Patents

Literature

47results about How to "Guaranteed dust suppression effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

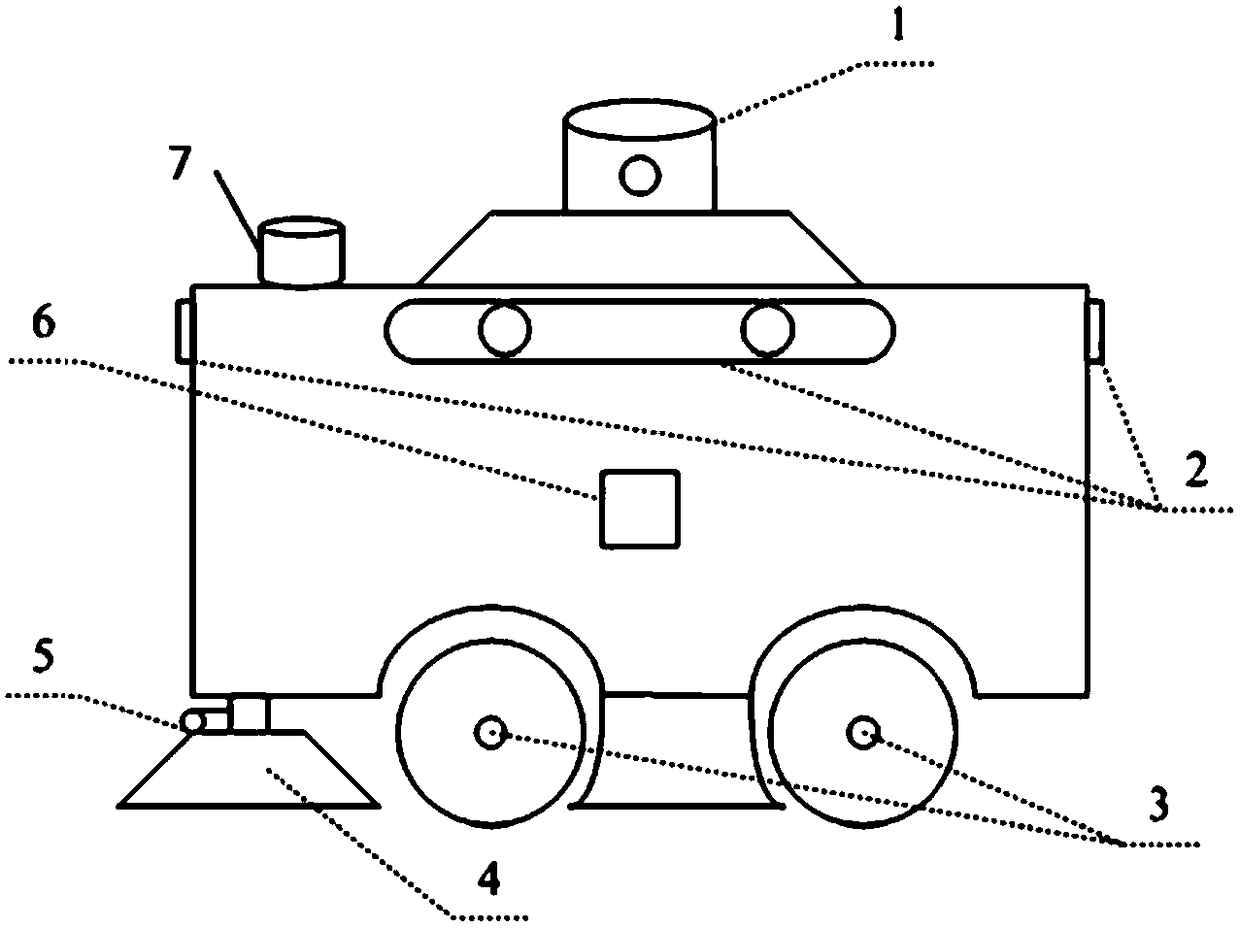

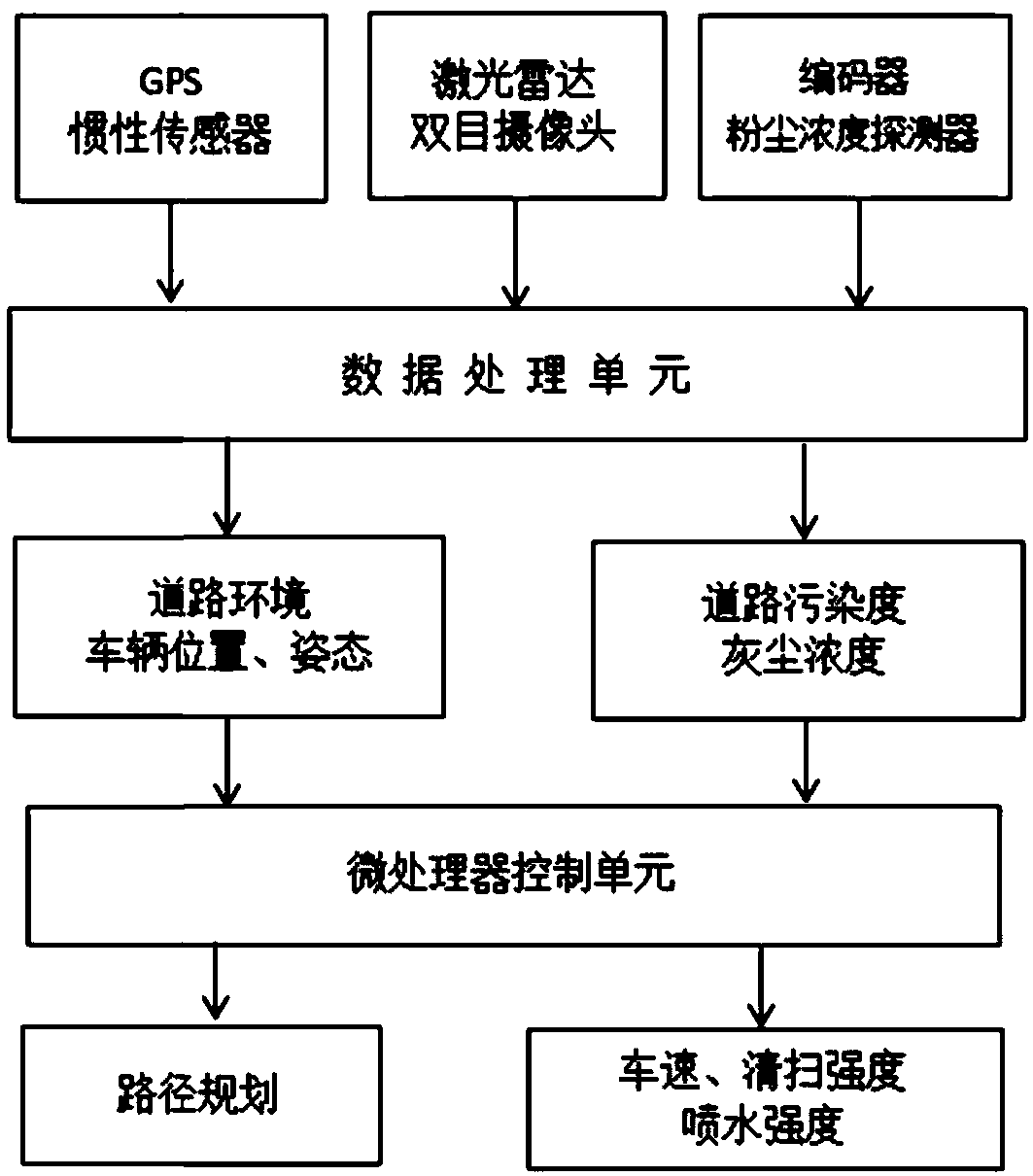

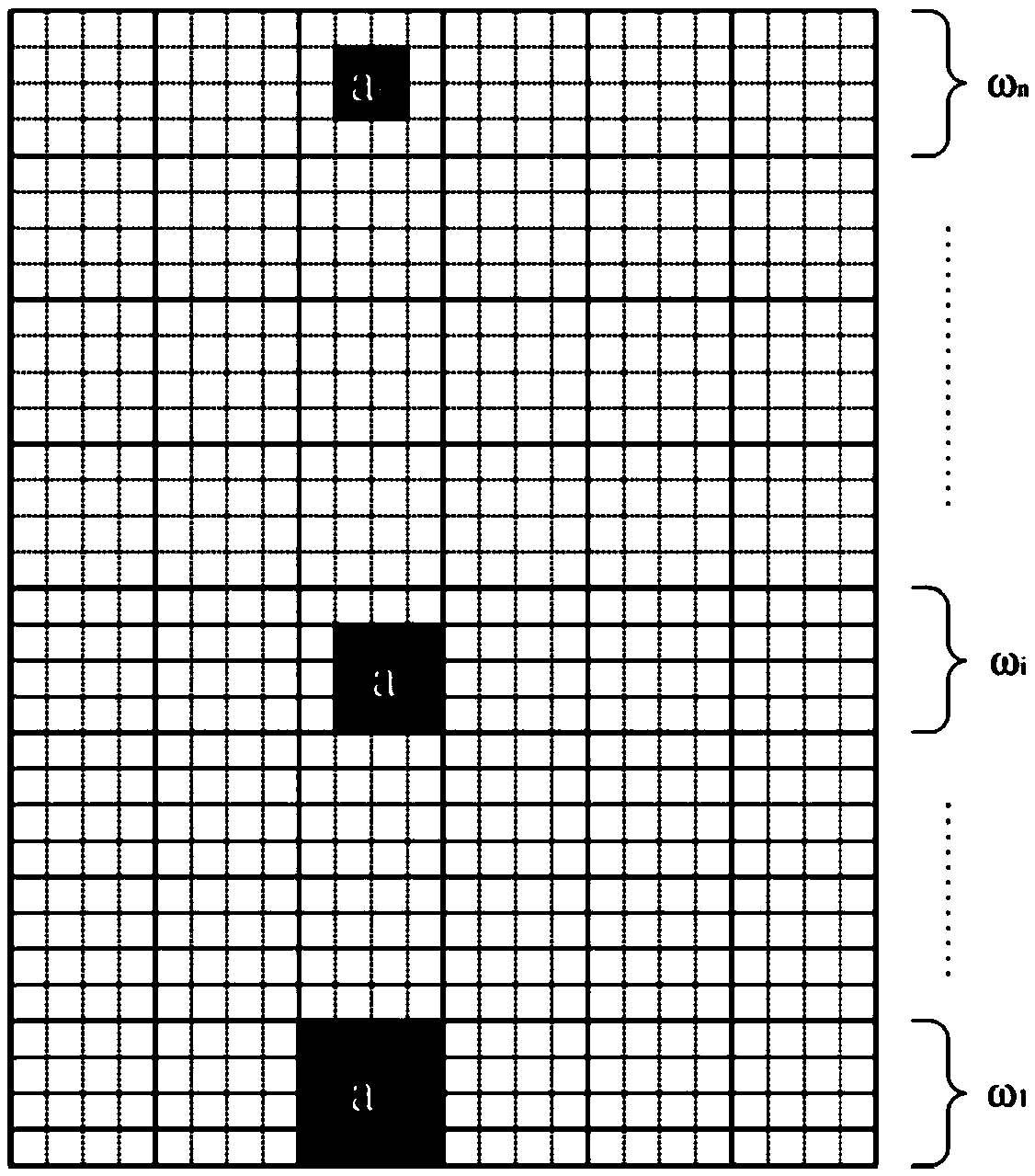

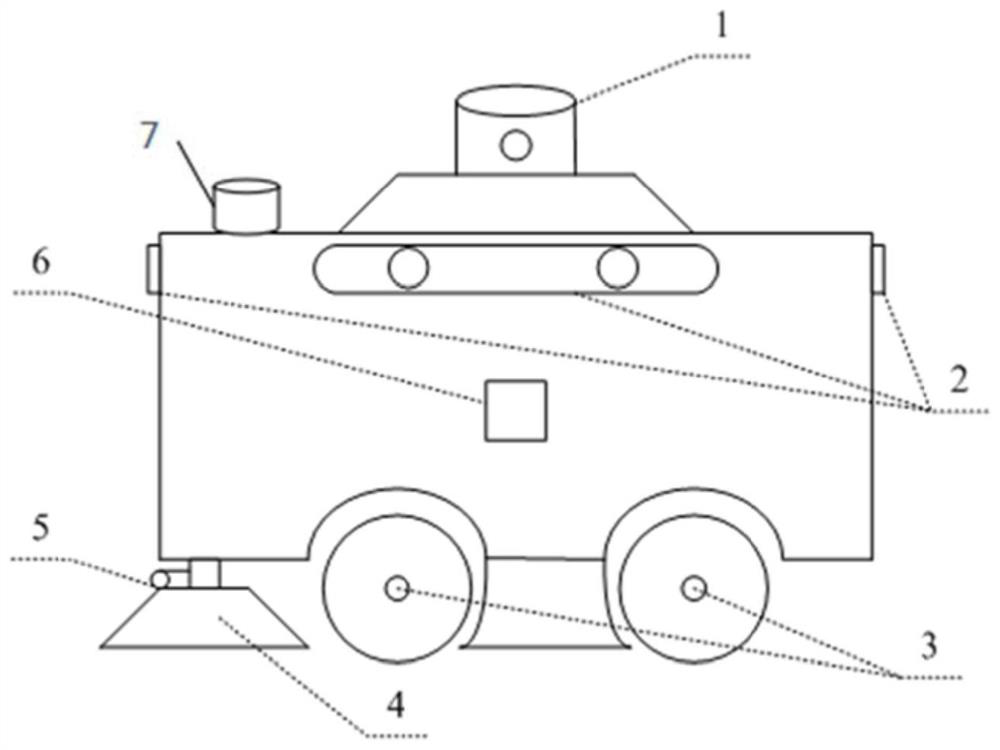

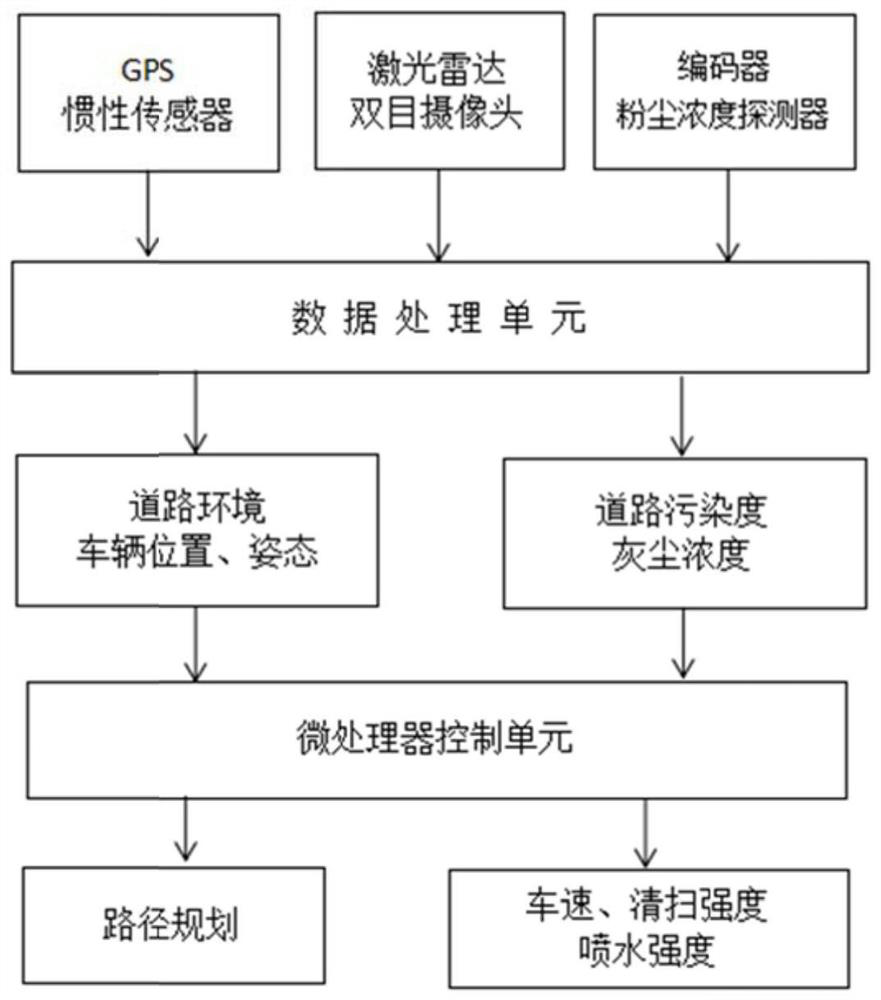

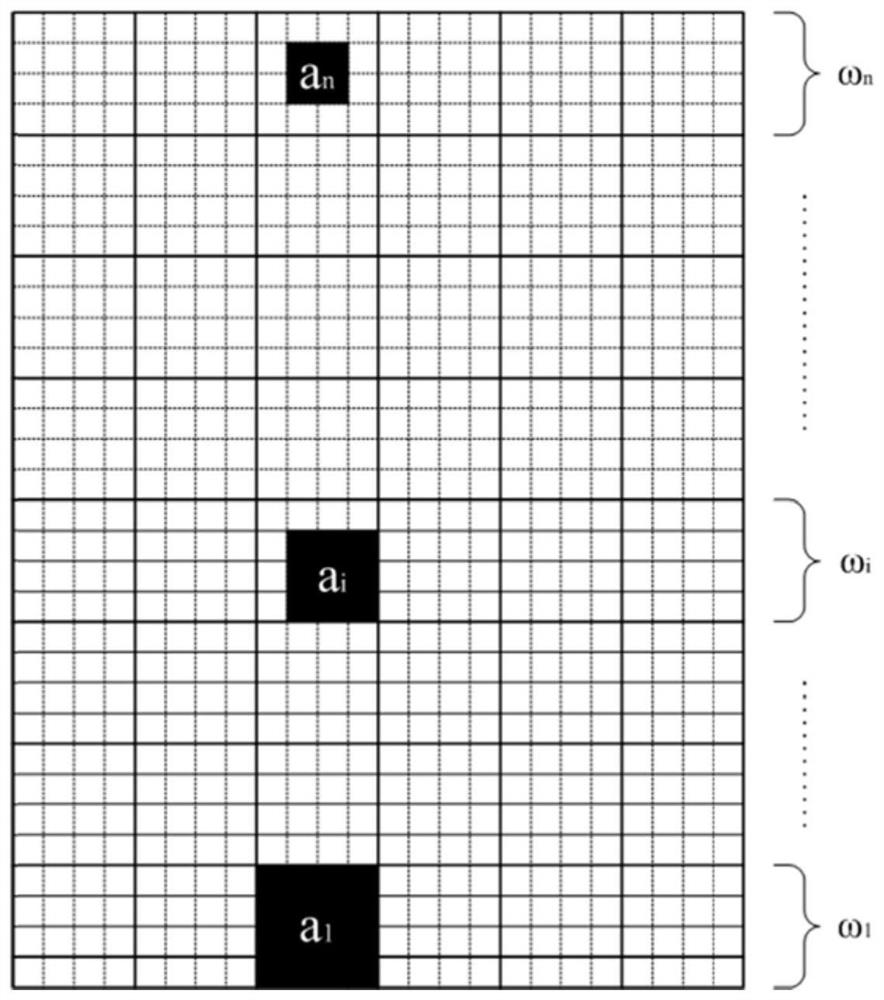

Intelligent road sweeper and a road pollutant identification method and a control method thereof

