Automatic sediment division and ejection structure with headwork annular irregular section

A technology with special-shaped cross-sections and structures, which is applied in river regulation and other directions, and can solve the problems of large floor area of grit chambers, strict water flow requirements, and slow filtration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

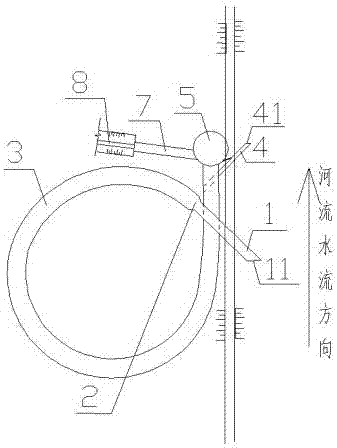

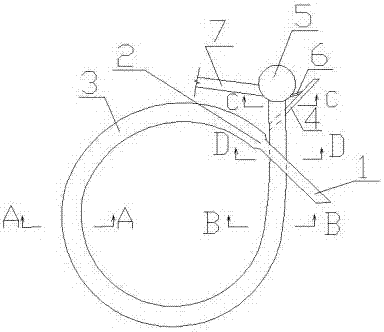

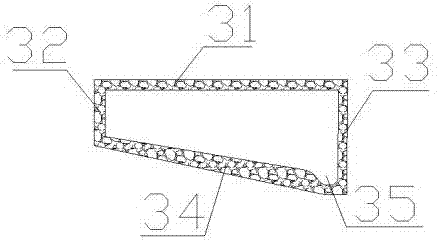

[0016] The present invention will be further described below in conjunction with the drawings.

[0017] Such as Figure 1-7 As shown, the annular shaped cross-section automatic sand discharging structure of the canal head of the present invention is composed of a rectangular section section 1, a water inlet 11, a connecting section 2, a special section section 3, a top plate 31, an outer plate 32, an inner plate 33, and a bottom plate. 34. Sand collecting trough 35, trapezoidal section 36, first section of sand discarding 4, discarding sand port 41, large-diameter vertical tube 5, tube top cover 51, tube bottom plate 52, second section of discarding sand 6, output section 7, diversion channel 8 , The connecting hole 9 is composed of the output section 7 and the diversion canal 8 with the same water passing area, and the water passing area is determined by the irrigation demand design. The water inlet 11 has a 30% larger water passing area than the output section 7; 3 The water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com