Lifting system and control method of permanent magnet direct drive electromagnetic hanging beam crane

An electromagnetic hanging beam and permanent magnet direct drive technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of brake wear, inconsistent instantaneous speed, high cost, etc., to prevent slipping hooks and overshoot, stable and precise control , the effect of smooth transition operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

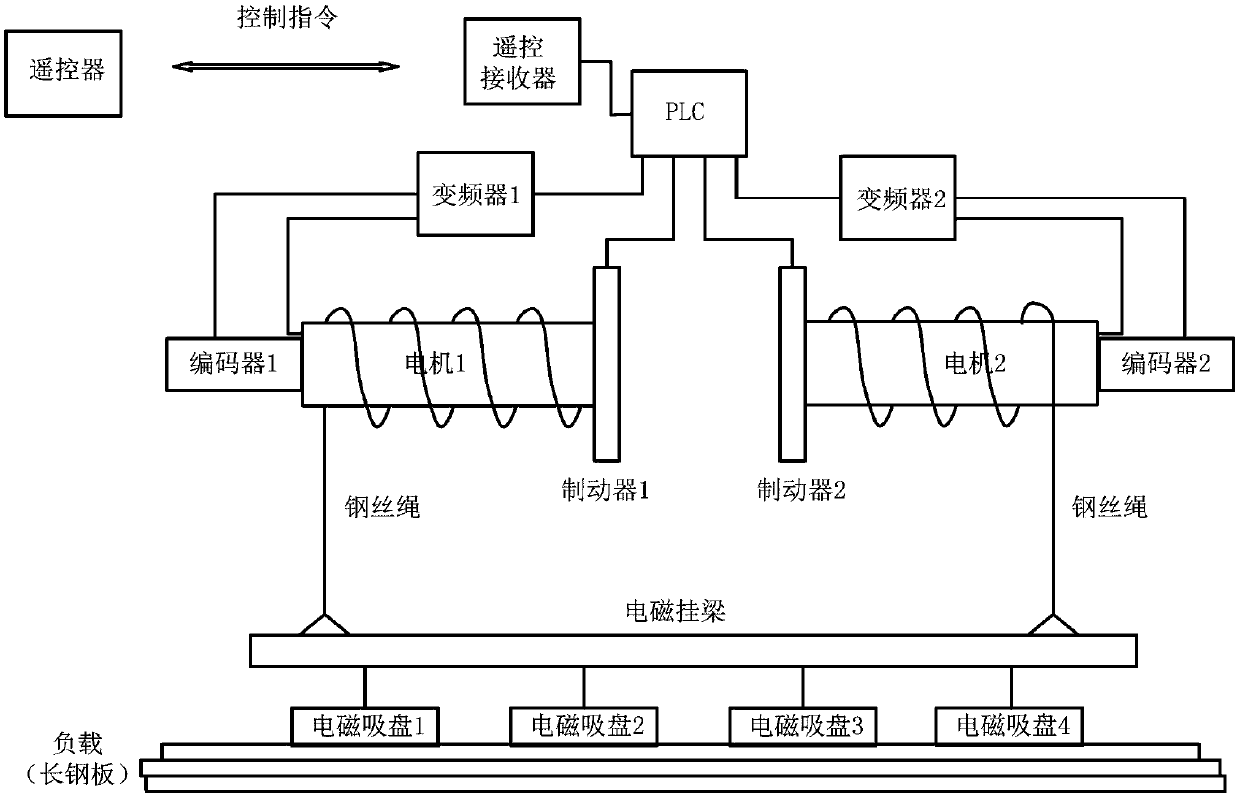

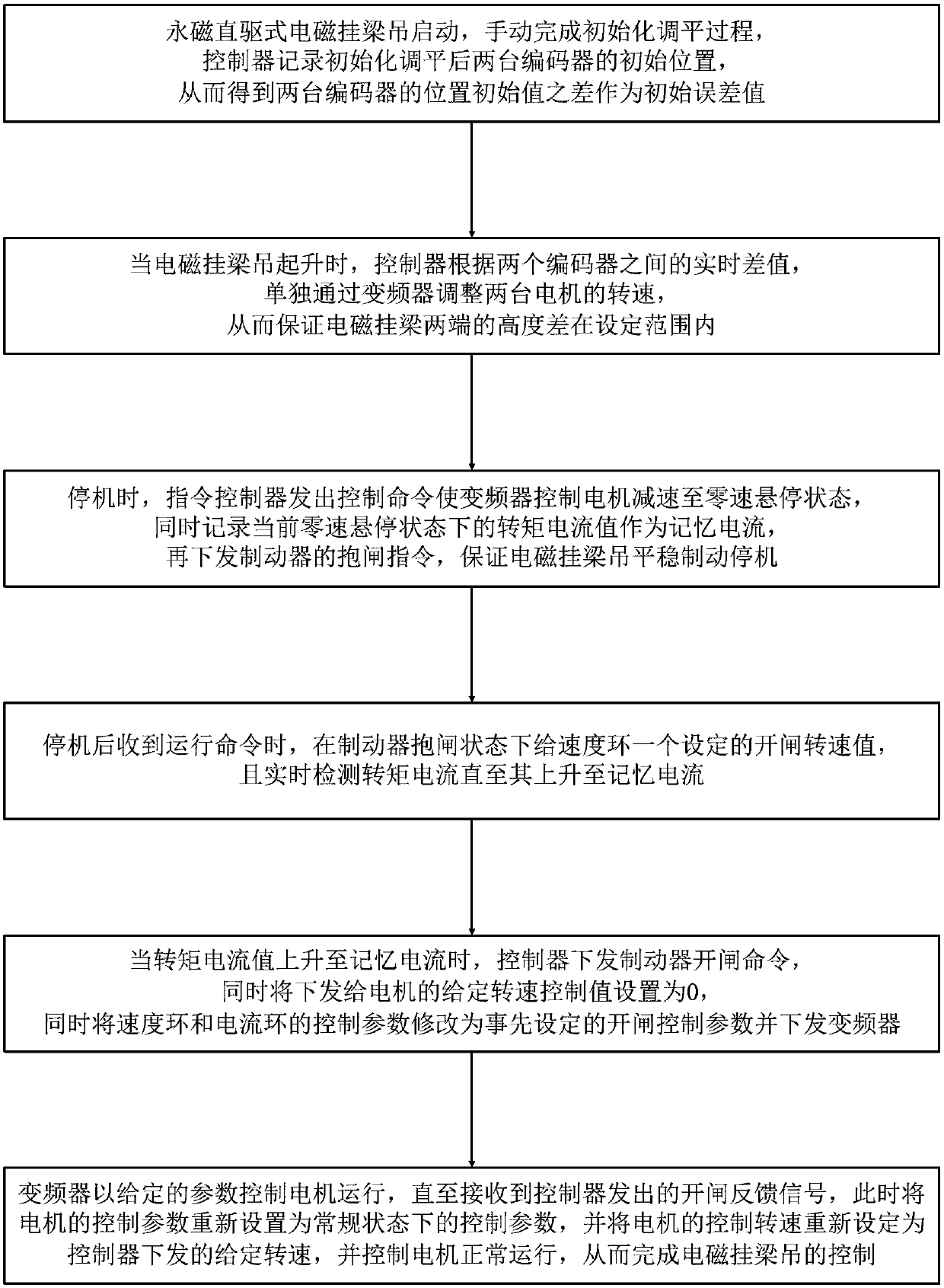

[0033] Such as figure 1 Shown is the functional block diagram of the lifting system of the present invention: the lifting system of the permanent magnet direct drive electromagnetic hanging beam crane provided by the present invention includes a controller, two frequency converters, two direct drive permanent magnet Synchronous motor and its wire rope, two brakes, electromagnetic hanging beam, several electromagnetic suckers, two encoders, remote receiver and remote controller; the controller controls two direct-drive permanent magnet synchronous motors through two frequency converters, and then through Wire ropes, electromagnetic hanging beams and electromagnetic suckers lift or lower heavy objects, and the controller is also connected to the brake to brake the motor by controlling the start and stop of the brake. It also includes: the encoder is connected to the direct drive permanent magnet synchronous motor, It is used to obtain the motor speed and position information of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com