ActiveCN109024417AGood safety and reliabilityImprove cleaning qualityRoad cleaningPollutantNetwork model

The invention discloses an intelligent road sweeper and a road pollutant identification method and a control method thereof. The road sweeper comprises a road sweeper body, a laser radar, a camera, anencoder, a dust concentration detector, an inertial sensor, a GPS system and a processing controller. A method for identify road pollutants include acquiring RGB images of clean road surface and roadfacilities to be cleaned, convert that acquired RGB images into HSV space, and obtaining a BP neural network model capable of identifying the clean road surface and road facilities; The real-time image information of the road to be cleaned is input to the BP neural network model to identify the pollutants. The method for identifying pollutants such as garbage in the present invention utilizes theHSV feature of a road image, which has a larger information amount of the gray value of the image than that of a single image, and has a better effect for identifying pollutants such as garbage.

Owner:CHANGAN UNIV

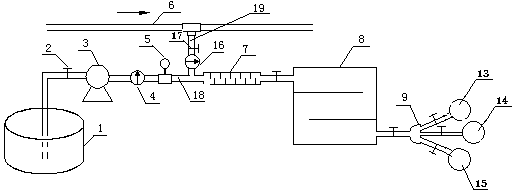

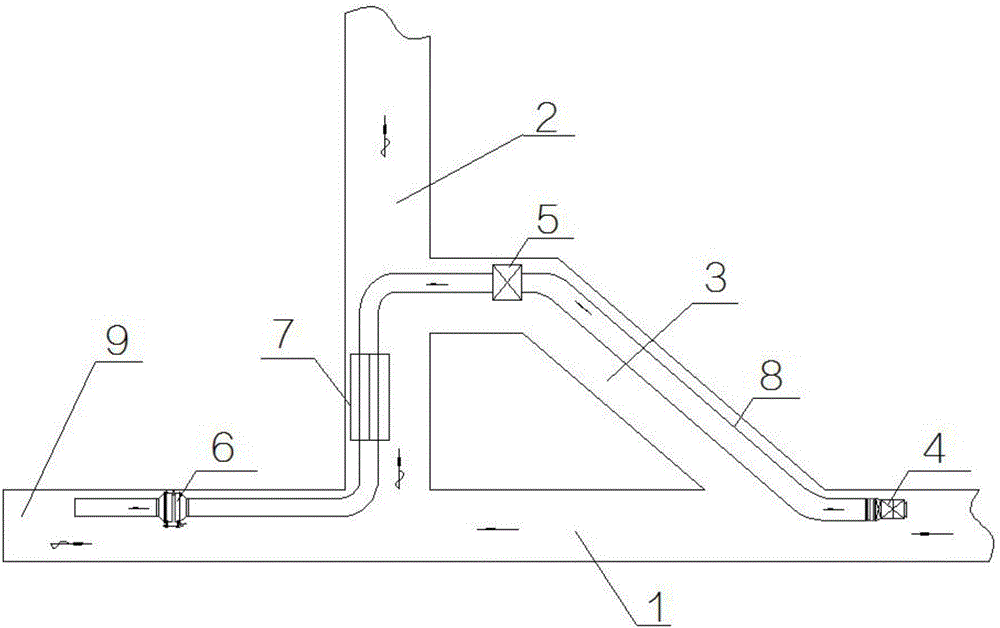

Mining active magnetic water dust-settling method and system

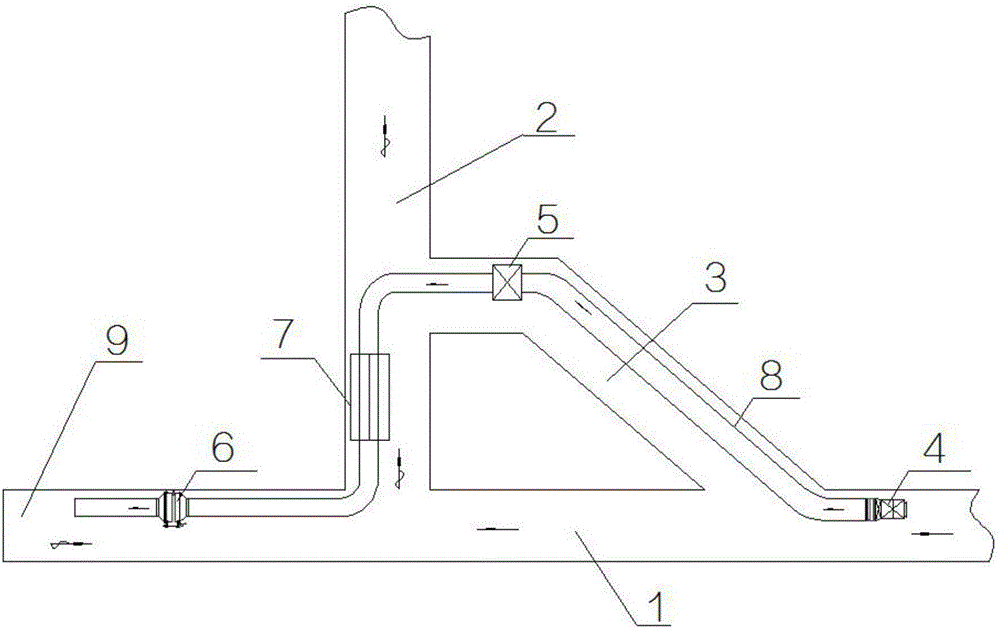

ActiveCN103967488AReduce fogging effectImprove atomization effectDust removalFire preventionActive agentWater flow

The invention discloses a mining active magnetic water dust-settling method and system. The method comprises processes as follows: an active agent suction pipe extracts a surface active agent from an active agent adding barrel, and the surface active agent and water in static pressure water supply pipe are mixed uniformly in a mixer; formed active water flows in a Z-shaped magnetic channel of a magnetizer and is magnetized; and magnetized active magnetic water is transported to a coal cutter spray system, a combined mining supporting spray system and a transferring point spray system for spray dust settlement. The system comprises the active agent adding barrel, the static pressure water supply pipe, the mixer, the magnetizer, the coal cutter spray system, the combined mining supporting spray system, the transferring point spray system, the active agent suction pipe, a branch pipe, a valve I, a pneumatic liquid driving pump, a flowmeter I, a check valve, a valve II and a flowmeter II, wherein multiple groups of blocking plates are arranged in the mixer, and the Z-shaped magnetic channel is arranged in the magnetizer. According to the system and the method, the mounting is convenient, the structure is simple, continuous magnetization can be realized, and the dust-settling effect is good.

Owner:CHINA UNIV OF MINING & TECH

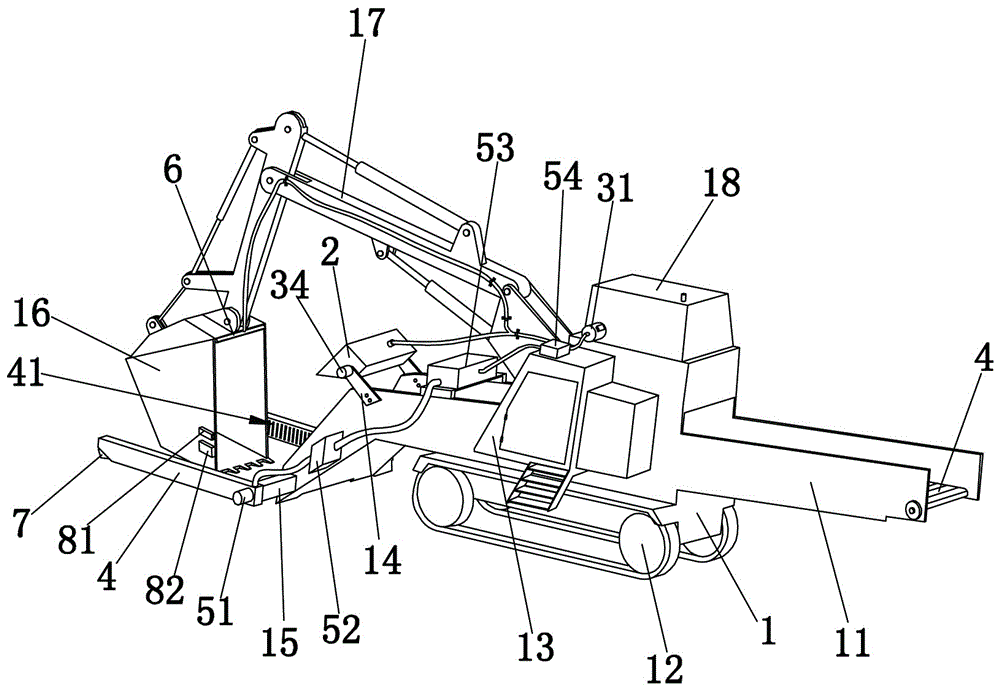

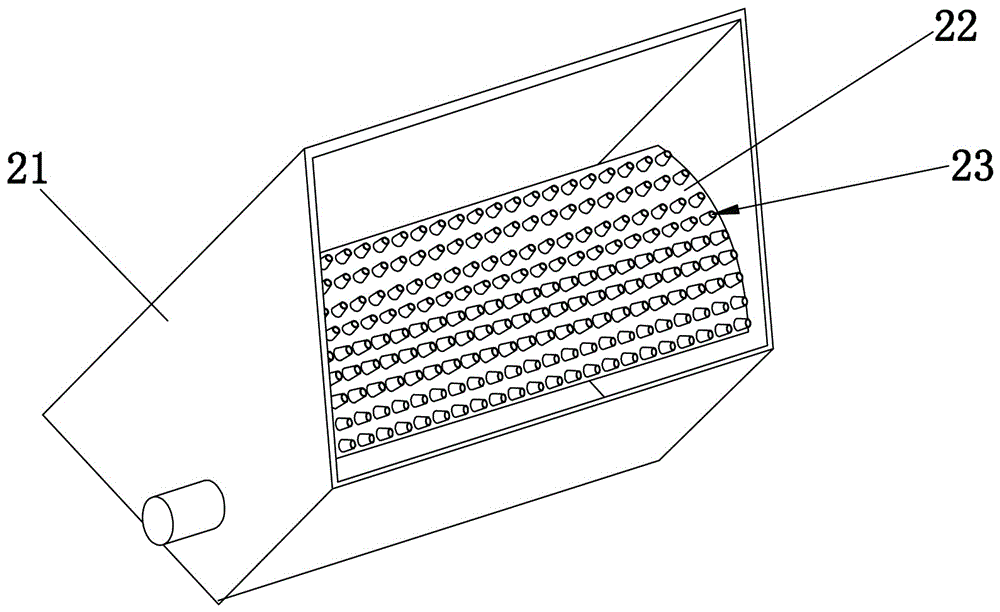

Garbage excavation all-in-one machine

ActiveCN106013306AQuick and effective removalAvoid harmSoil-shifting machines/dredgersTherapeutic effectEngineering

The invention discloses a garbage excavation all-in-one machine, and relates to the field of garbage treatment. The garbage excavation all-in-one machine comprises a machine body. The machine body is provided with a bucket, a conveying trough, a driving cabin and a traveling mechanism, and the conveying trough is provided with a conveying belt. The garbage excavation all-in-one machine further comprises a dust precipitating system and an air purification system. The dust precipitating system comprises a water tank, an atomizer and a sprayer which communicate in sequence through pipes. The air purification system comprises air intake pipelines, an exhaust fan and an air purification box which communicate in sequence through hoses. The garbage excavation all-in-one machine has the beneficial effects that the air purification system and the dust precipitating system can rapidly and effectively remove dust generated during excavation of garbage and purify the air, thereby avoiding injury to workers and pollution to the environment; the sprayer is arranged above the feeding end of the conveying trough; two air intake pipelines are located on the left side and the right side of the bucket correspondingly; and the sprayer and the air intake pipelines are both very close to the excavation point, so that dust and harmful gas are removed immediately when not dispersing yet. The garbage excavation all-in-one machine has the advantage of good treatment effect.

Owner:DATIAN WEST ENVIRONMENTAL PROTECTION TECH CO LTD

Pretreatment method for improving compactness of coal seam water injection hole

InactiveCN104763372AGuaranteed dust suppression effectIncrease flow resistanceSealing/packingPre treatmentCoal

The invention discloses a pretreatment method for improving the compactness of a coal seam water injection hole. After the water injection hole is drilled, an air chamber is artificially manufactured by use of an air expansion capsule, and then compressed air is applied to feeding dry fine expansion powder into the coal seam water injection hole under a certain pressure; the dry fine expansion powder infiltrates in to a pore (crack) region surrounding the hole under the action of the positive pressure of the compressed air; after the dry fine expansion powder goes into the cracks, the flowing resistance of a fluid in the cracks is increased on one hand, and on the other hand, after water is injected in the later period, the powder expands in water, and therefore, the leakage path can be effectively blocked and the loss of water in the water injection hole is obviously reduced, and moreover, the wet degree of the coal can be greatly improved; when the coal is mined, the dust production amount is effectively reduced, the working environment is remarkably improved and the life health of workers is protected.

Owner:CHINA UNIV OF MINING & TECH

Method for controlling building blasting dust

ActiveCN110057261AFall fastGuaranteed dust suppression effectUsing liquid separation agentBlastingRelative humidityClosed space

The invention discloses a method for controlling building blasting dust. An inner air curtain and an outer air curtain are used for controlling dust, the blasting dust is controlled mainly by the inner air curtain first so as to prevent from overflowing, secondary sedimentation is performed on the dust which is not controlled by the inner air curtain between the inner air curtain and the outer aircurtain, and finally, the building blasting dust is located in the outer air curtain so as to prevent the dust from discharging; a water bomb is put before building blasting so as to form a closed space together with the inner and outer air curtains, so that the relative humidity in the closed space reaches more than 95%, and dust suppression during building blasting is facilitated. The water bomb and a liquid nitrogen bomb are put simultaneously and alternately after building blasting; the contact with the dust can be quickly realized, the surface of the dust is wrapped, additionally, the dust is quickly condensed under the action of liquid nitrogen fog drop, the descending speed is increased, and the dust settling effect is guaranteed. The method has the advantages of high dust collecting speed, good dust collecting effect and wide practicability.

Owner:XUZHOU INSTITUTE OF TECHNOLOGY

Compound type environment-friendly dust suppressant as well as preparation and application thereof

ActiveCN107880850AEasy to prepareEasy to store and transportOther chemical processesSodium carboxymethylcelluloseSodium triphosphate

The invention provides a compound type environment-friendly dust suppressant as well as a preparation method and application thereof. The compound type environment-friendly dust suppressant is characterized in that based on the total mass of the dust suppressant, the dust suppressant is prepared from the following components in percentage by mass: 18 to 60 percent of an adhesion composition, 5 to20 percent of a coagulation composition and 15 to 45 percent of a moisture absorbent, wherein the adhesion composition is a composition of polyvinyl alcohol, carboxymethyl cellulose and Na2SiO3; the coagulation composition is a composition of polyacrylamide and sodium tripolyphosphate. The compound type environment-friendly dust suppressant provided by the invention is easy to store and low in cost, and also has a relatively good dust suppression effect; the compound type environment-friendly dust suppressant is especially suitable for dust suppression of a pit road surface of an open coal mine.

