Controllable blast or vacuum drying oven

A technology of vacuum drying oven and blast pipe, which is applied in drying solid materials, drying gas arrangement, local stirring dryer, etc. Stable and reliable safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to illustrate the embodiments of the present application or the technical solutions in the prior art more clearly, the embodiments will be briefly introduced below.

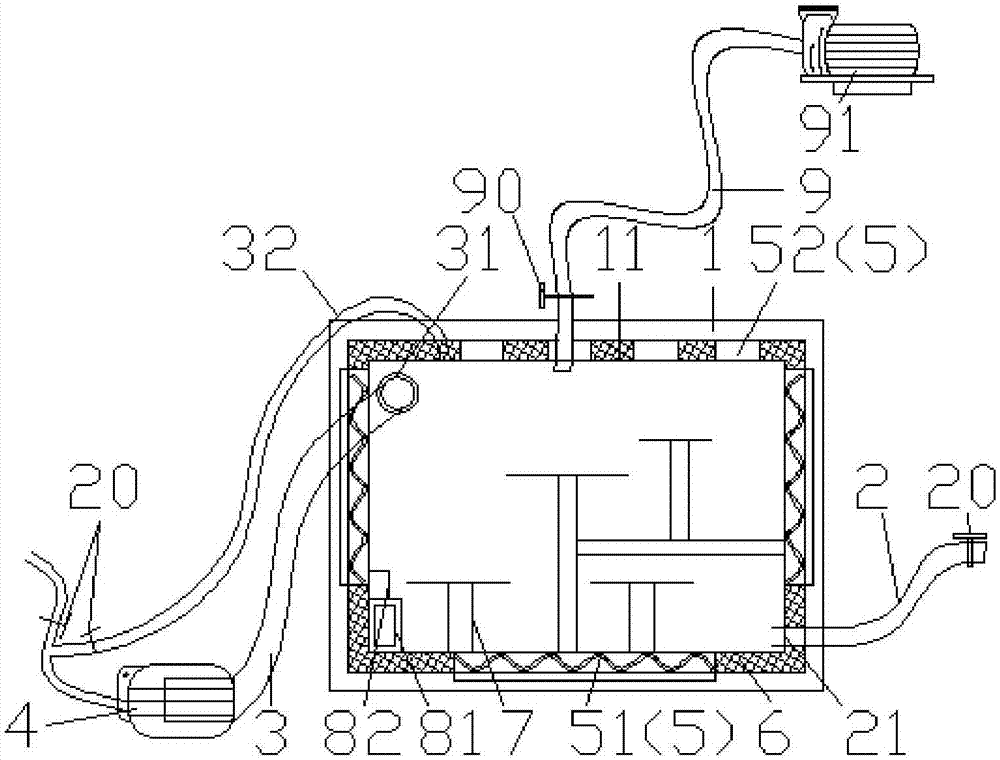

[0018] Such as figure 1 , a controllable blast or vacuum drying box, comprising a box body 1, an air intake pipe 2, a blast pipe 3, a blower fan 4, a vacuum tube 9, and a vacuum pump 91, and the inner layer of the box body 1 is provided with a heating device 5, heat preservation Wall 6, the heat preservation wall 6 is distributed around the heating device 5 and the inner wall surface 11 of the box body 1, the heating device 5 includes an electric heating device 51 and an infrared radiation device 52, and the infrared rays radiated by the infrared radiation device 52 are far infrared rays;

[0019] The air inlet pipe 2 and the blast pipe 3 are respectively connected with the air inlet 21 and the air outlet 31 which are opened in the box body 1 and pass through the inner wall of the box body 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com