plug flow ao reactor

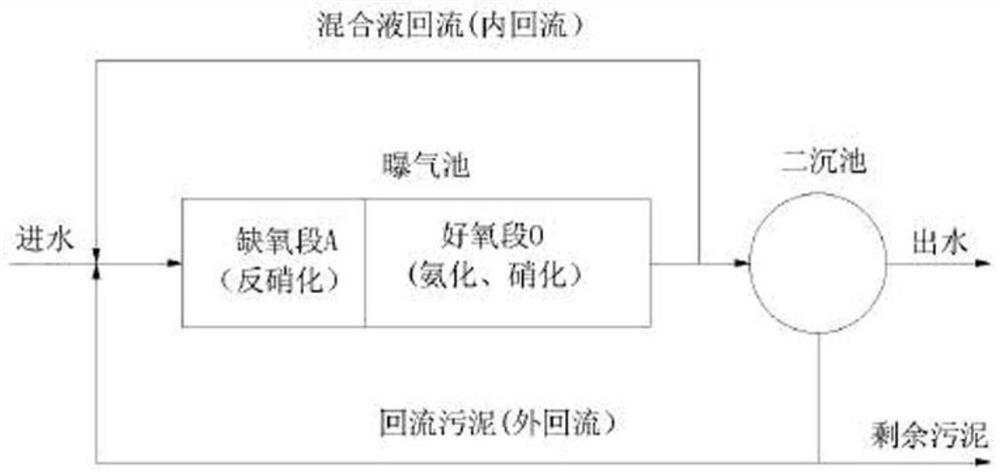

A reactor, plug-flow technology, applied in the field of plug-flow AO reactor, can solve the problems of low processing load, large power consumption of sludge return, and large area of sedimentation tank.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

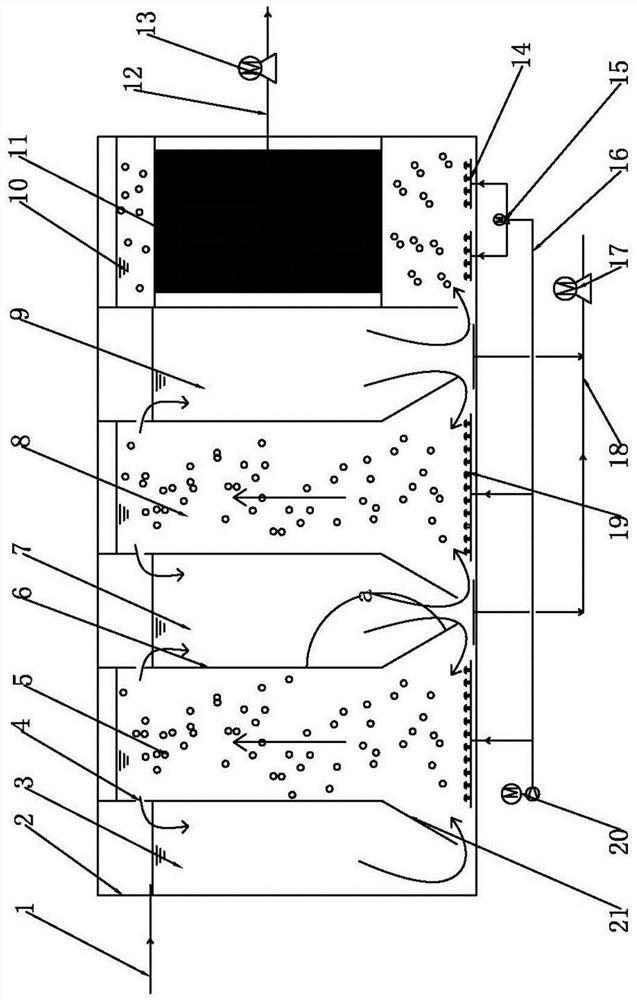

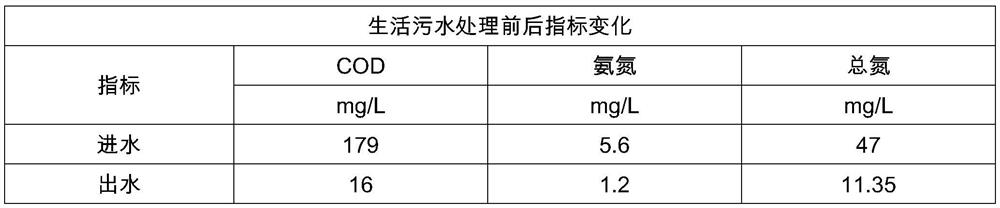

[0028] Such as figure 2 As shown, a plug-flow AO reactor includes a reactor main body 2, and the interior of the reactor main body 2 is divided into several anoxic reaction zones and aerobic reaction zones alternately arranged by baffles from left to right. , the aerobic reaction zone at the end of the reactor is the MBR film aerobic reaction zone 10, the MBR film 11 is set in the MBR film aerobic reaction zone 10, and the upper part of the anoxic reaction zone and the aerobic reaction zone passes through The overflow port 4 arranged on the baffle is connected, the bottom of the anoxic reaction zone and the aerobic reaction zone are connected, and a group of aerobic reaction zone aerators 19 are arranged below each aerobic reaction zone. Described MBR film 11 is provided with water outlet device, and the bottom of described MBR film aerobic reaction zone 10 is provided with two groups of MBR film aerobic reaction zone aerators 14, and described aerobic reaction zone aerator 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com