Owner:CHINA SHENHUA ENERGY CO LTD +1

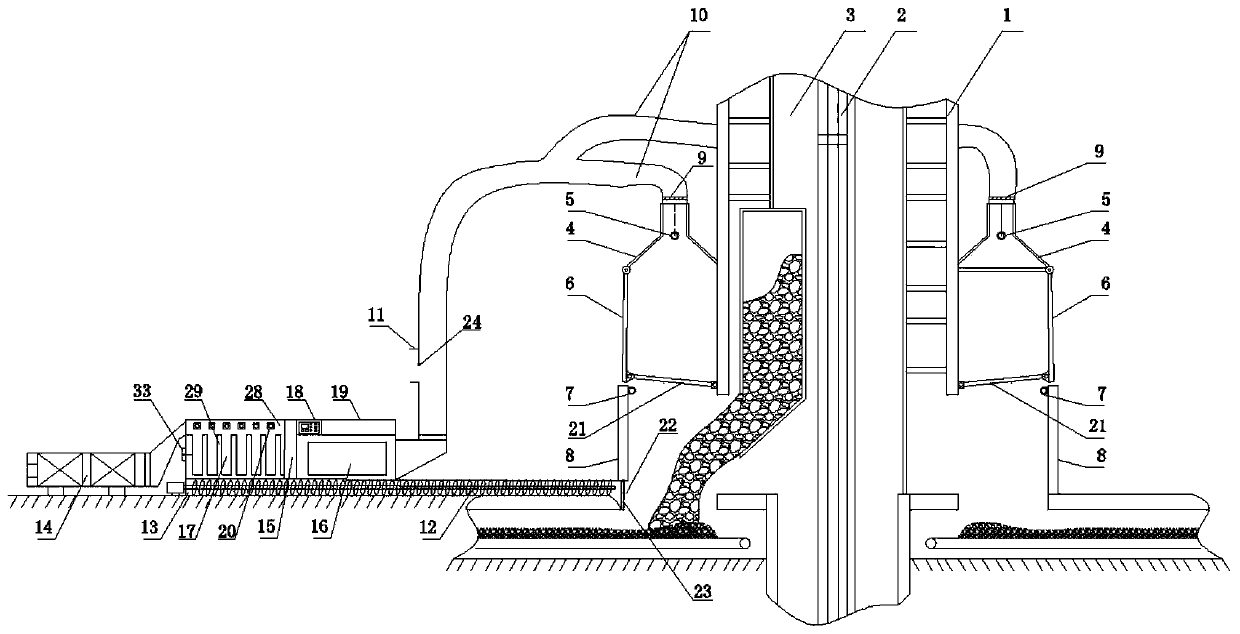

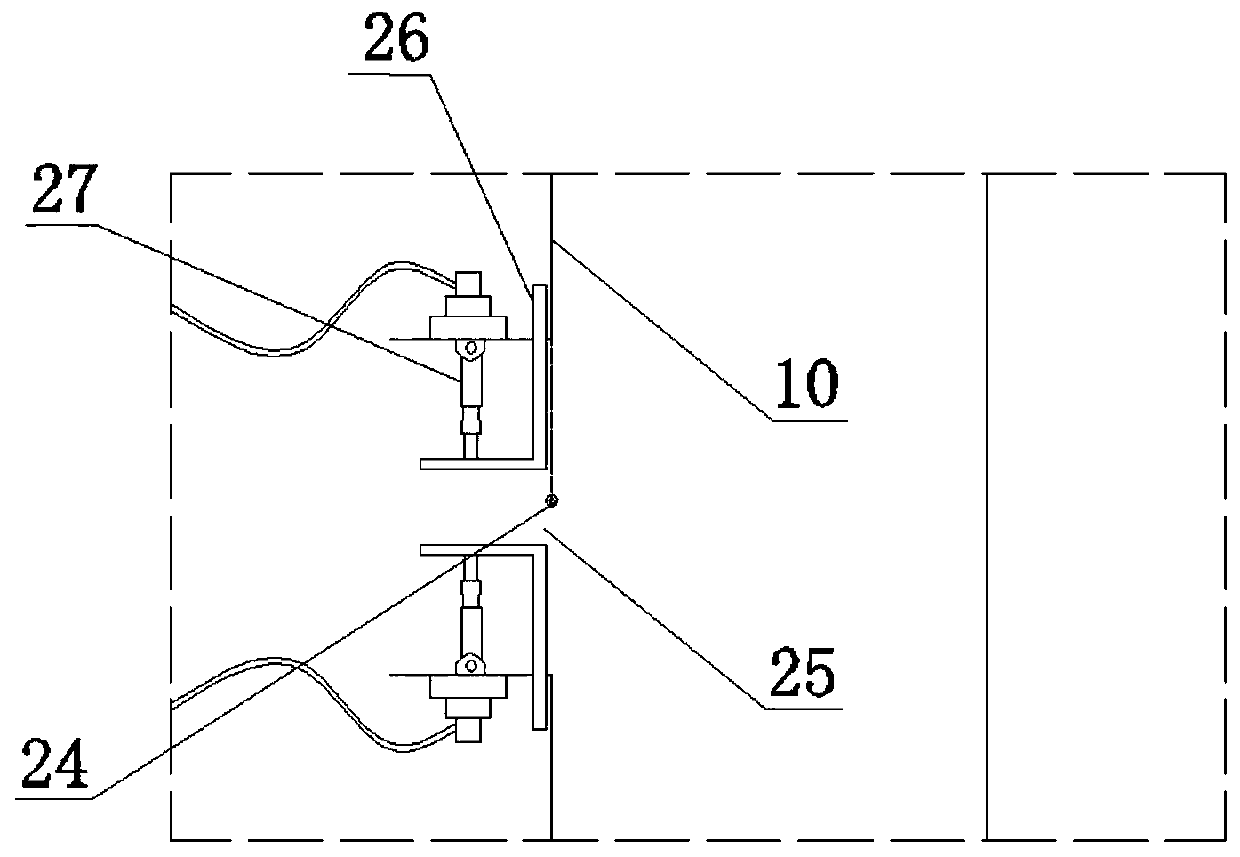

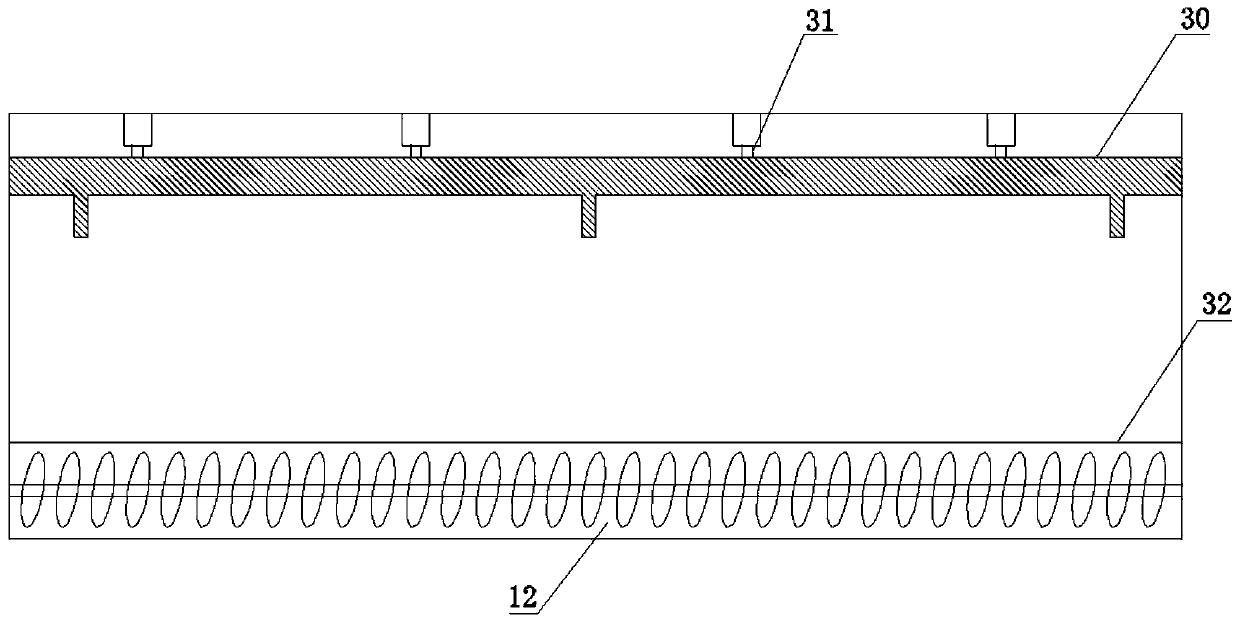

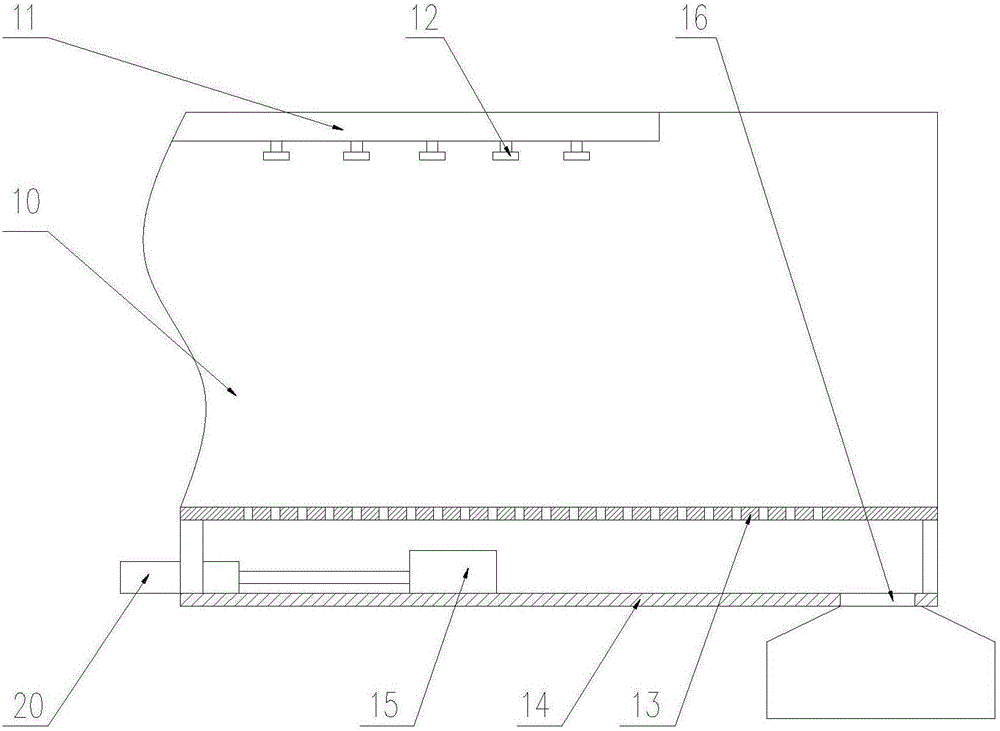

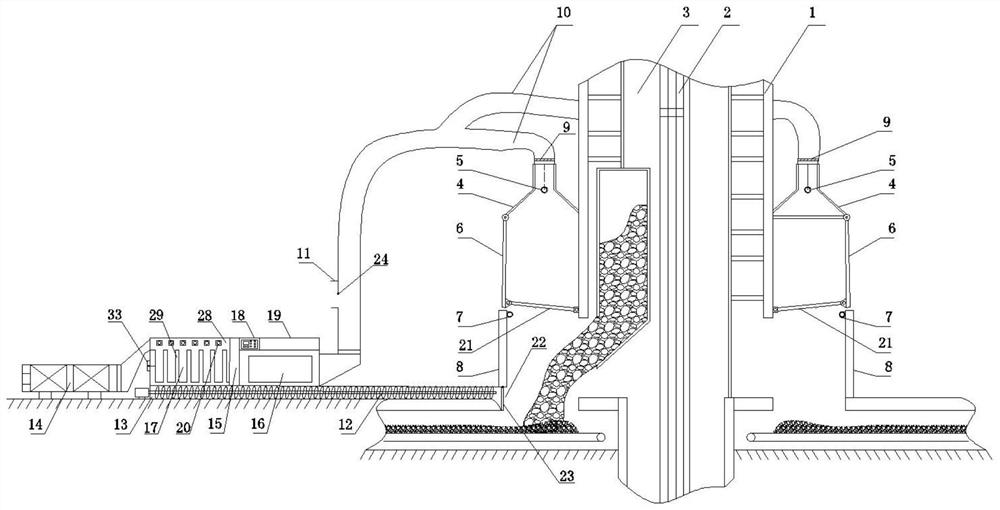

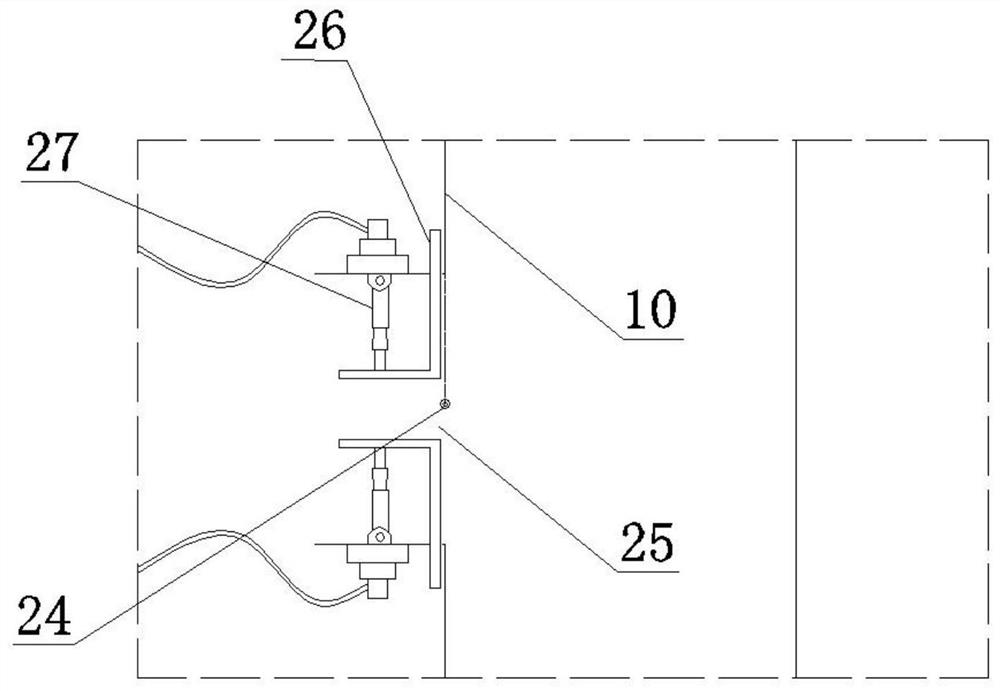

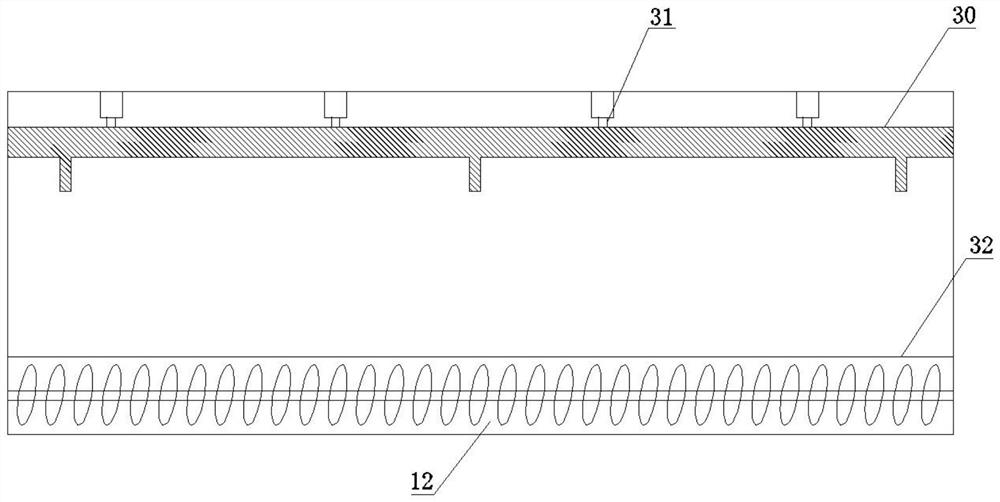

Automatic dust falling system and method for coal unloading point of elevator shaft

ActiveCN110951512AQuickly meet the needs of purificationEmissions are strictly controlledGaseous fuelsAir velocityThermodynamics

The invention discloses an automatic dust falling system and method for a coal unloading point of an elevator shaft. According to the system, two dust collecting mechanisms are arranged on the left side and the right side of the elevator shaft correspondingly, the dust collecting mechanism comprises a dust collection cover, a transparent dust separation plate, a hydraulic support A, a control airdoor, a dust concentration sensor and a gas concentration sensor, an axial flow fan is connected to the two dust collecting mechanisms through a dry dust collector, and a feeding end of a spiral conveyor is arranged below the dry dust collector. The method comprises the steps monitoring the dust concentration near a wellhead of a hoisting well in real time by the dust concentration sensor, sendingthe dust concentration to the controller, judging the average dust concentration on the two sides, starting the axial flow fan according to conditions, controlling the working state of the axial flowwind speed according to the actual situation, controlling and adjusting opening and closing of an air door according to the gas concentration, and controlling the action of a pulse valve according tothe ash deposition state. The system can eliminate raised dust at the vertical shaft tower in the coal lifting and unloading process, can control dust overflow, and is beneficial to protecting the atmospheric environment of a surrounding area and the health of personnel. The method is high in dust removal efficiency and good in dust falling effect.

