Flue gas oxidation and adsorption tower for desulfuration and denitration

A technology for desulfurization, denitrification and adsorption towers, which is applied in gas treatment, air quality improvement, chemical instruments and methods, etc., to achieve the effects of simple structure design, convenient operation and efficient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

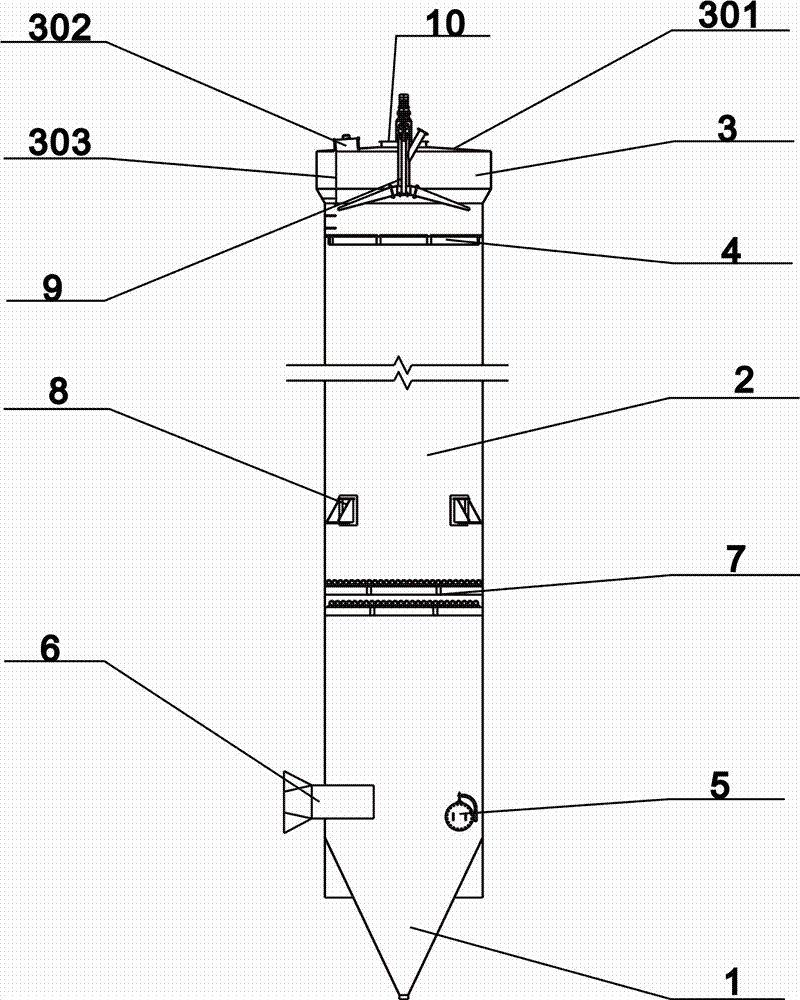

[0022] As shown in the figure, a flue gas oxidation adsorption tower for desulfurization and denitrification includes a collection cylinder 1, a cylinder body 2, and a tower cap 3. The collection cylinder 1 is fixed at the bottom of the cylinder body 2, and the cylinder body 2 is fixed at the collection cylinder. 1, a tower cap 3 is fixed at the upper position of the cylinder body 2, and the diameter of the tower cap 3 is larger than the diameter of the cylinder body 2; The upper left position is fixedly provided with the air inlet 6; the middle position of the cylinder body 2 is fixedly provided with a venturi tube air distribution device 7, and around the outer wall of the upper cylinder body 2 of the venturi tube air distribution device 7, there are evenly arranged ears. Type support 8, the maintenance platform 4 in the tower is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com