Asymmetric permanent magnet auxiliary synchronous reluctance motor and design method for improving torque performance

A technology for assisting synchronous and reluctance motors. It is applied in the direction of magnetic circuit rotating parts, magnetic circuits, and electric components. Effects of Torque Ripple, Weakening and Permanent Magnet Torque Ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

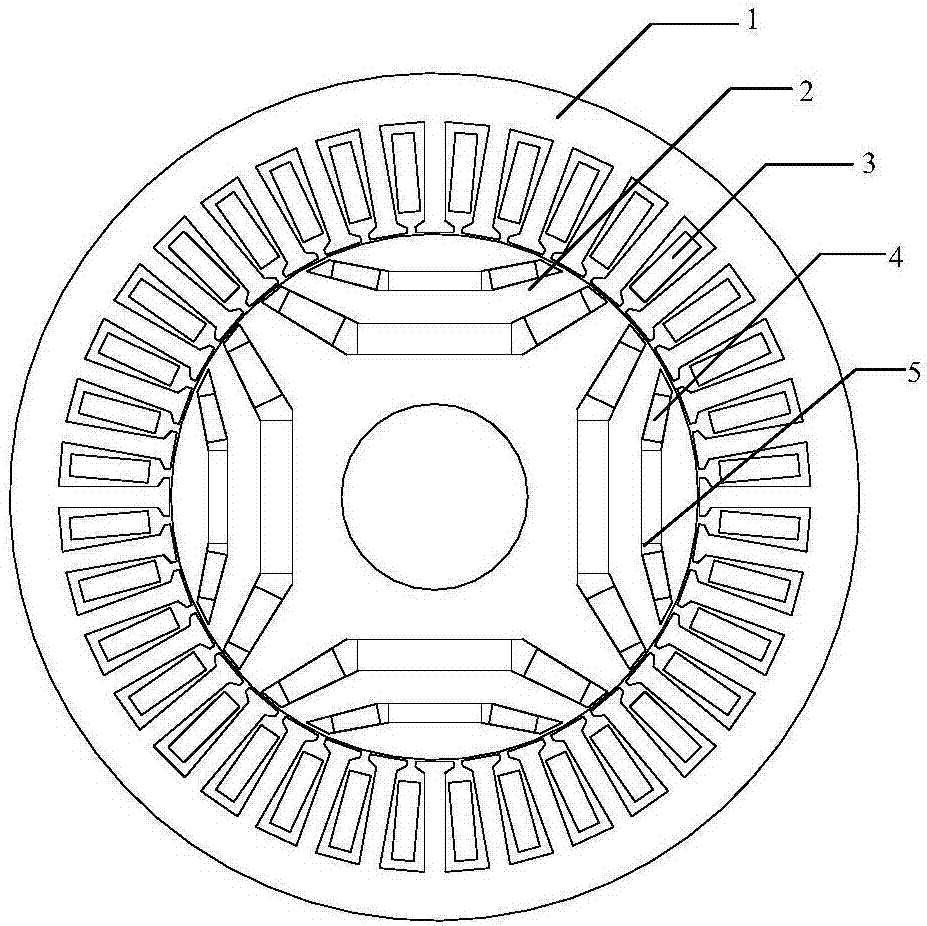

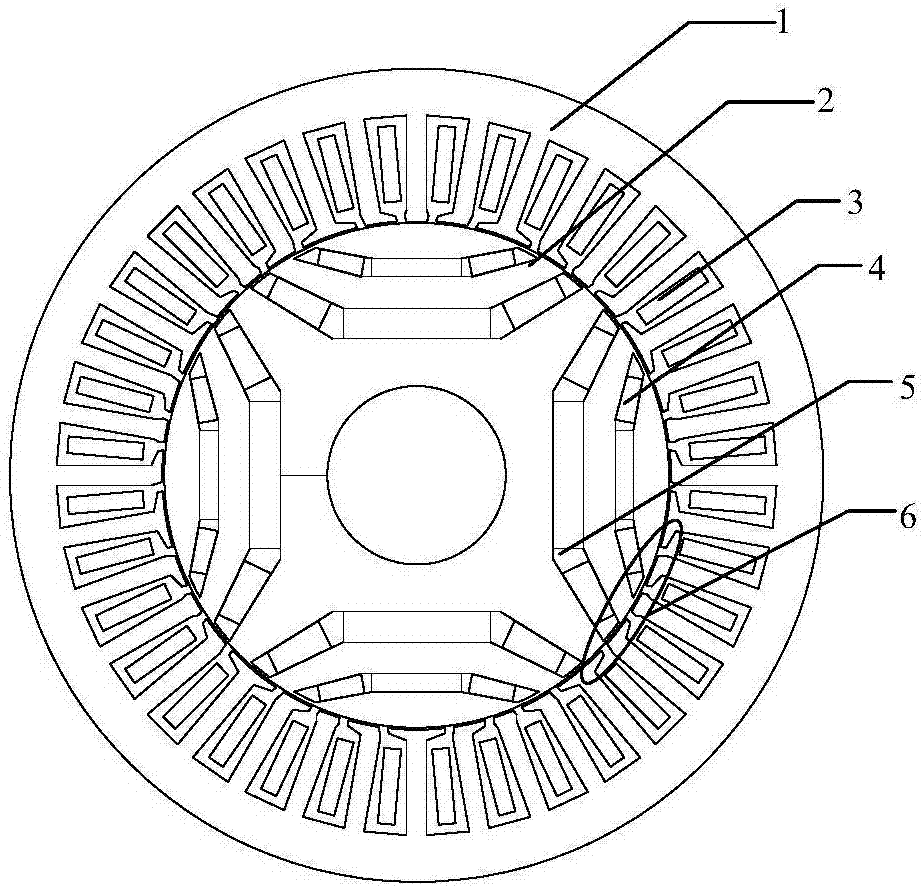

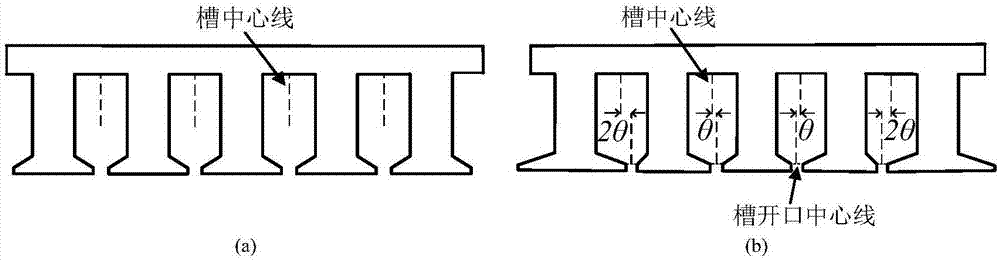

[0037] Such as figure 2 As shown, the invention discloses an asymmetrical permanent magnet assisted synchronous reluctance motor and a design method for obtaining optimal torque performance. figure 1 It is an existing permanent magnet assisted synchronous reluctance motor. Such as figure 1 The permanent magnet assisted synchronous reluctance motor includes a stator 1 and a rotor 2; the stator includes 36 slots and armature windings 3 embedded in the slots; the rotor includes a rotor core, 24 permanent magnets and 4 sets of magnetic barriers ; Each group of magnetic barriers is a 2-layer U-shaped structure. The present invention regards it as the existing motor, and on this basis, the slot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com