Owner:徐州宇晟安全环保科技有限公司 +1

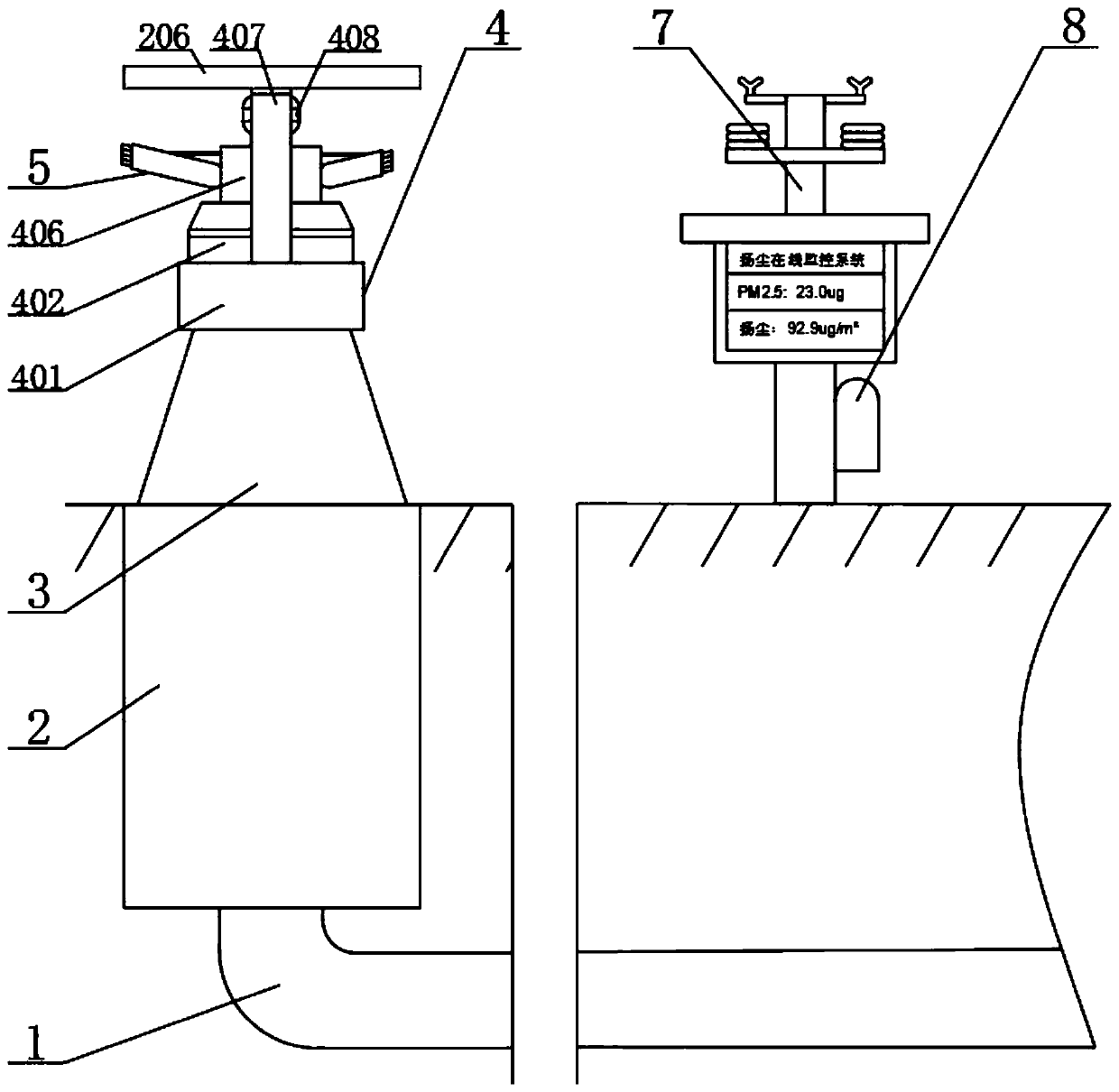

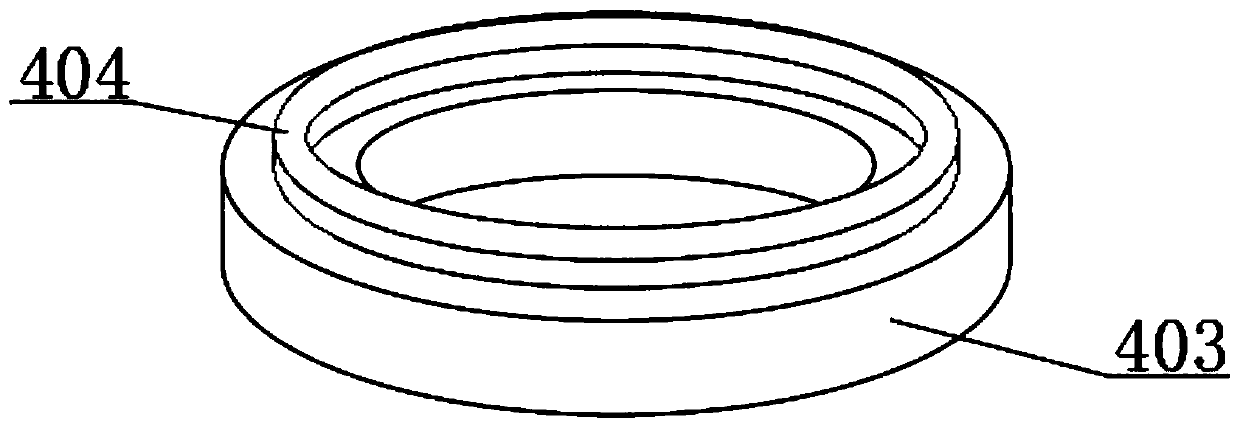

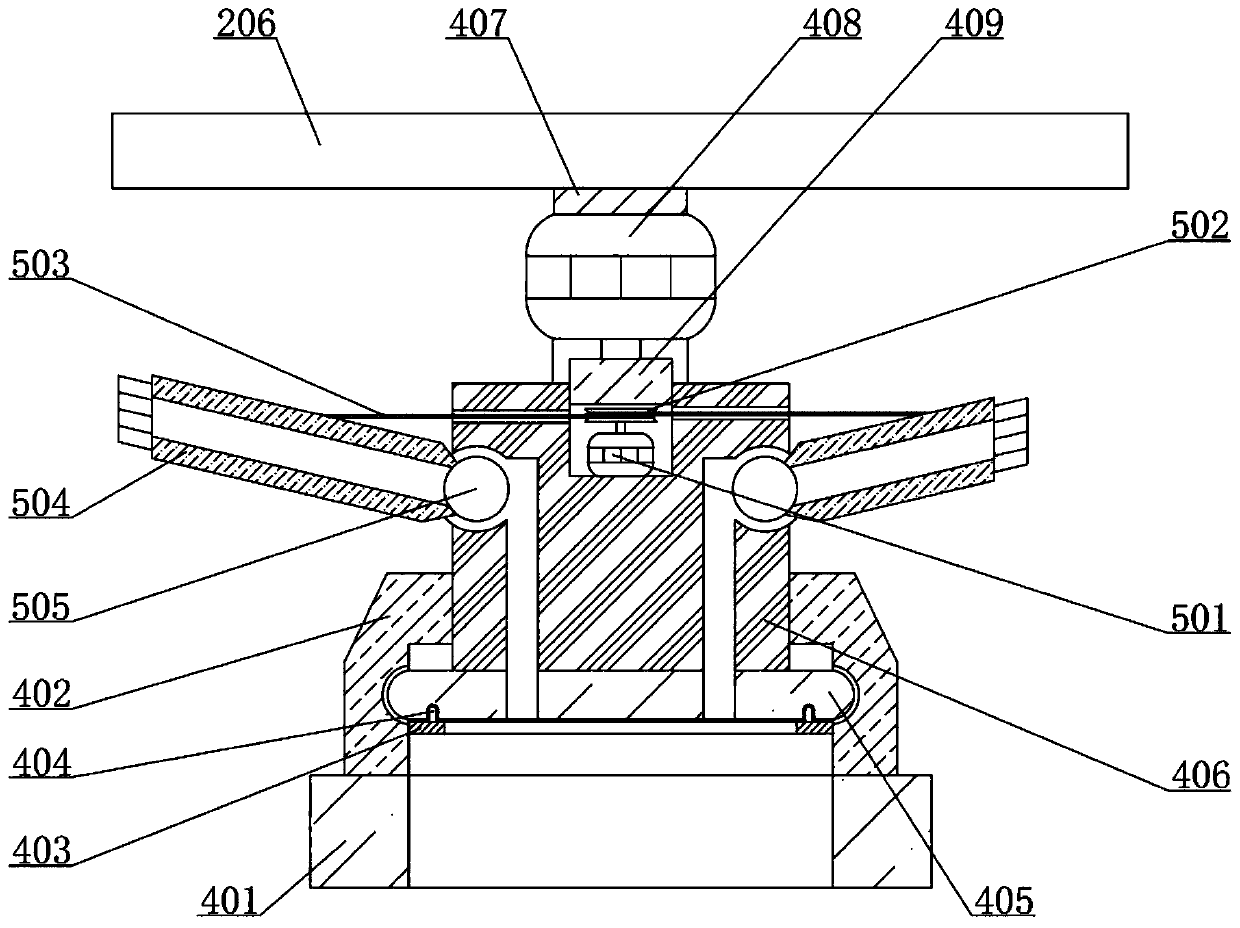

Urban raised dust spraying apparatus and method thereof

InactiveCN111111356AGuaranteed dust suppression effectSave spaceUsing liquid separation agentGreeningStructural engineering

The invention relates to the technical field of greening environmental protection engineering, and especially relates to an urban raised dust spraying apparatus. The apparatus comprises a water pipe,a lifting device, a lifting column and a spraying device, the upper end surface of the water pipe communicates with the lifting device, the lifting column is fixedly connected to the upper end face ofthe lifting device, a conveying pipe is fixedly connected to the interior of the lifting column, the spraying device is fixedly connected to the upper end face of the lifting column, an adjusting device is arranged in the spraying device, a flying dust monitor is arranged on the right side of the spraying device, and a controller is fixedly connected to the right end face of the flying dust monitor. The arrangement of an electromagnetic valve, an electric telescopic rod, a sealing plate and a cover plate makes a spraying head lifted, so it is guaranteed that the spraying head rises in the using process and saves space when not used, the spraying head is very convenient to use, spraying can be effectively conducted in time, the spraying area can be controlled, online monitoring is achieved, and the good dust suppression effect is achieved.

Owner:湖南汉坤实业有限公司

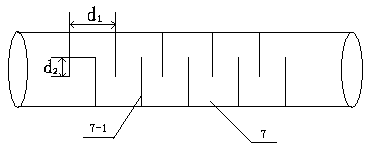

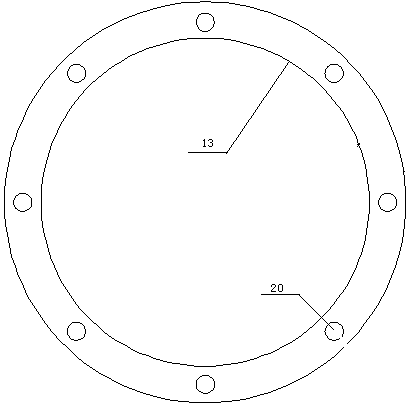

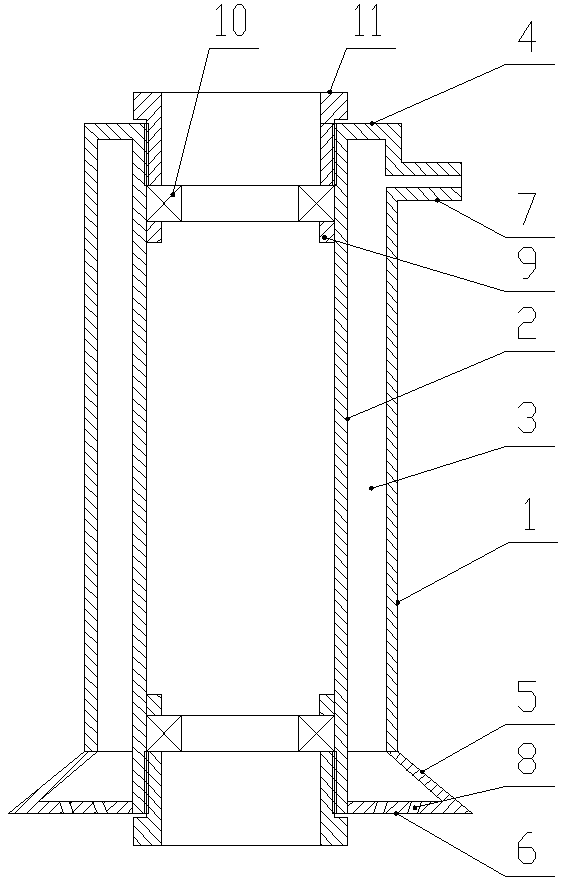

Drill bit cooling dust-proof device

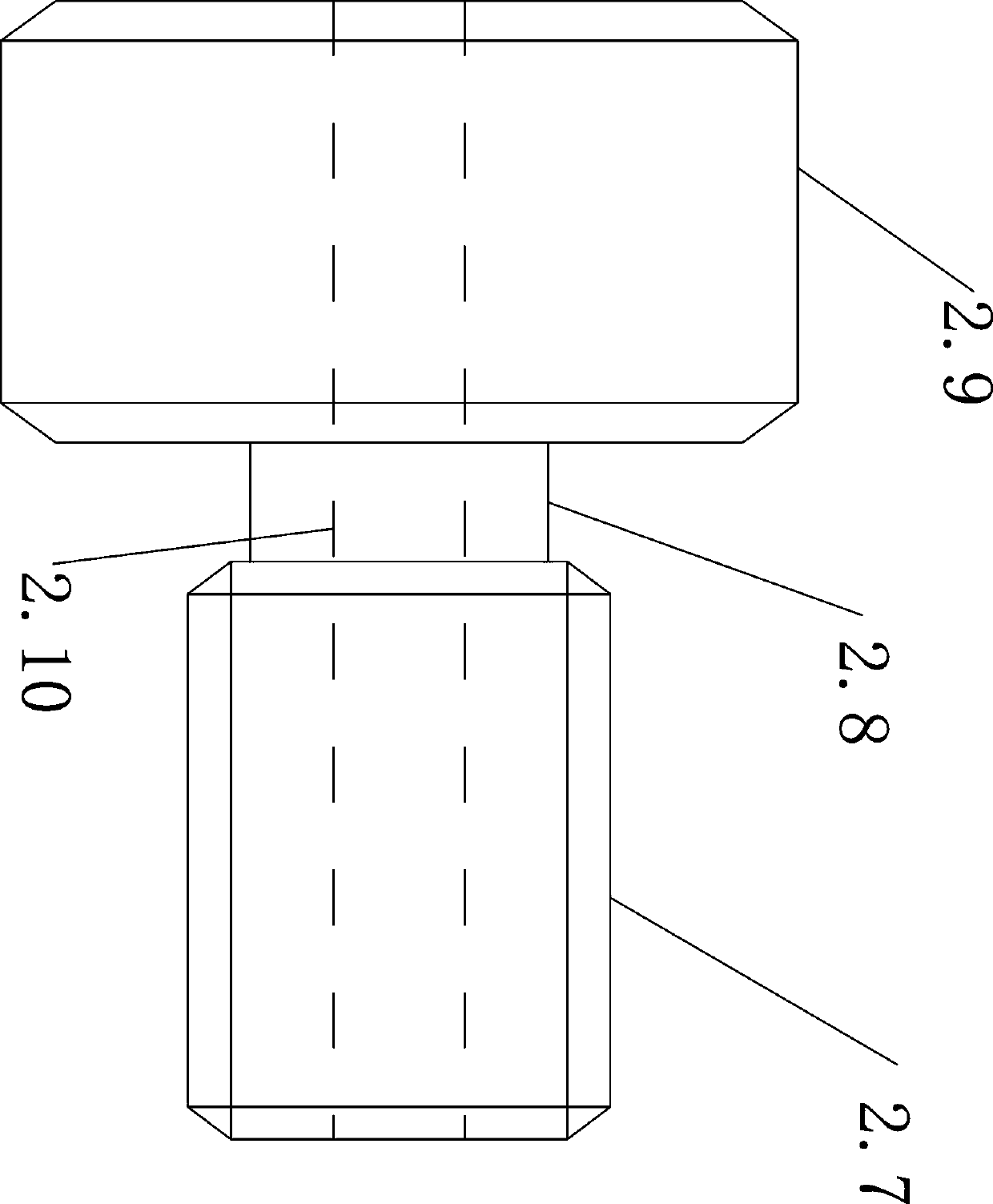

ActiveCN111535762ATo cool downGuaranteed dust suppression effectEarth drilling toolsConstructionsDrill bitPhysics

A drill bit cooling dust-proof device comprises an outer cylinder body and an inner cylinder body both in a vertical arrangement, wherein the inner cylinder body is coaxially arranged inside the outercylinder body, an annular cavity is formed between the outer cylinder body and the inner cylinder body, and the upper ends of the inner cylinder body and the outer cylinder body are fixedly connectedthrough an upper annular plate; the lower end of the inner cylinder body is lower than the lower end of the outer cylinder body, and a conical barrel is fixedly connected to the lower end of the outer cylinder body; the structure of the conical barrel is thin in the upper and thick in the lower, the lower end of the conical barrel and the lower end of the inner cylinder body are fixedly connectedthrough a lower annular plate, and a pipe joint is arranged on the upper part of the outer cylinder body; a plurality of nozzles are evenly arranged on the lower annular plate in the circumferentialdirection, and an upper bearing assembly and a lower bearing assembly are arranged on the upper and lower parts of the inner wall of the inner cylinder body correspondingly. According to the device, the spread of dust during the construction of the drill bit is effectively prevented, and an auxiliary effect of cooling the working drill bit is achieved, so that the physical health of constructors is greatly guaranteed, and at the same time, the service life of the drill bit is prolonged, and the construction level is improved.

