Heat-insulating board made from foaming cement, production method and wall surface with heat-insulating board

A technology of thermal insulation and foamed cement, which is applied in thermal insulation, insulation improvement, climate change adaptation, etc. It can solve problems affecting the overall shape, impact resistance, and fire prevention, etc., and achieve the effect of convenient production process and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

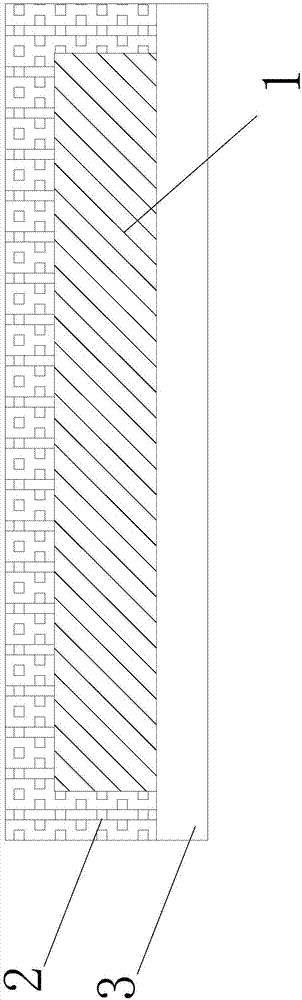

[0020] See figure 1 , The thermal insulation panel of this embodiment includes: a vacuum insulation panel 1 , a foamed cement layer 2 covering the outer surface and surrounding end surfaces of the vacuum insulation panel 1 , and a decorative panel 3 attached to the inner surface of the vacuum insulation panel 1 . The inner surface of the vacuum insulation panel 1 is attached to the center of a decorative panel 3, the length and width of the decorative panel 3 are respectively larger than the length and width of the vacuum insulation panel 1; the foamed cement layer 2 is foamed on the vacuum insulation panel 1 and the outer surface of the decorative panel 3, and cover the four end surfaces of the vacuum insulation panel 1.

[0021] A glass fiber mesh or glass fiber cloth is laid in the foamed cement layer 2 .

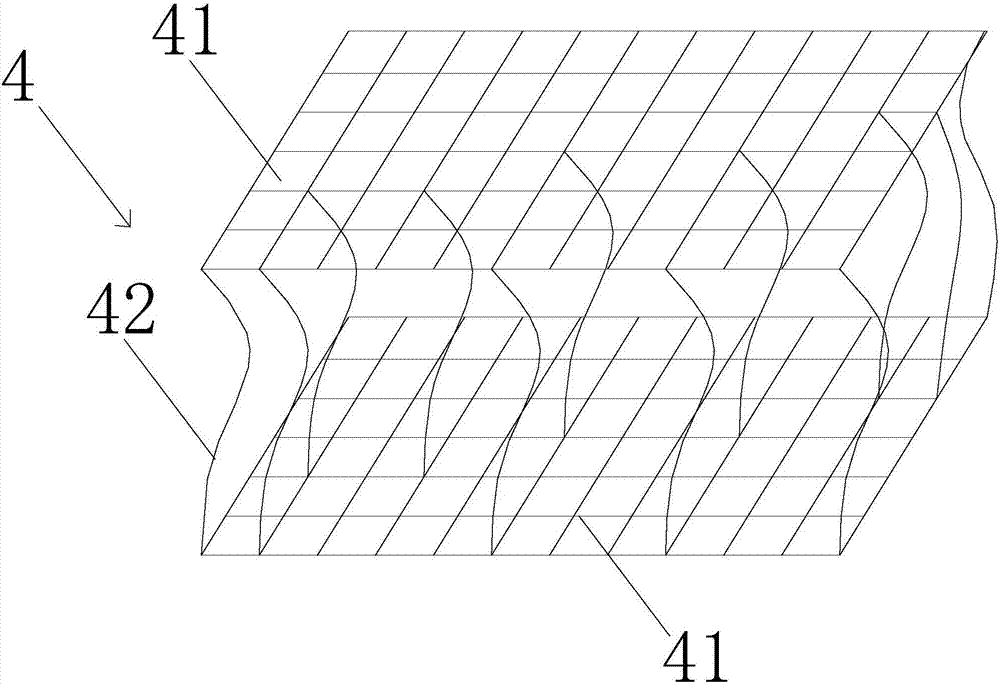

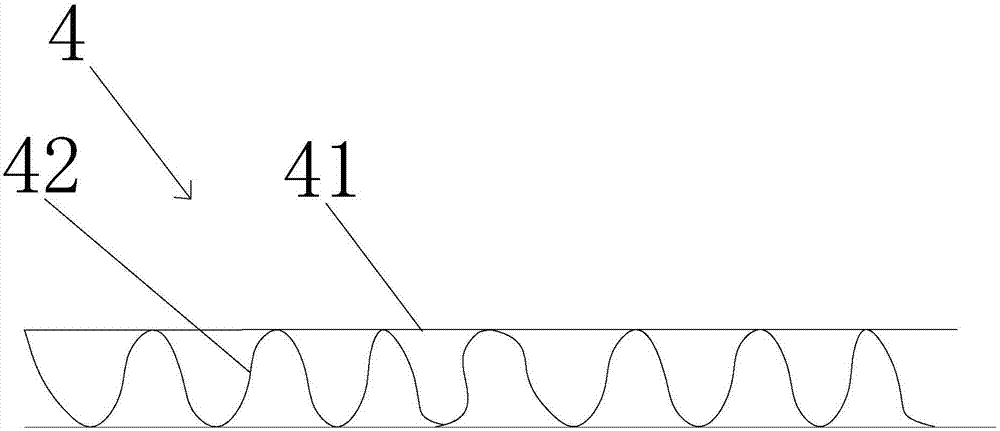

[0022] See Figure 2-3 , the glass fiber mesh or fiberglass cloth has multiple layers and is distributed in parallel between the upper and lower layers. The glass fibe...

Embodiment 2

[0025] The production method of the thermal insulation board described in the above-mentioned embodiment 1, comprising:

[0026] placing the decorative panel horizontally in the mold cavity of the mold having an opening at the top;

[0027] placing the vacuum insulation panel at the center above the decorative panel, and placing at least one frame 4 at the center above the vacuum insulation panel;

[0028] Pour a corresponding volume of foam cement slurry into the mold cavity to close the mold cavity; wait for the slurry to foam and solidify to form.

[0029] The use of the frame makes the whole construction convenient and efficient; there is no need to lay multiple layers of glass fiber mesh or glass fiber cloth layer by layer.

Embodiment 3

[0031] A wall surface, the inner or outer surface of the wall is laid with a plurality of thermal insulation boards described in the above-mentioned embodiment 1 or 2.

[0032] The thermal insulation boards are aligned and arranged to pave the wall to achieve thermal insulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com