Permanent magnetism eddy current shaft coupling

A permanent magnet eddy current and shaft coupling technology, which is applied in the direction of electrical components, electromechanical devices, electromechanical transmission devices, etc., can solve the problem of less heat generation, and achieve the effects of less heat generation, low cleaning frequency and stable torque transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments according to the present invention will be described in detail below with reference to the accompanying drawings.

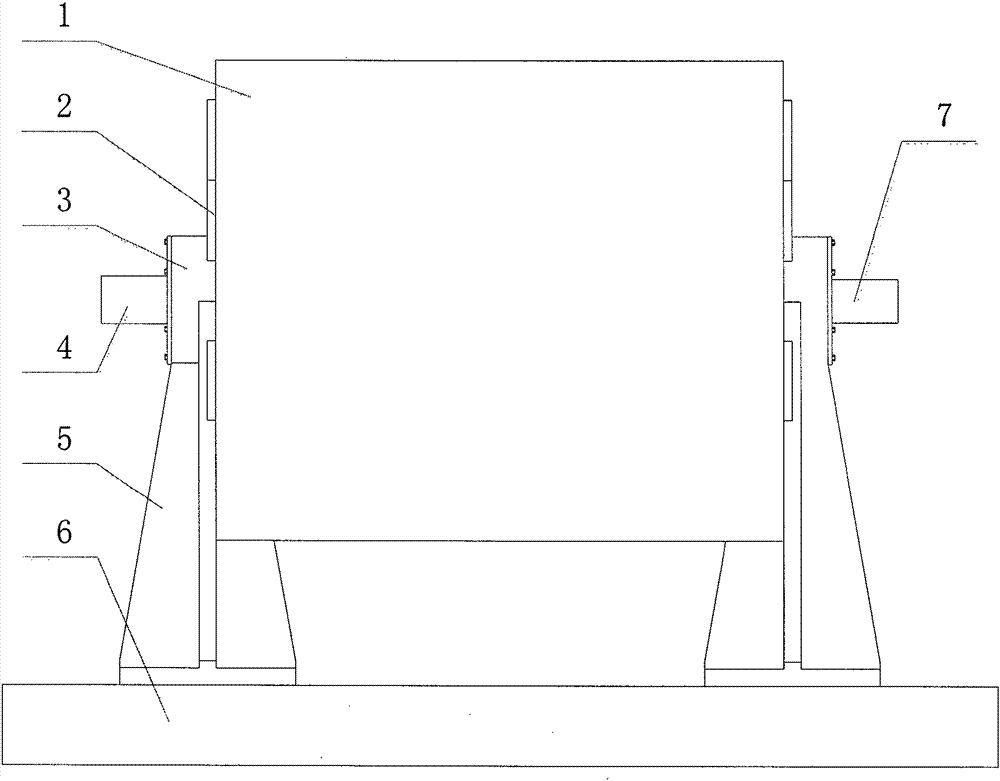

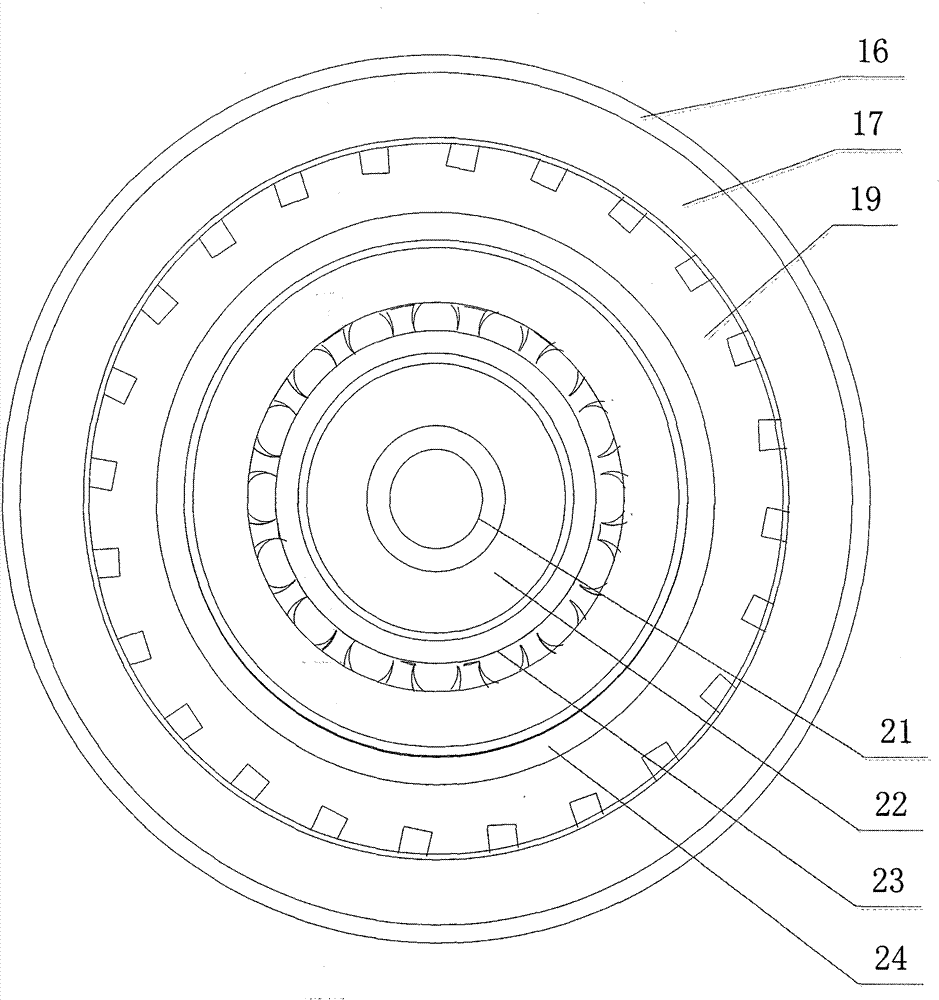

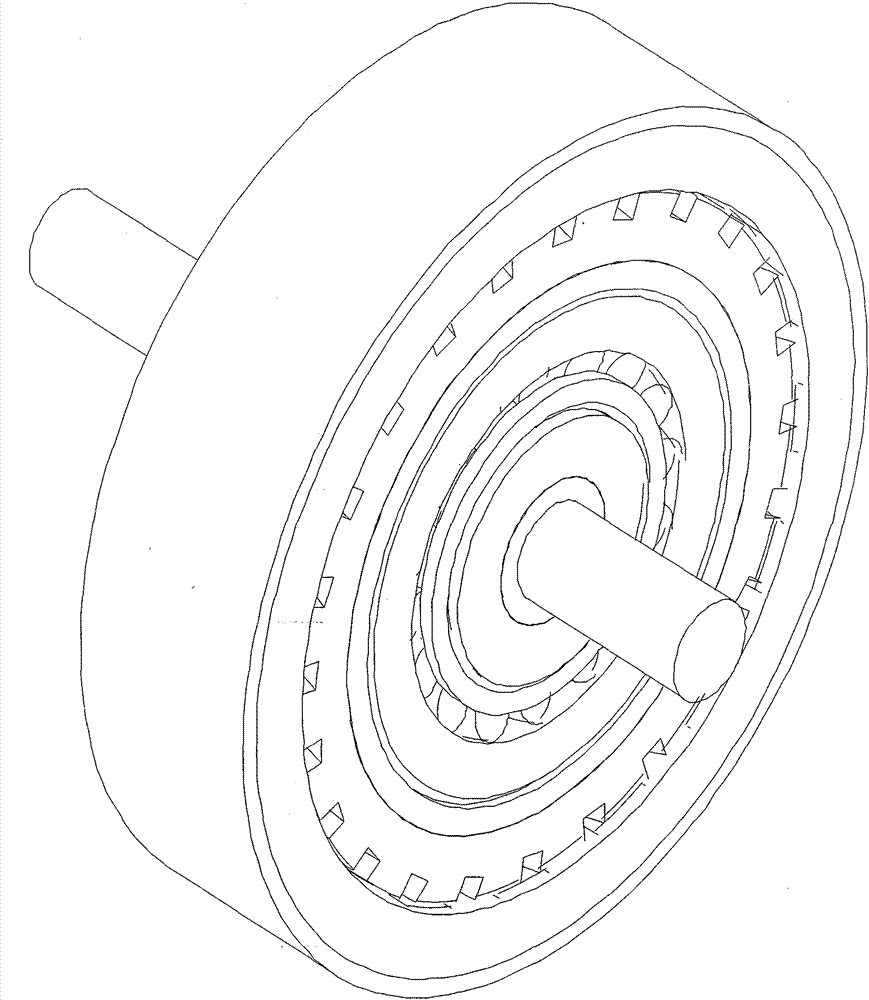

[0032] As shown in the drawings, the permanent magnet eddy current coupling includes: including: active mechanism, driven mechanism, moving mechanism and supporting mechanism, etc.; active mechanism, including active rotor 17, permanent magnet 18, shielding bushing 16, etc. The permanent magnet 18 is wedge-shaped embedded in the active rotor 17, so that the permanent magnet 18 cooperates more firmly with the active rotor 17 during the rotation of the active rotor 17, effectively reducing the vibration and noise caused by the installation gap; the shielding sleeve 16 is located on the outside of the active rotor 17 and moves together with the active rotor 17. The active rotor 17 is made of non-magnetic material, and the shielding lining 16 is made of magnetic material to optimize the thickness of the active rotor, that is, to maximize the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com