Owner:HENAN POLYTECHNIC UNIV

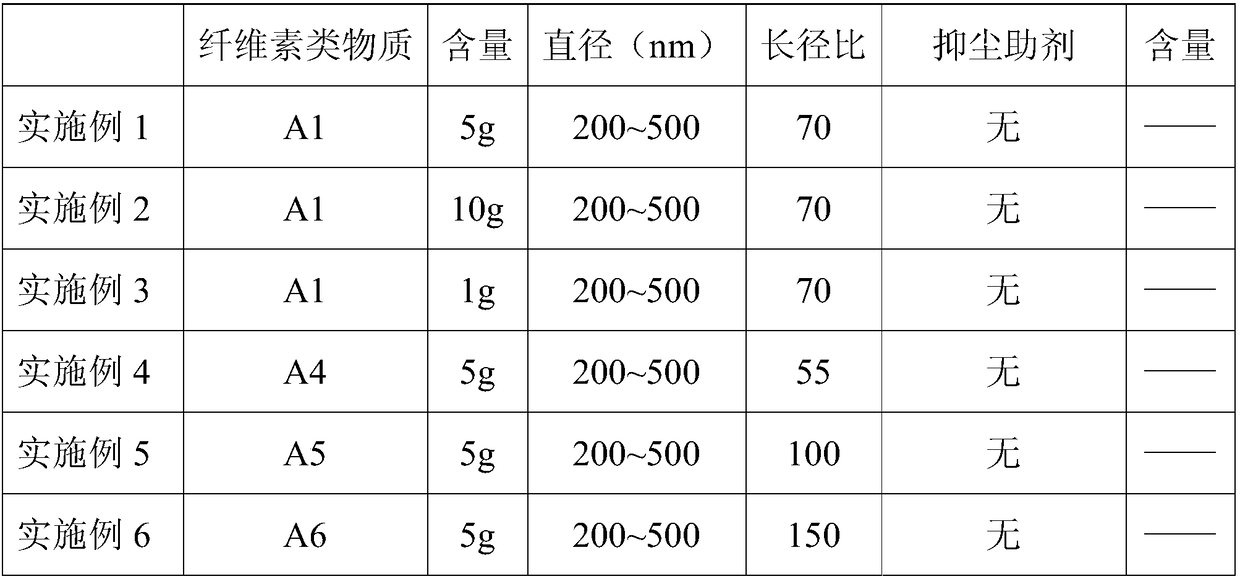

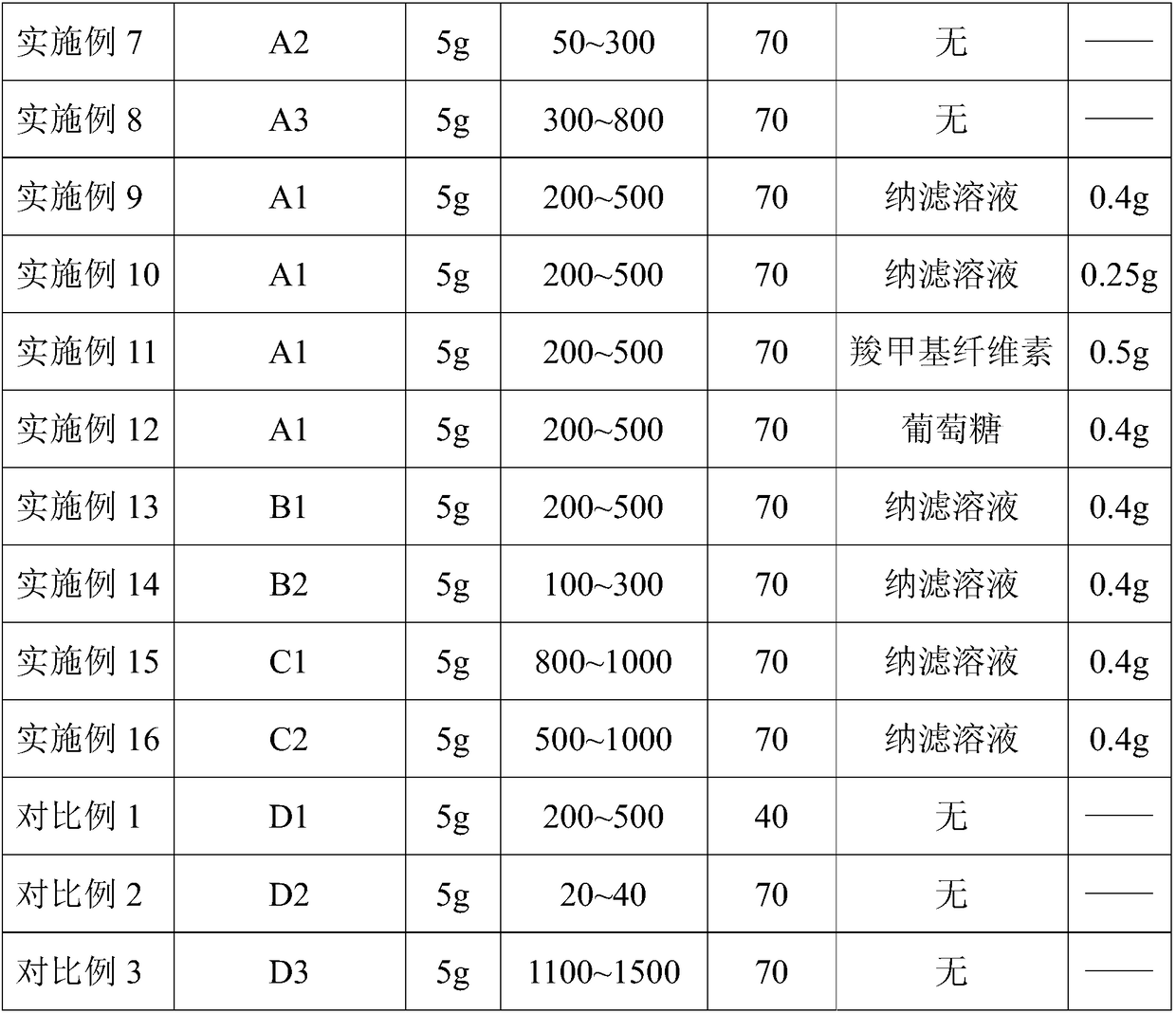

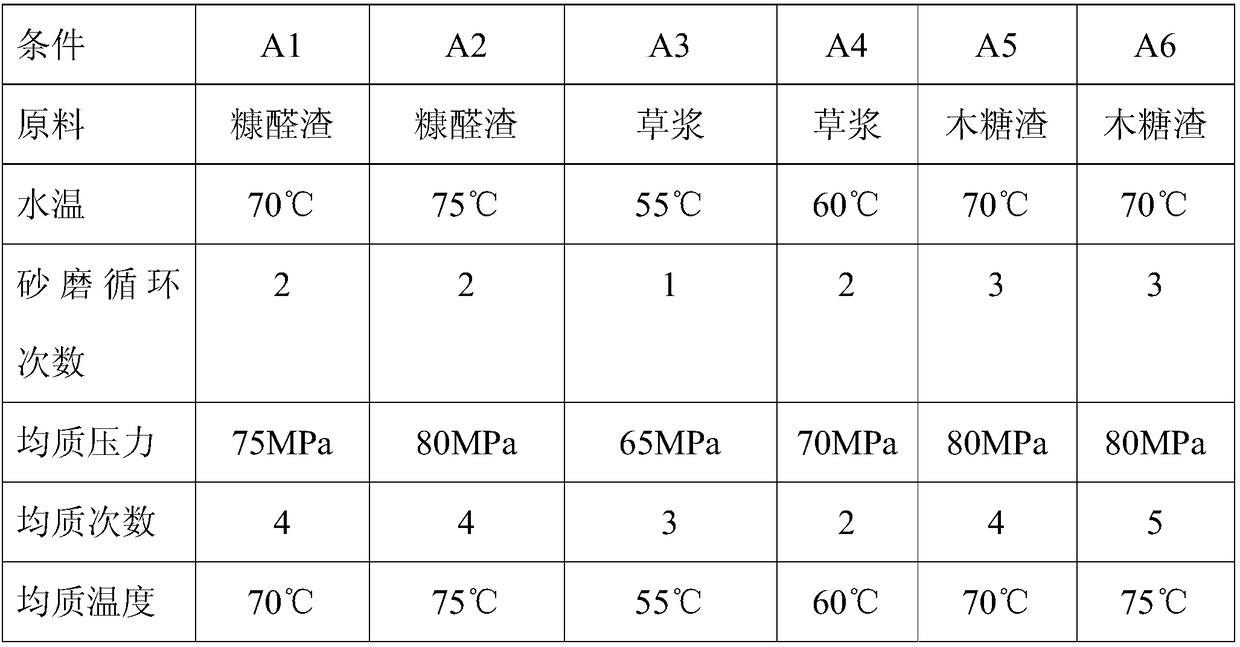

Dust suppressant, preparation method and application

ActiveCN108865071AFast film formationDust suppression cycle is longOther chemical processesDust removalCelluloseChemistry

The invention relates to a dust suppressant. The dust suppressant comprises water and cellulose matters, wherein the cellulose matters are dispersed into the water; the content of cellulose matters is1 to 10wt%; more than 80wt% of components (except water) is the cellulose matters; the diameter of the cellulose matter is 50 to 1000nm, and the ratio of length to diameter is greater than or equal to 50. The dust suppressant has the advantages that the cellulose matter with special size is selected; the cellulose matters within the size are mutually bonded to form a network; the dust suppressantis accelerated to form a film, the fine dust is firmly caught, and is prevented from flying into the air to form secondary dust, and the dust suppressing cycle is long.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

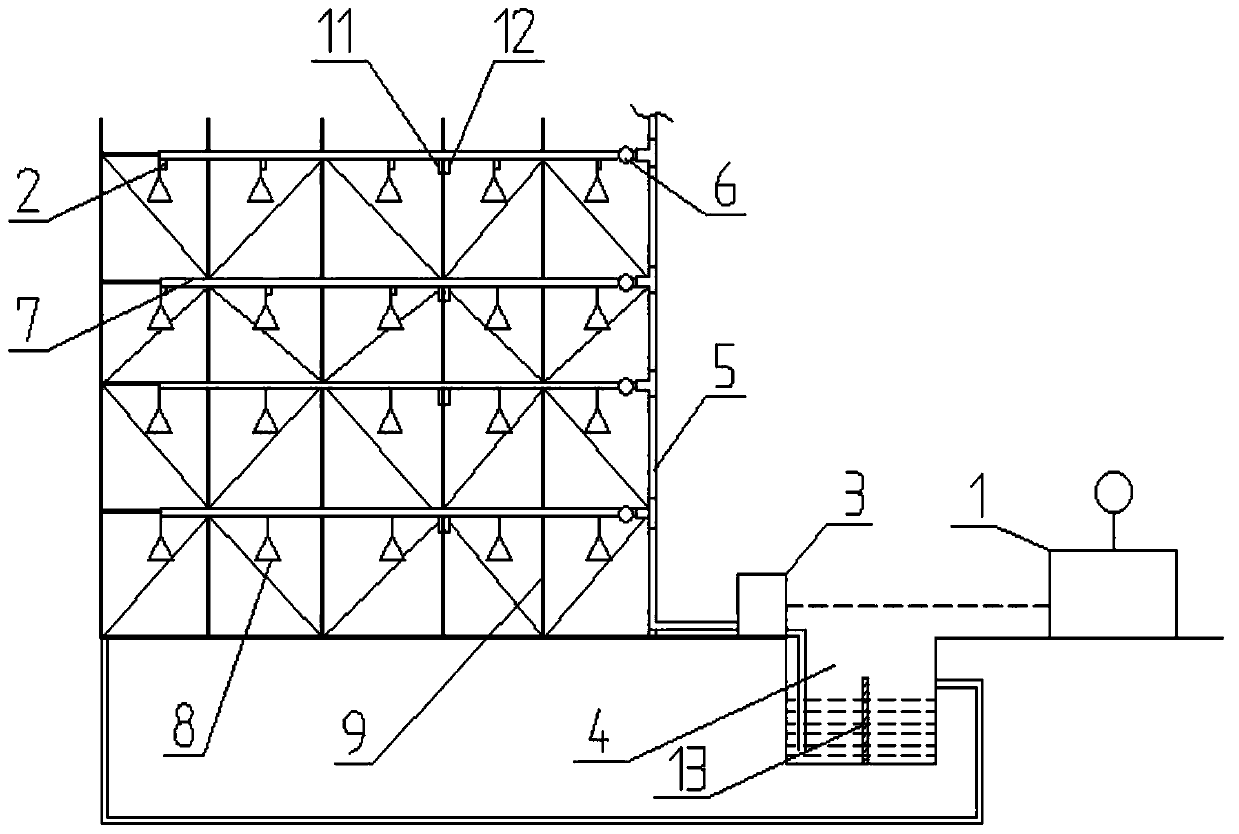

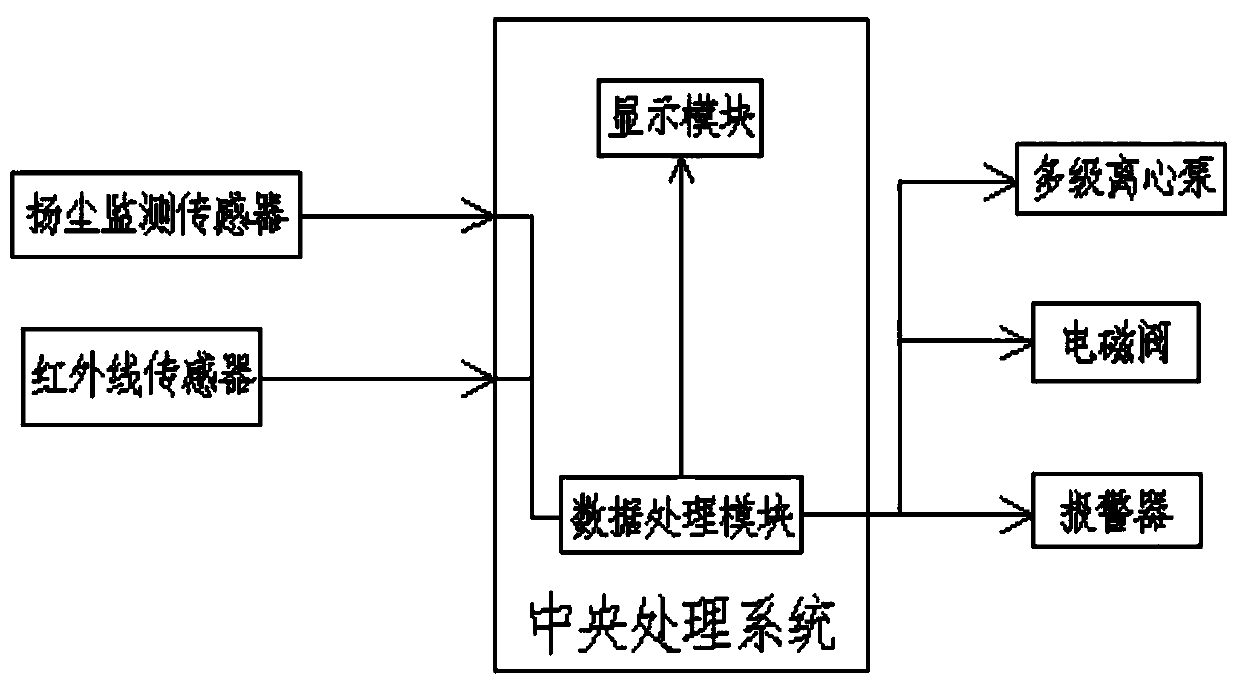

A raised dust monitoring and dust reduction linkage system attached to a scaffold

InactiveCN109772069APrecise pollution preventionAvoid tarnishingUsing liquid separation agentScaffold accessoriesSprayerSolenoid valve

The invention discloses a raised dust monitoring and dust reduction linkage system attached to a scaffold, and belongs to the technical field of building construction. The system includes a raised dust monitoring system including raised dust monitoring sensors for real-time raised dust data monitoring; and an automatic water feeding system including a multi-stage centrifugal pump, a solenoid valve, atomization sprayer heads, a vertical water supplying pipeline and horizontal water supplying pipelines for atomization and dust reduction. During atomization and dust reduction, an alarm system collects person movement information in an operation range, and effectively gives alarms to protect workers from being sprayed with mist containing raised dust particles, achieving a more humanized effect. In addition, the mist containing raised dust particles is collected and reused on an operation platform, thus greatly saving the equipment cost, effectively saving the water resource, and achievinga wide dust reduction range, significant dust reduction effects, and other advantages.

