Fabric dyeing method and yarn dyed fabric

A technology for fabric dyeing and dyed fabric, applied in the field of fabric dyeing, can solve the problems of complex process and insignificant effect, and achieve the effect of simple and easy process, improving hydrophilicity and saving water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

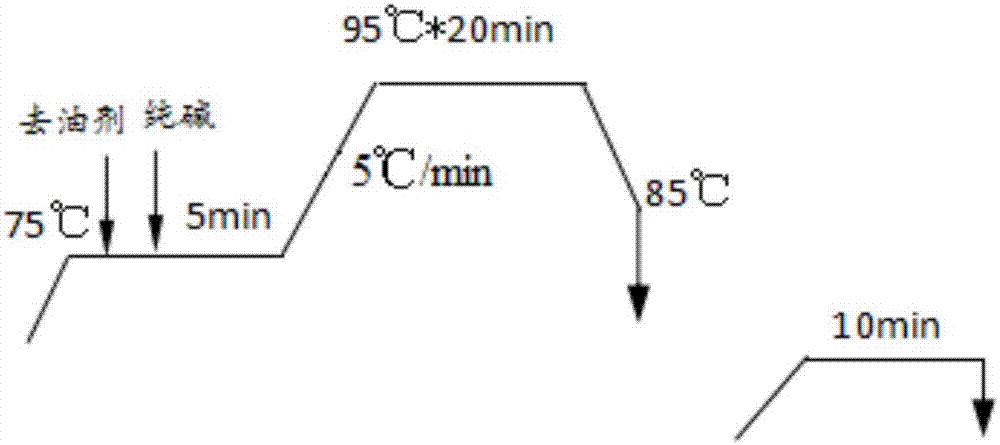

[0051] 1) Before dyeing, according to figure 1 The schematic diagram of the vat washing process curve is shown, the bath ratio is controlled to 1:8, and the degreaser and soda ash are added to the main tank from the auxiliary vat according to the cleaning solution containing 0.5g / L of degreaser and 0.5g / L of soda ash. After the vat, quickly raise the temperature to 72°C and keep it warm for 5 minutes, then raise the temperature to 90°C at a heating rate of 2°C / min, keep it warm for 25 minutes, then cool down to 80°C to drain the liquid, then wash the dyeing vat with clean water for 10 minutes once, and drain the liquid.

[0052] 2) Put the knitted fabric in a clean dye vat for pre-treatment scouring, dyeing and post-treatment soaping to obtain semi-finished dyed fabric.

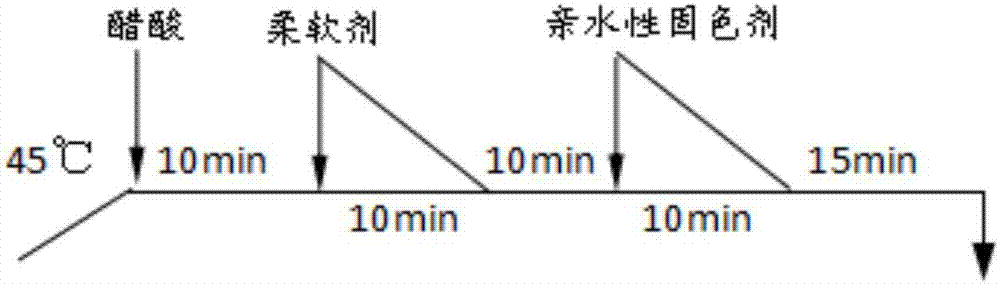

[0053] 3) After soaping, follow figure 2 The schematic diagram of the over-softening and color-fixing process curve is shown, the bath ratio is controlled at 1:6, and the required acetic acid is added from ...

Embodiment 2

[0056] 1) Before dyeing, according to figure 1 The schematic diagram of the cleaning process curve shown in the figure shows that the bath ratio is controlled to be 1:9, and the cleaning solution contains 1.2g / L of degreaser and 1.2g / L of soda ash, and the required degreaser and soda ash are added from the auxiliary tank to the main tank After the vat, quickly raise the temperature to 75°C and keep it warm for 5 minutes, then raise the temperature to 95°C at a heating rate of 5°C / min, keep it warm for 20 minutes, then cool down to 85°C to drain the liquid, and then wash the dyeing vat with clean water for 10 minutes, once, and drain the liquid.

[0057] 2) Put the knitted fabric in a clean dye vat for pre-treatment scouring, dyeing and post-treatment soaping to obtain semi-finished dyed fabric.

[0058] 3) After soaping, follow figure 2 The schematic diagram of the over-softening and color-fixing process curve is shown, the bath ratio is controlled to 1:7, and the pH of the ...

Embodiment 3

[0061] 1) Before dyeing, according to figure 1 The schematic diagram of the cleaning process curve shown in the tank, the bath ratio is controlled at 1:10, according to the cleaning solution containing 2g / L of degreaser and 2g / L of soda ash, add the required degreaser and soda ash from the auxiliary tank to the main tank , quickly raise the temperature to 78°C and keep it for 10 minutes, then raise the temperature to 95°C at a heating rate of 5°C / min, keep it for 15 minutes, then cool down to 85°C to drain the liquid, then wash the dyeing vat with water for 10 minutes, once, and drain the liquid.

[0062] 2) Put the knitted fabric in a clean dye vat for pre-treatment scouring, dyeing and post-treatment soaping to obtain semi-finished dyed fabric.

[0063] 3) After soaping, follow figure 2 The schematic diagram of the oversoftening and color fixing process curve is shown, the bath ratio is controlled to 1:8, and the pH of the solution is adjusted to 5-6. First, the required a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com