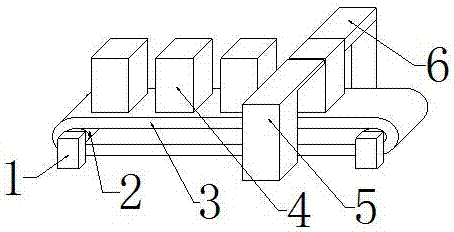

Sponge mat feeding device of limit box assembling equipment

A technology for assembling equipment and sponge pads, which is applied in the field of mechanical equipment, can solve problems such as low work efficiency, easy tilting of sponge pads, and low mechanization of sponge pad feeding, and achieve the effect of improving efficiency and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

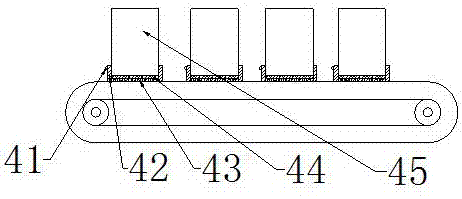

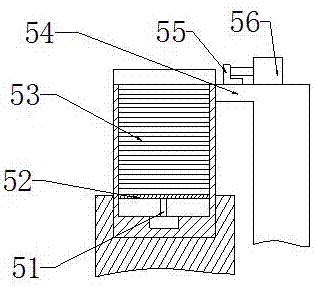

[0024] Specific embodiments: when the staff uses the present invention, the sponge pad body 53 is stacked on the upper end surface of the carrier plate 52 inside the containing box 45, and then the staff places the containing box 45 on the electromagnet 43 between the fixed baffles 42, The staff presses the switch button 41 to connect the power supply between the storage battery and the electromagnet 43, and the electromagnet 43 works closely with the magnet block 44 through the magnetic attraction force, thereby completing the fixing of the containing box 45, and then the staff makes it connect with the rotating shaft The connected motor runs, the motor drives the roller 2 to rotate, the roller 2 rotates to drive the conveyor belt 3 to move, the conveyor belt 3 moves to drive the electromagnet 43 to move, the electromagnet 43 moves to drive the container 45 to move, and the container 45 moves to drive the sponge pad body 53 to move , so that the container 45 is moved to the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com