Owner:CHINA MCC17 GRP

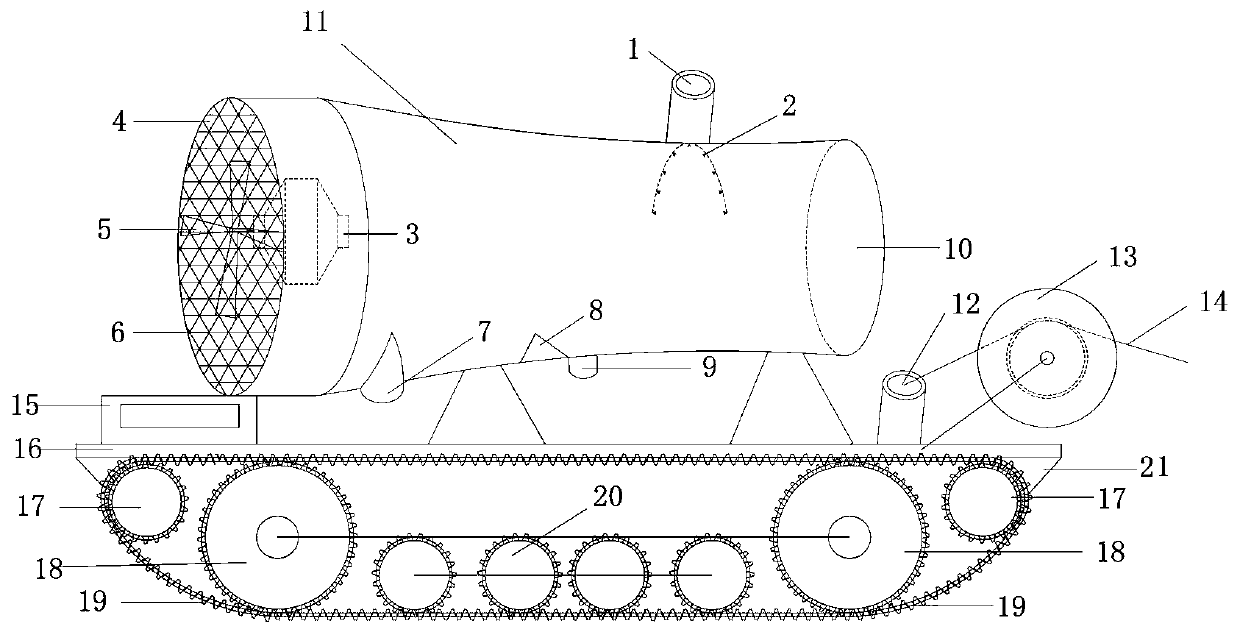

Remote control self-moving type pneumatic dust removal device

InactiveCN110985096AAvoid safety hazardsEasy to useDust removalFire preventionAtomizer nozzleMarine engineering

The invention relates to a remote control self-moving type pneumatic dust removal device. A pneumatic dust removal structure is installed at the top of a pneumatic self-moving type crawler flatbed vehicle, and the pneumatic dust removal structure includes an outer shell. The outer shell is of a hollow tubular structure, and openings communicating with an inner cavity of the outer shell are formedin both ends of the outer shell, wherein an air inlet is formed in one end, and an air outlet is formed in the other end. An air suction device is installed at the air inlet, and an atomizing nozzle assembly is installed in the outer shell. A water inlet pipe port which communicates with the atomizing nozzle assembly is installed on the outer wall of the outer shell. The remote control self-movingtype pneumatic dust removal device has the beneficial effects that contaminated air in a roadway is sucked into the outer shell, the air passes through water mist sprayed from the atomizing nozzle assembly and then is purified, the pneumatic self-moving type crawler flatbed vehicle drives the pneumatic dust removal structure, a power source is compressed air, and the compressed air is used as driving force to drive a pneumatic motor to work, so that the potential safety hazards of electric drive is eliminated, the problems of difficult movement and high energy consumption of dust removal devices are solved, and more safety and reliability are achieved.

Owner:SHANDONG LINENG LUXI MINING IND CO LTD

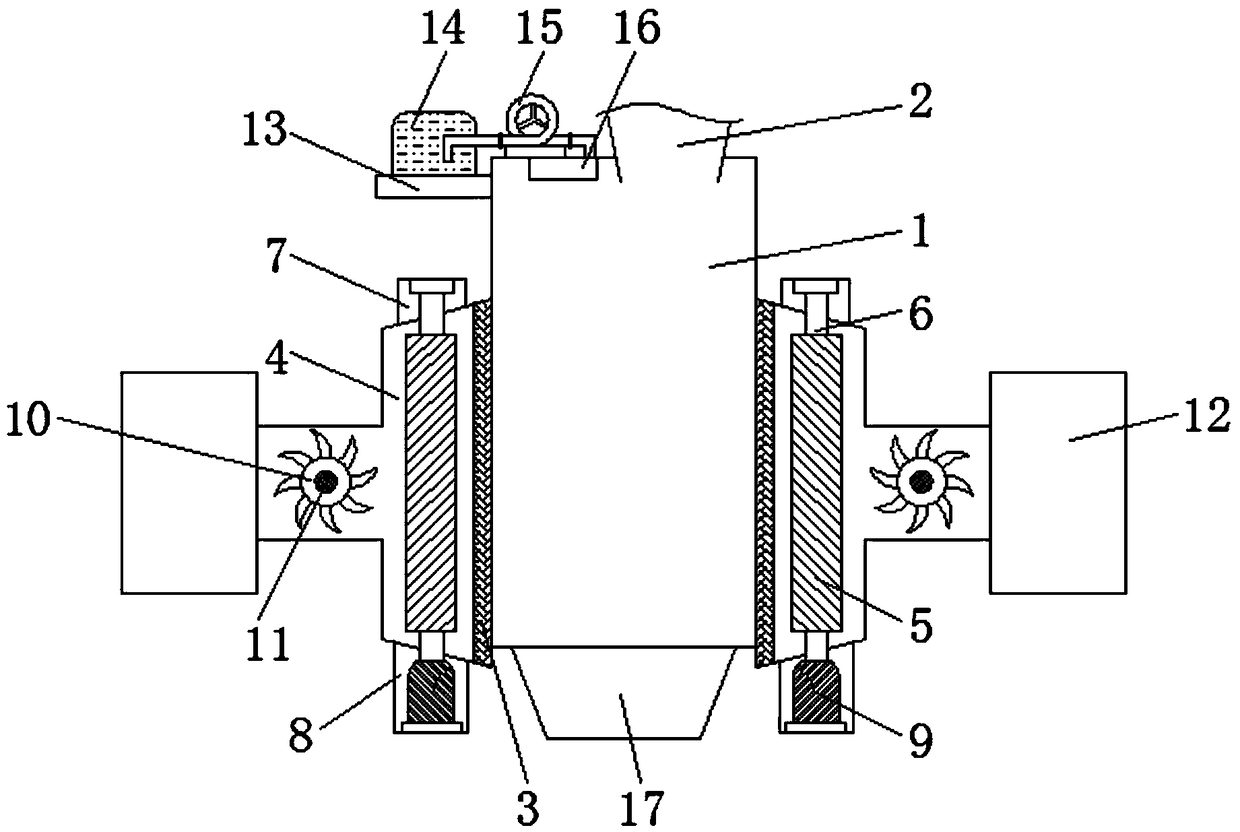

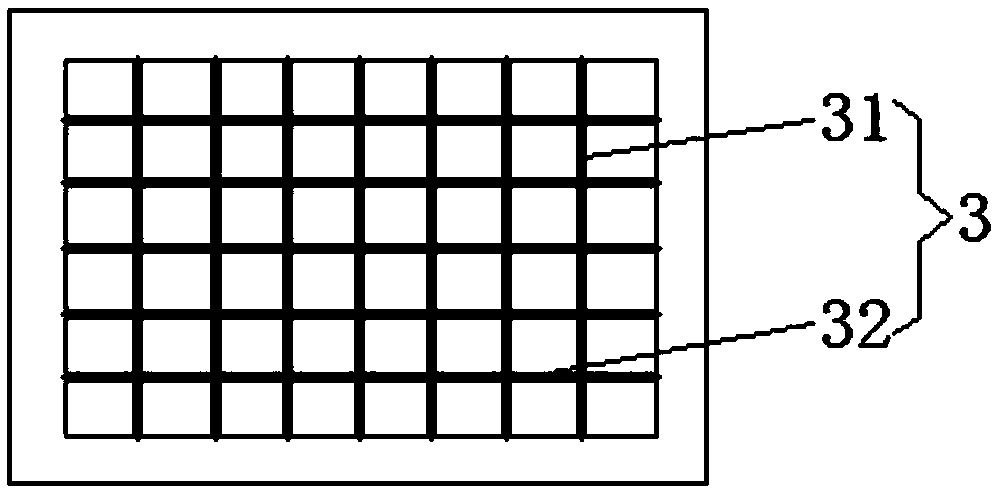

Dust removal system based on mine cooling system

InactiveCN106437819AReduce humidityGuaranteed cooling effectDust removalFire preventionCooling effectEngineering

The invention aims to overcome the shortcomings of the prior art, and provides a dust removal system based on a mine cooling system; the dust removal system is lower in investment and running cost, and can guarantee the cooling effect and the dust removal effect at the same time. The dust removal system includes several dust removal water pipes arranged at the upper wall of a dust removal passage and extended long the dust removal passage, dust removal nozzles are respectively arranged on every dust removal water pipe; a dust removal steel rail is paved on the bottom wall of the dust removal passage, and the dust removal steel rail comprises a dust leaking plate located at the upper part, a walking plate located at the lower part, and a supporting beam supported between the dust leaking plate and the walking plate; several dust leaking holes are arranged on the dust leaking plate, one end on the walking plate adjacent to the working place is provided with a dust pushing oil cylinder and a V-shaped pushing head connected to a piston rod of the dust pushing oil cylinder; the other end of the walking plate is provided with a dust leaking opening, the width of the dust leaking opening is less than the width of the pushing head, the sunken part of the pushing head is opposite to the dust leaking opening, and used for returning the dust on the walking plate to the dust leaking opening.

Owner:CHONGQING HEQU JIUFENG COAL CO LTD

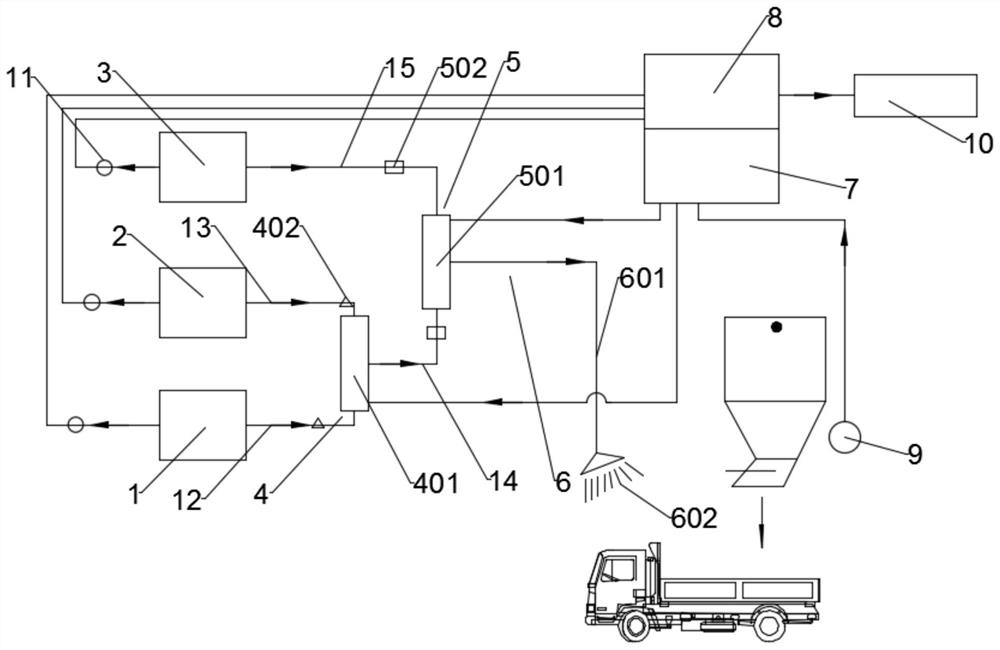

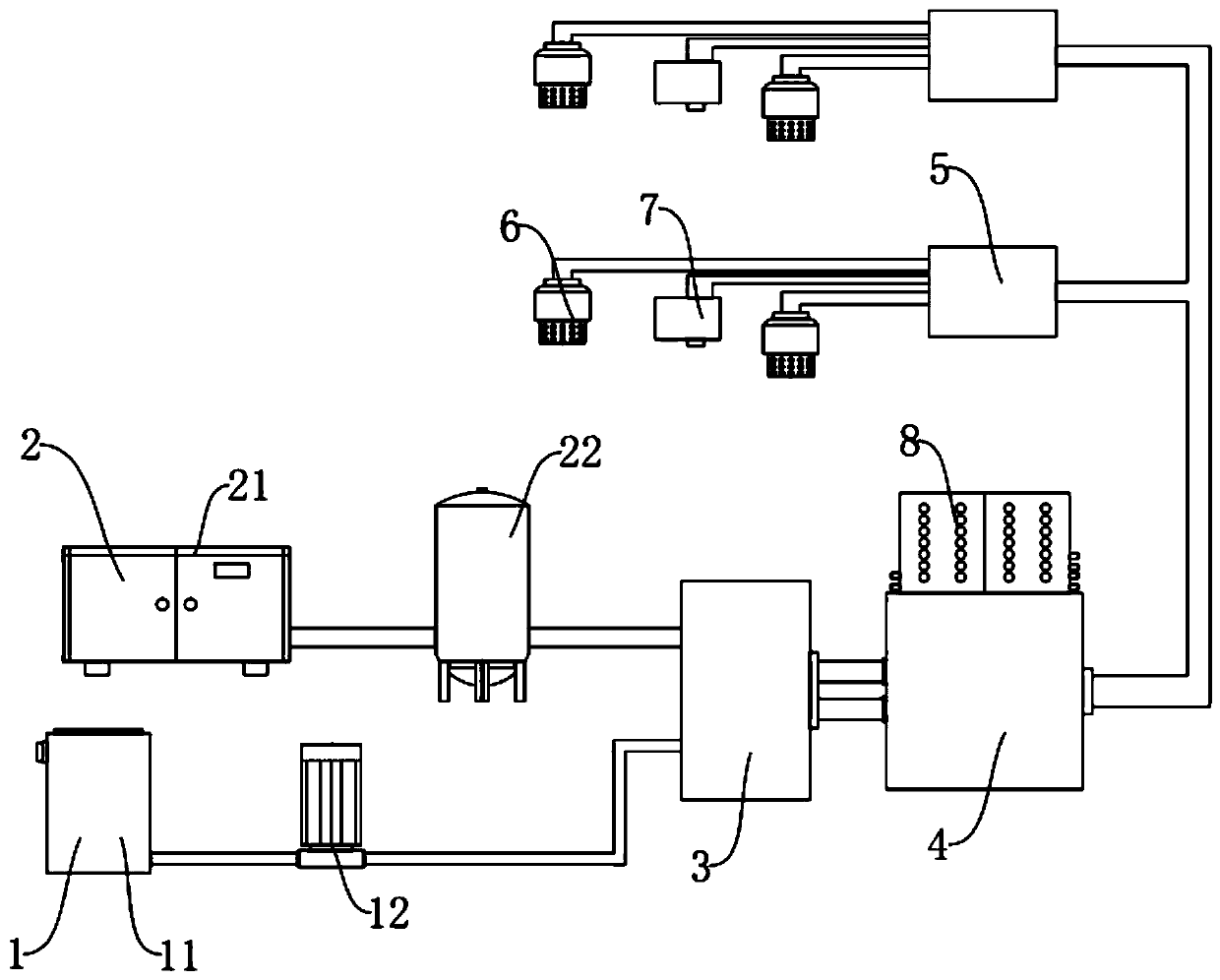

Intelligent dry fog dust suppression system and dust suppression method for automobile receiving tank

InactiveCN112495099AGuaranteed dust suppression effectImprove economyUsing liquid separation agentControl systemGas supply

The invention discloses an intelligent dry fog dust suppression system of an automobile receiving tank. The system comprises a control system, and an air supply system, a water supply system and a dust inhibitor supply system, which are in communication connection with the control system, the control system regulates and controls the overall on-off and mixing-proportioning of the air supply system, the water supply system and the dust inhibitor supply system according to the change of dust concentration data collected on a work site; the dust inhibitor supply system and the water supply systemare connected through a mixing adjustment assembly to obtain a constant-pressure mixed solution containing a dust inhibitor, the mixing adjustment assembly is connected with the air supply system through a gathering adjustment assembly, and the gathering adjustment assembly is connected with a terminal spraying pipeline. The mixing adjustment assembly and the gathering adjustment assembly are connected with the control system through a control loop. The concentration of the dust inhibitor is intelligently regulated and controlled, and the most reasonable dust / inhibitor proportion is selectedaccording to different dust properties and different dust concentrations, so that the dust inhibition effect is guaranteed, and the economical efficiency is also considered.

