Extraction treatment device and method of soyabean protein

A processing device and soybean protein technology are applied in the field of soybean protein extraction and processing devices, which can solve the problems of extensive management, unfavorable soybean protein quality, and insufficient refinement of the technological process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

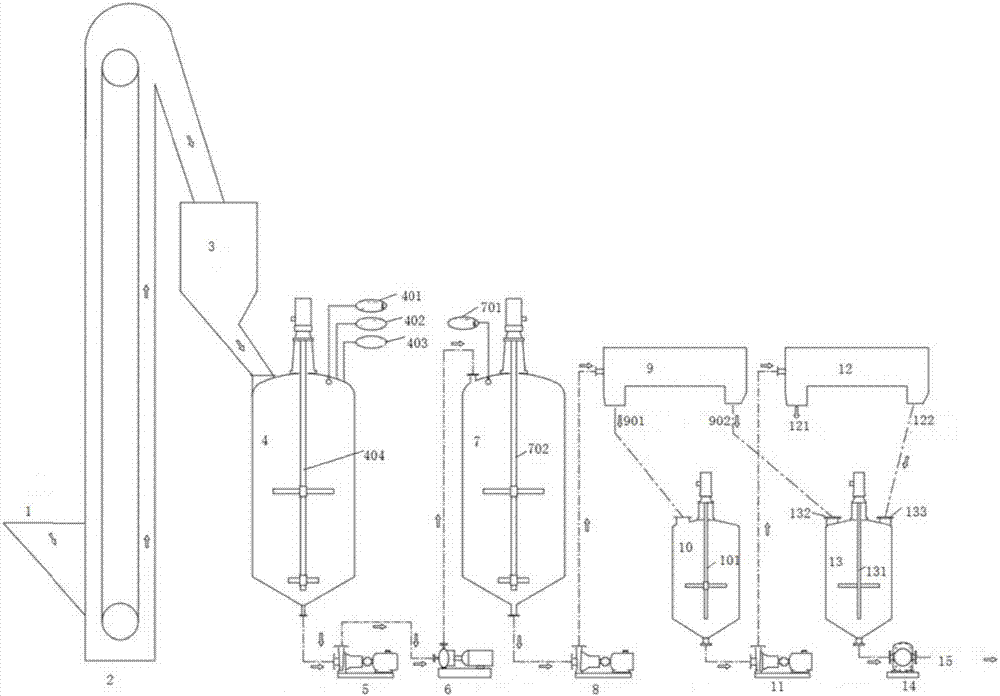

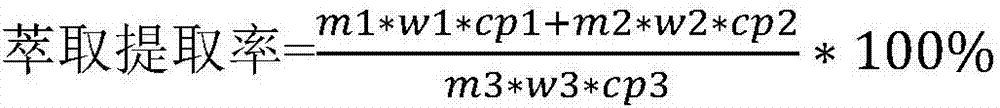

Method used

Image

Examples

Embodiment 1

[0067] (1) One-time extraction: mix low-temperature defatted soybean meal and water at a ratio of 1:10, the water temperature is 30±2°C, and the feed liquid is ground with equipment such as pipeline emulsification pump or colloid mill, and the particle size is 80 mesh through 85±2%. Stir and extract for 45±5min, stirring speed 60±5r / min;

[0068] (2) Primary centrifugal separation: after the primary extraction is completed, the extract is centrifuged with a centrifuge, the solid phase 1 enters the secondary extraction process, and the liquid phase 1 enters the acid precipitation process;

[0069] (3) Secondary extraction: add the solid phase 1 after the primary extraction to dilute acid solution with 8 times the amount of soybean meal for water dissolving and rinsing, and adjust the pH to 1.0. The mesh sieve passes 90±2%, the extraction time is 30±5min, and the stirring speed is 65r / min. Among them, the dilute acid solution is prepared in advance, the concentration of water a...

Embodiment 2

[0073] (1) One-time extraction: mix low-temperature defatted soybean meal with water at a ratio of 1:12, the water temperature is 30±2°C, the feed liquid is ground with pipeline emulsification pump or colloid mill and other equipment, and the particle size is 80 mesh through 85±2%. Stir and extract for 45±5min, stirring speed 60±5r / min;

[0074] (2) Primary centrifugal separation: after the primary extraction is completed, the extract is centrifuged with a centrifuge, the solid phase 1 enters the secondary extraction process, and the liquid phase 1 enters the acid precipitation process;

[0075] (3) Secondary extraction: the solid phase 1 after primary extraction is added to dilute acid solution with 7 times the amount of soybean meal for water dissolving and rinsing, and the pH is adjusted to 1.0. The 80-mesh sieve passes 90±2%, the extraction time is 30±5min, and the stirring speed is 65r / min. Among them, the dilute acid solution is prepared in advance, the concentration of...

Embodiment 3

[0079] (1) One-time extraction: mix low-temperature defatted soybean meal with water at a ratio of 1:12, the water temperature is 35±2°C, the feed liquid is ground with pipeline emulsification pump or colloid mill and other equipment, and the particle size is 80 mesh through 87±2%. Stir and extract for 50±5min, stirring speed 60r / min;

[0080] (2) Primary centrifugal separation: after the primary extraction is completed, the extract is centrifuged with a centrifuge, the solid phase 1 enters the secondary extraction process, and the liquid phase 1 enters the acid precipitation process;

[0081] (3) Secondary extraction: the solid phase 1 after the primary extraction is added to dilute acid solution with 6 times the amount of soybean meal for water dissolution and rinsing, and the pH is adjusted to 2.0±0.3. The feed liquid is ground with equipment such as pipeline emulsification pump or colloid mill, Particle size 80 mesh sieve passes 90±2%, extraction time is 30±5min, stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com