Spray dust suppression device along the belt

A technology of spray dust reduction and belt, applied in safety devices, dust prevention, transportation and packaging, etc., can solve the problems of reducing labor intensity and manual operation of operators, and achieve the effect of satisfying dust reduction effect, reducing impact and efficient promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

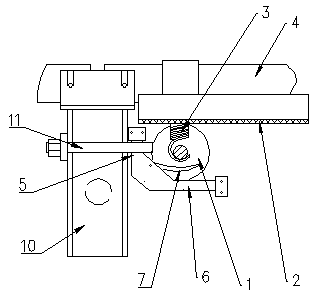

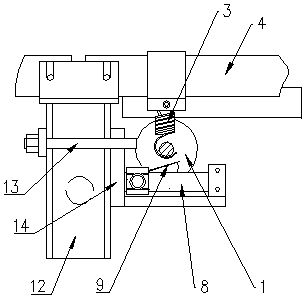

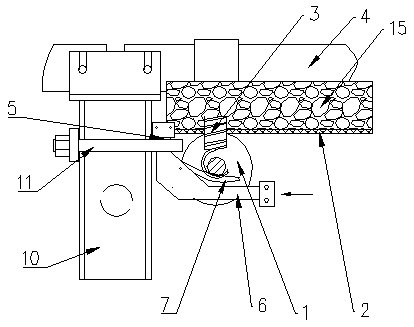

[0017] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the spray dust suppression device along the belt of the present invention comprises a belt idler 1, and the belt idler 1 is arranged along the left and right horizontal directions, and the top of the belt idler 1 is provided with a material conveyor belt 2, and the material conveyor belt 2 is arranged along the front and rear directions, The lower surface of the material conveyor belt 2 is matched with the top of the circumferential surface of the belt idler 1, and the left and right ends of the belt idler 1 are respectively connected with the bottom end of a tension spring 3, and the two tension springs 3 are respectively aligned vertically. Direction setting, the tops of the two tension springs 3 are respectively connected to the frame 4, and the left side below the belt idler 1 is provided with a liquid injection gun, which is connected to the frame 4;

[0018] Described liquid injection gun comprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com