Owner:北京牧之科技有限公司

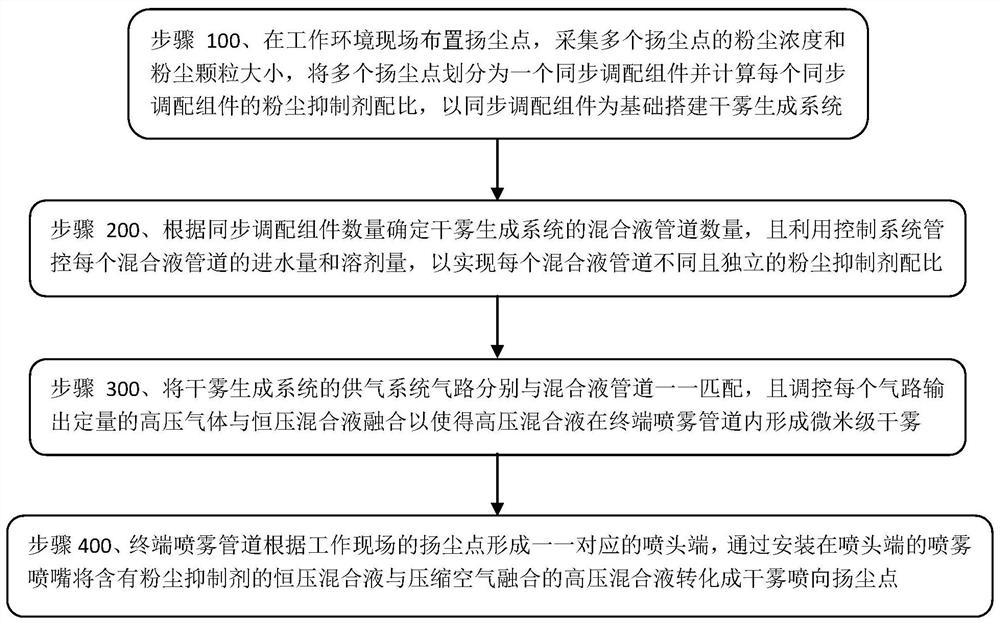

Micron-sized dry fog dust suppression system

InactiveCN110652813AHigh outputAvoid wasteful situationsUsing liquid separation agentAssembly lineGas supply

The invention discloses a micron-sized dry fog dust suppression system. The system comprises a water supply module and an air supply module, the output ends of the water supply module and the air supply module are both communicated with a water-air distributor, the output end of the water-air tube of the water-air distributor is connected with a dry fog machine, the dry fog machine is communicatedwith a plurality of sub-control boxes through connecting tubes, and the sub-control boxes are communicated with dry fog spray heads through connecting tubes; and the sub-control boxes are electrically connected with a laser dust sensor, the plurality of sub-control boxes are electrically connected with a PLC, and the PLC is connected with the water-air distributor through a wire. The dust suppression system can monitor dusts on a processing assembly line in real time through the laser dust sensor arranged in a specific area, and when the dust concentration is too high, a model is transmittedto the PLC, the PLC controls the water-air distributor to increase the water-air output, and the sub-control boxes are turned on to make a large amount of dry fog nozzles at the corresponding positions to participate in dust suppression work, so that the system has high applicability, avoids the wastes of water-air resources, and has a good dust suppression effect.

