fracture, etc. The effect of improving the power condition and avoiding the blade jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

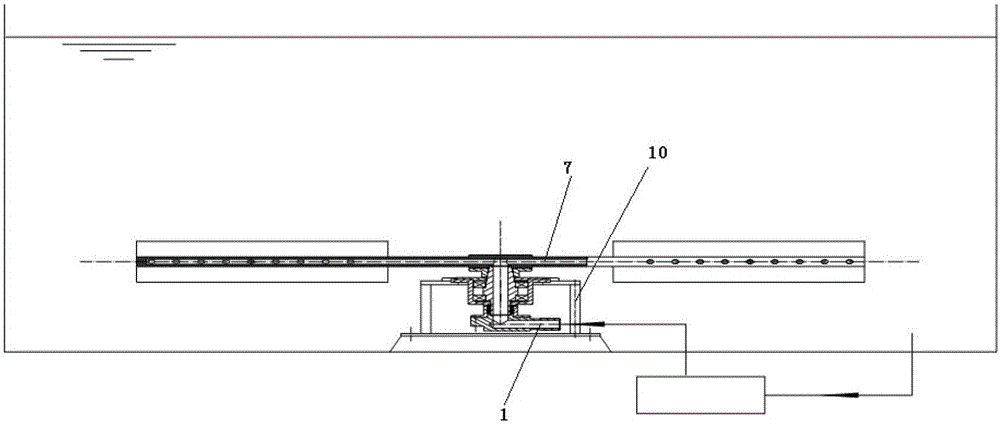

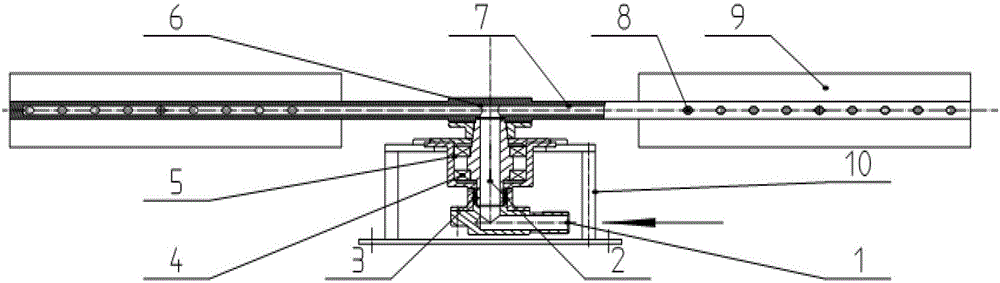

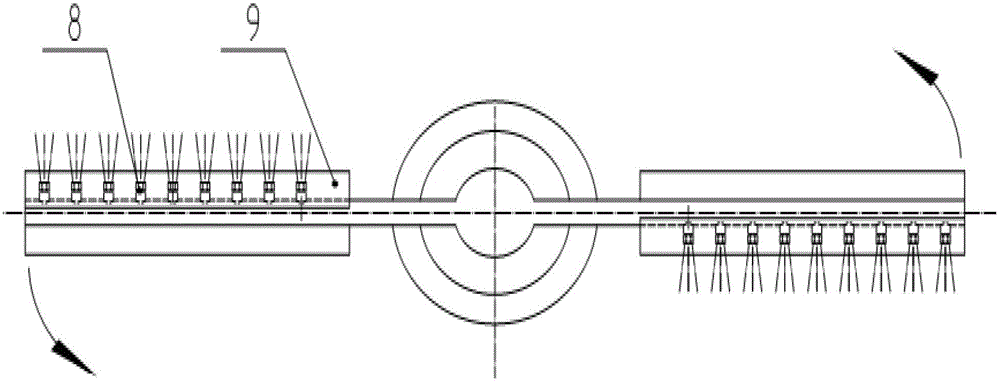

[0013] Referring to the accompanying drawings, a jet jet-driven blade agitator includes a support 10, a bearing seat sleeve 5 is fixedly arranged in the support 10, a rotating hollow shaft 2 is installed in the bearing seat sleeve 5, and the rotating hollow shaft 2 and A bearing 4 and a sealing assembly 3 are arranged between the bearing housings 5, the lower end of the rotating hollow shaft 2 is connected with a horizontal water inlet joint 1, the upper end of the rotating hollow shaft 2 is installed with a water diversion block 6, and the outer side of the water diversion block 6 is connected with a A plurality of circularly arranged spray bars 7, radially distributed nozzles 8 are installed on the spray bars 7, the orientation of the nozzles 8 is consistent with the driving rotation direction, a stirring blade 9 is installed on the spray bars 7, and the orientation of the nozzles 8 is inclined upward, Tilt down.

[0014] The liquid inlet joint 1 communicates with the centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com