Owner:合肥合安智为科技有限公司

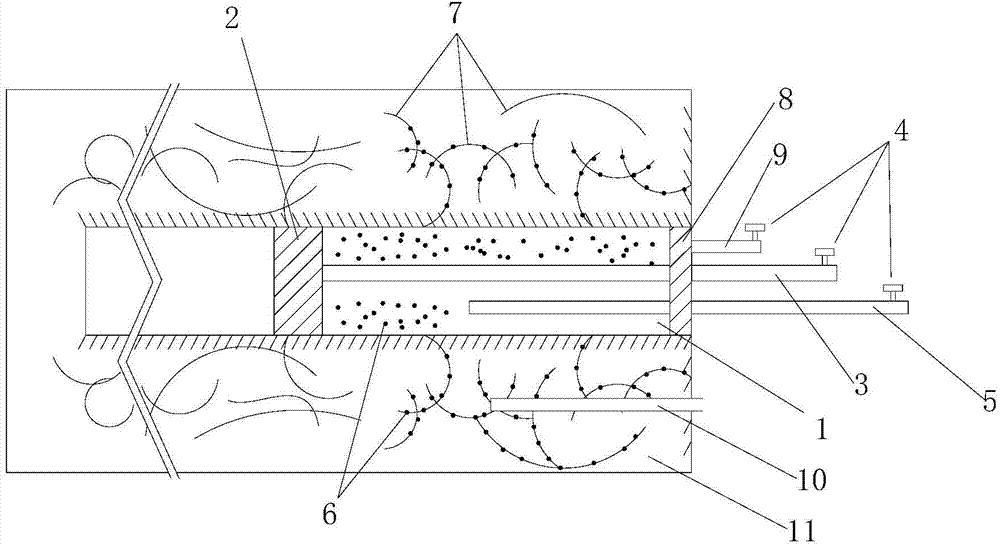

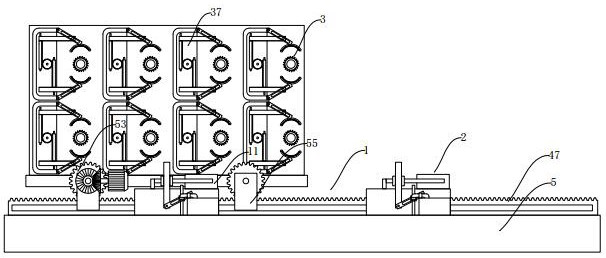

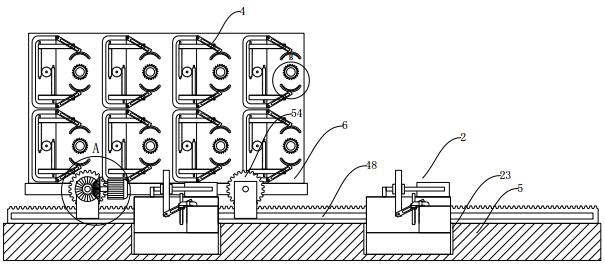

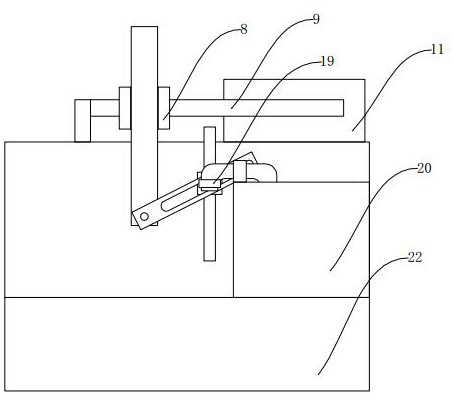

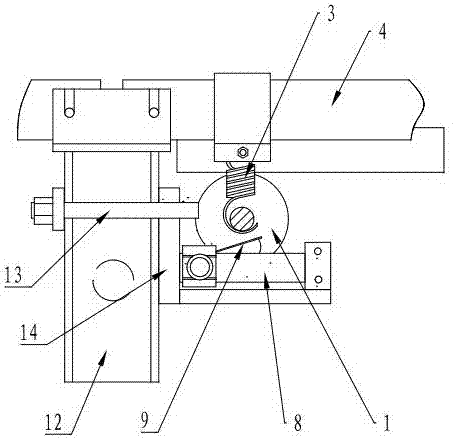

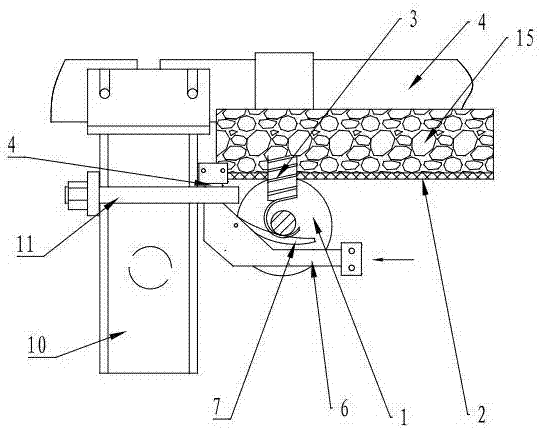

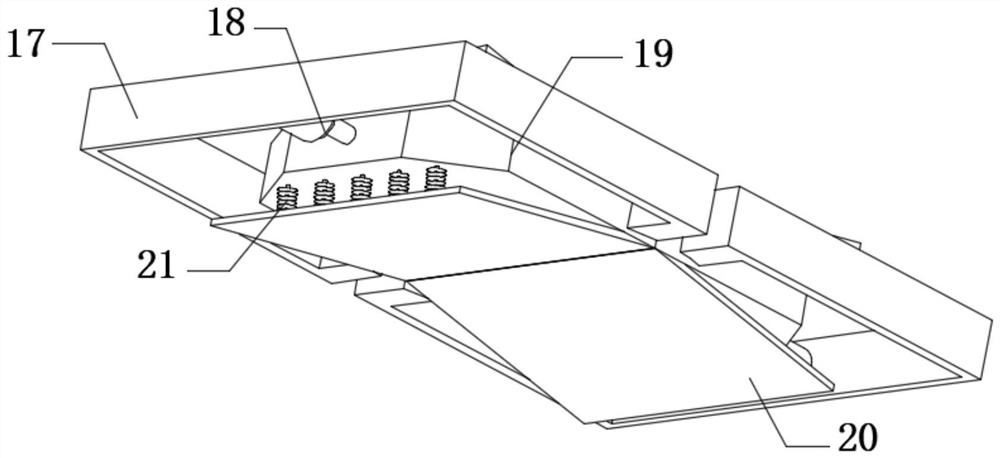

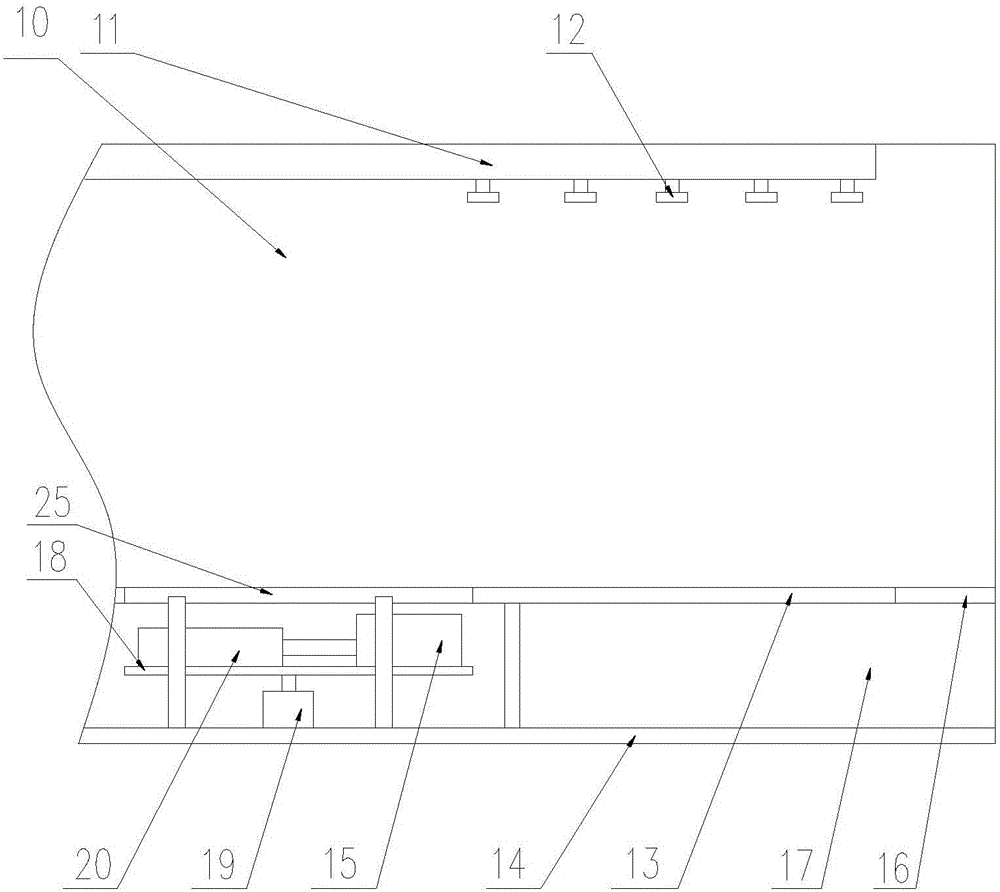

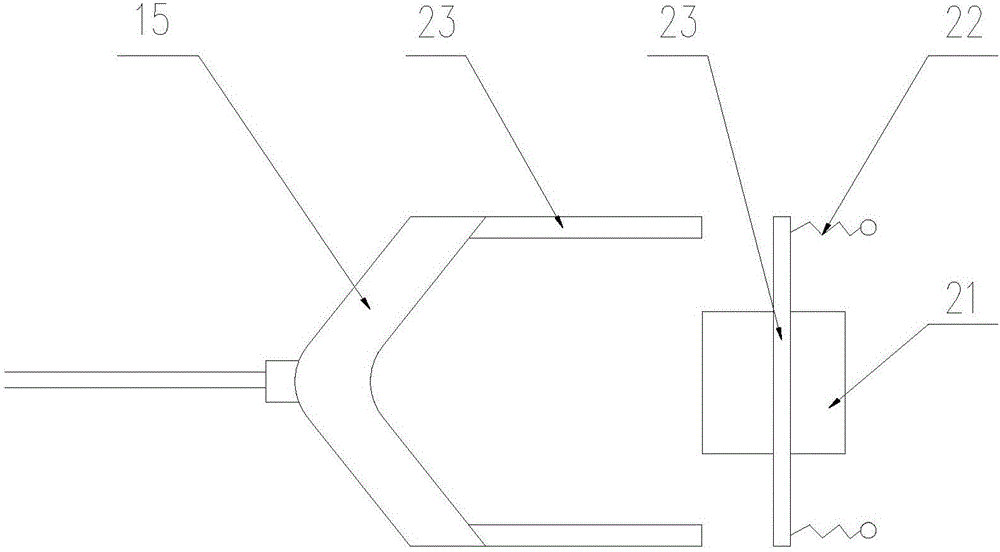

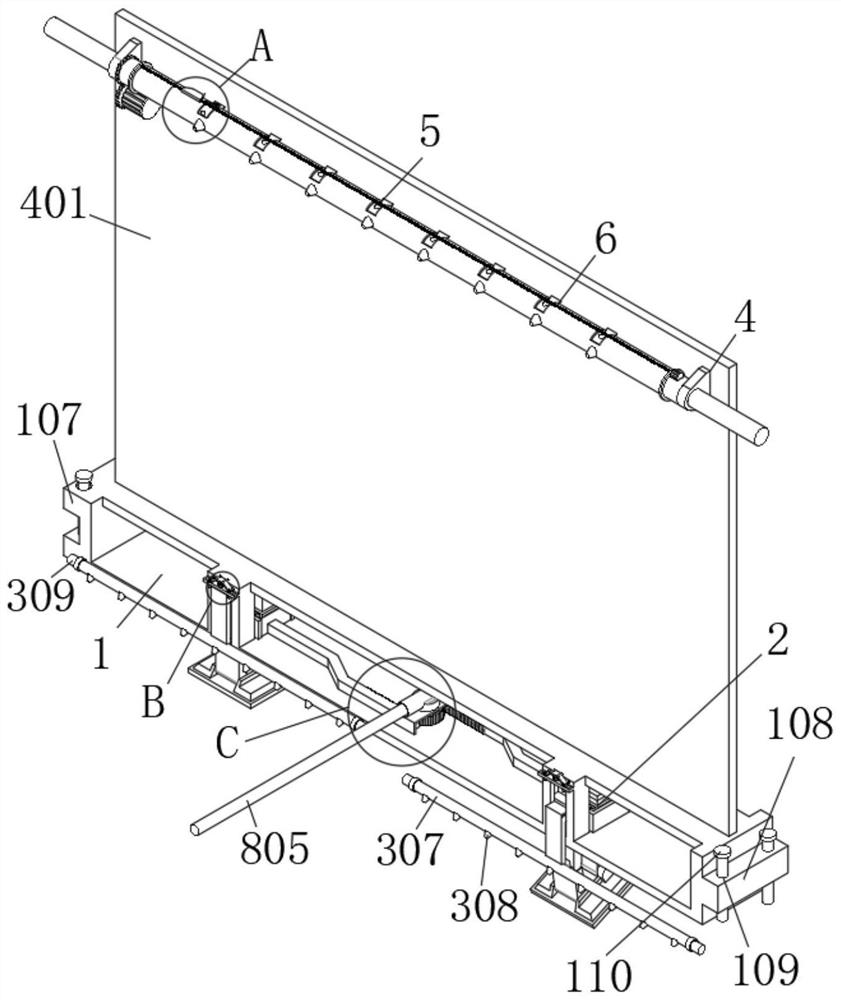

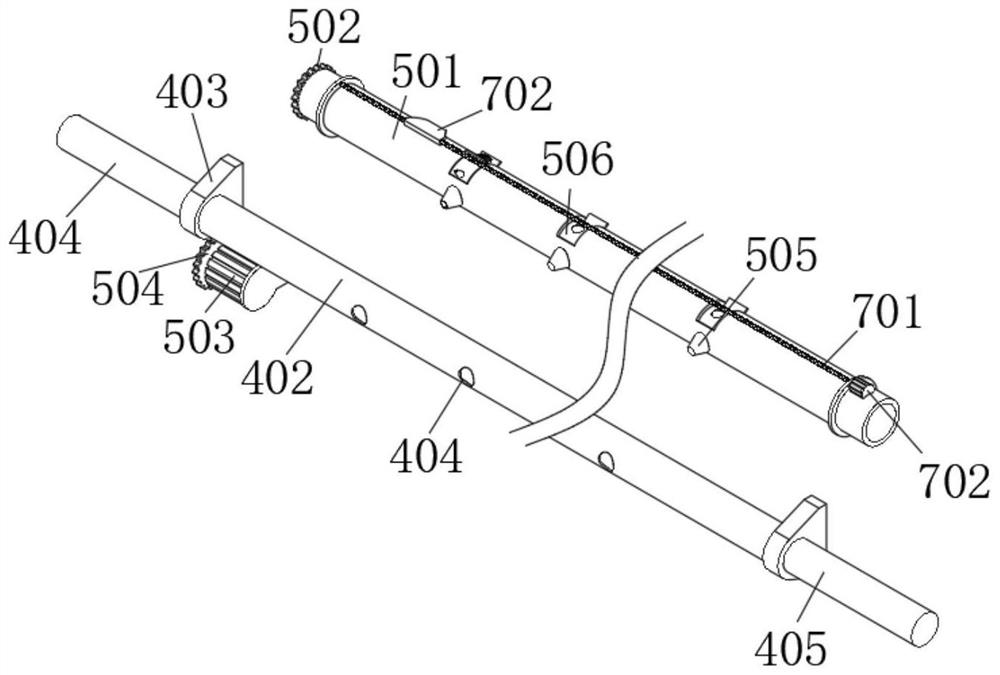

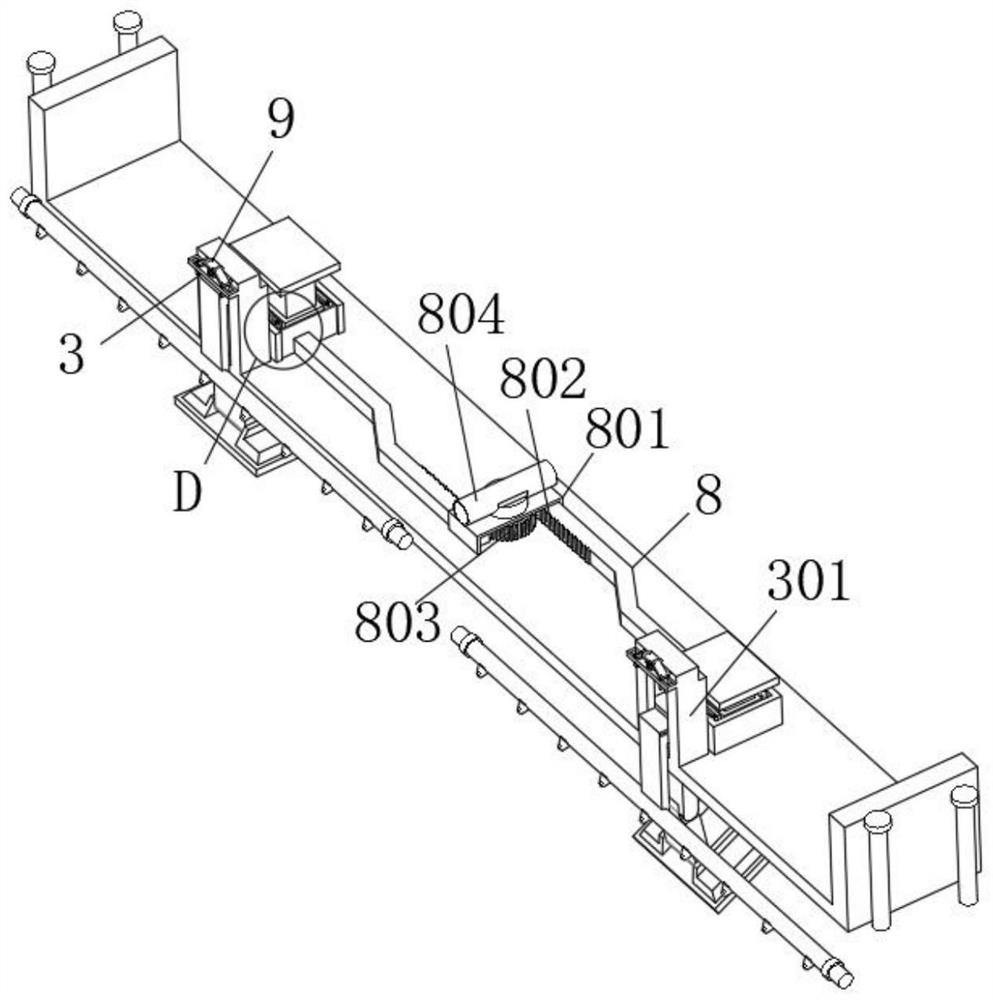

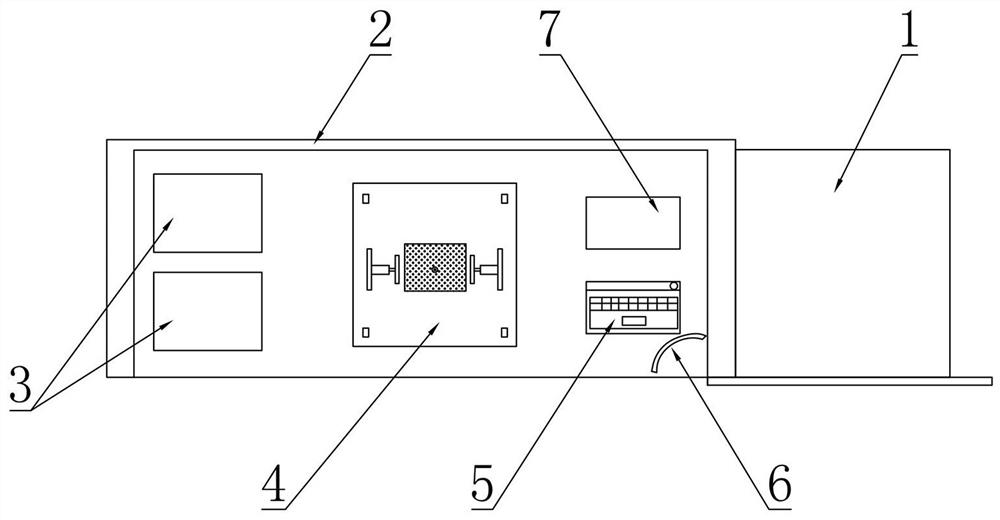

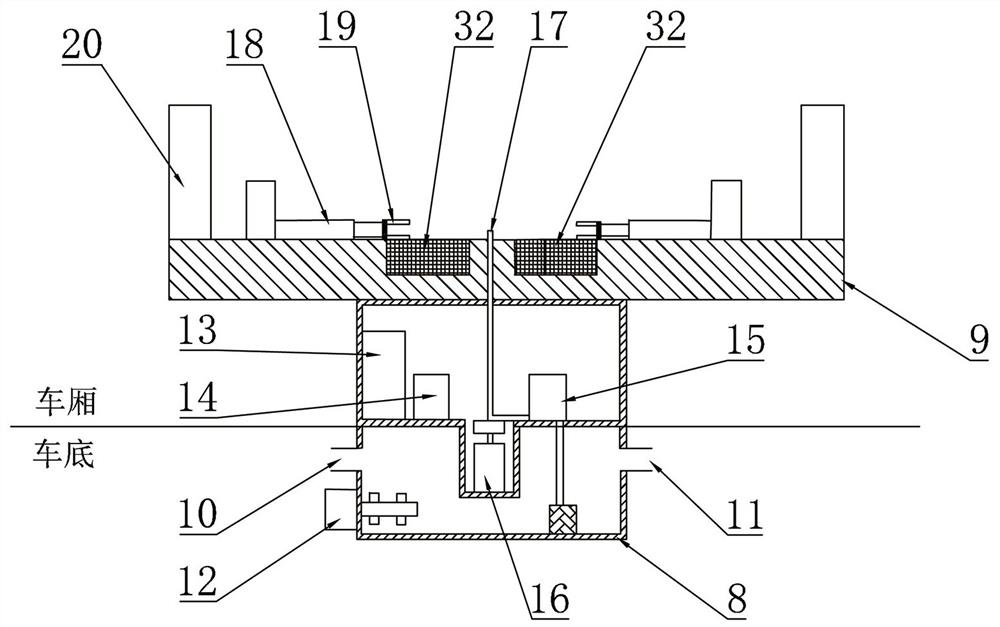

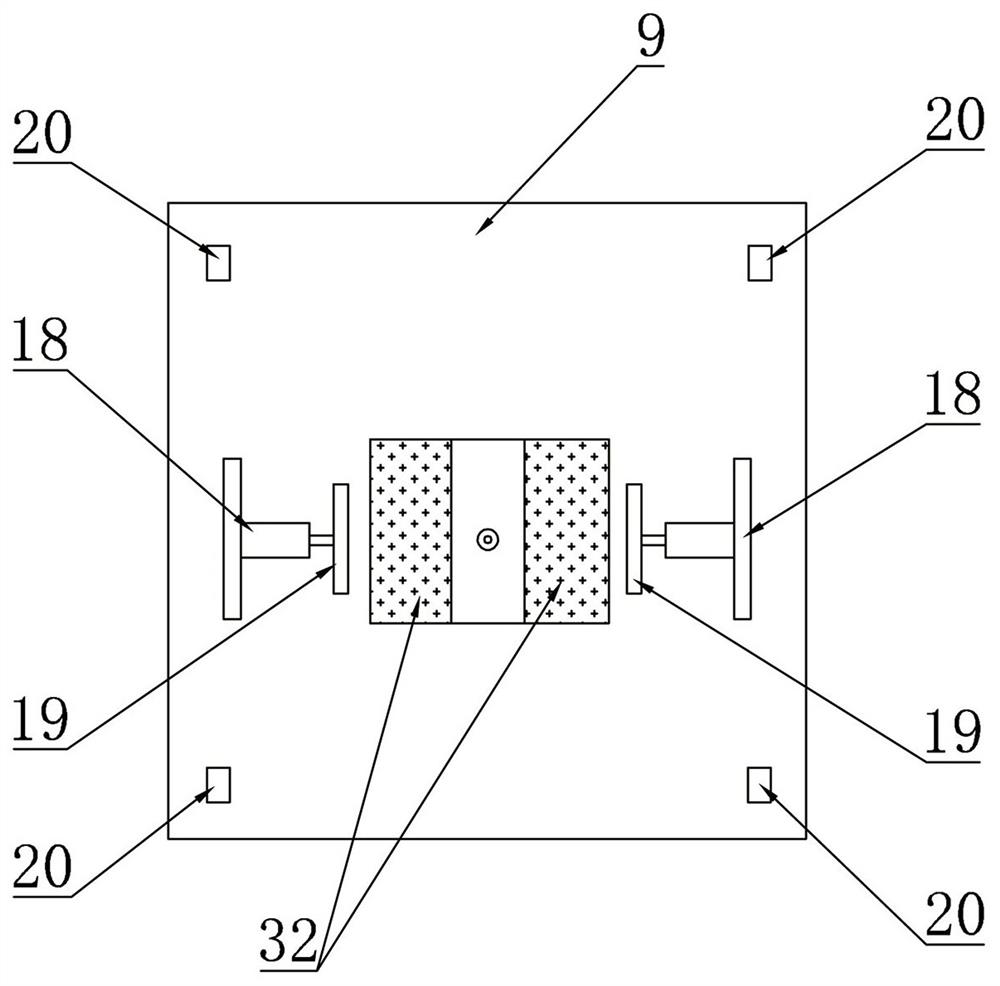

Intermediate intervention type flexible self-adaptive switching type motor stator iron core conveyor

InactiveCN113620019ARealize cooling treatmentAchieving processing powerLoading/unloadingConveyor partsPhysicsEngineering

The invention discloses an intermediate intervention type flexible self-adaptive switching type motor stator iron core conveyor which comprises a horizontal conveying mechanism, an intermediate intervention type particle passive capturing mechanism, a rapid replacement type passive collecting mechanism, a contradictory flexible positioning mechanism, a device base and a conveying supporting frame. The invention belongs to the field of motor stator iron core conveying, and particularly relates to the intermediate intervention type flexible self-adaptive switching type motor stator iron core conveyor. Aiming at the contradictory characteristics that a stator iron core needs to be in contact with dust (ensuring that the cleaning process is effective) during cleaning and cannot be in contact with the dust (enabling dust particles to be inhaled by a human body) during cleaning and collecting, under the conditions of no traditional dust removal equipment and no extra power source, omnibearing capturing and falling treatment of dust particles around a horizontal conveying mechanism are still achieved, and the technical problems that in the prior art, the dust cleaning effect needs to be guaranteed, and the dust particles cannot be diffused and inhaled by the human body during cleaning and collecting are solved.

Owner:徐州统一电机有限公司

Dust fall limestone subpackaging equipment

The invention relates to the field of limestone subpackaging, and discloses dust fall limestone subpackaging equipment. The dust fall limestone subpackaging equipment comprises a machine body. A feeding opening is formed on one side of the top end of the machine body. The two sides in the machine body are fixedly connected with isolation nets. The side, away from the machine body, of each isolation net is fixedly connected with a dust suction cover. A rotary brush is fixedly connected in each dust suction cover. The center of each rotary brush is fixedly connected with a rotating shaft. One end of each rotating shaft is fixedly connected with a fixed box located on one side of the corresponding dust suction cover. The other end of each rotating shaft is fixedly connected with a drive box located on the other side of the corresponding dust suction cover. A suction ventilator is fixedly mounted in each dust suction cover. The end, away from the corresponding rotary brush, of each suctionventilator is fixedly connected with a collection box located on the outer portion of the corresponding dust suction cover. According to the dust fall limestone subpackaging equipment, through the arrangement of the suction ventilators and the rotary brushes, the rotary brushes are driven by the drive motors to rotate, the suction ventilators are driven by driving motors to rotate, and meanwhilelimestone in the machine body is subjected to dust suction treatment.

Owner:马鞍山市如水智能科技有限公司

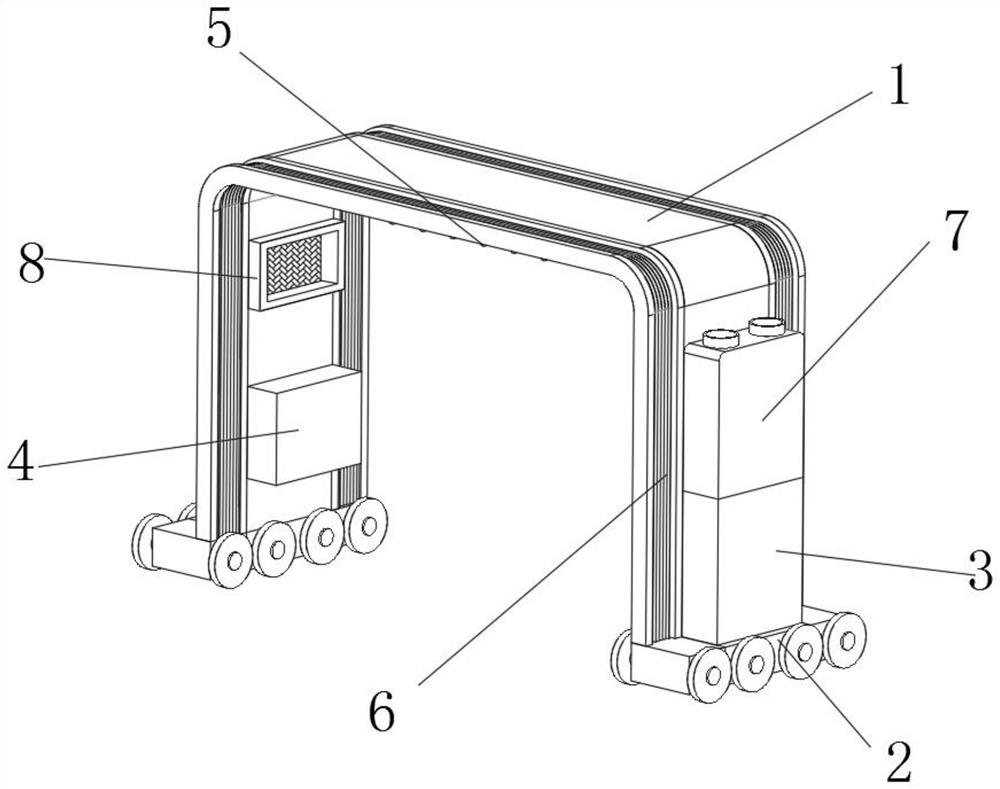

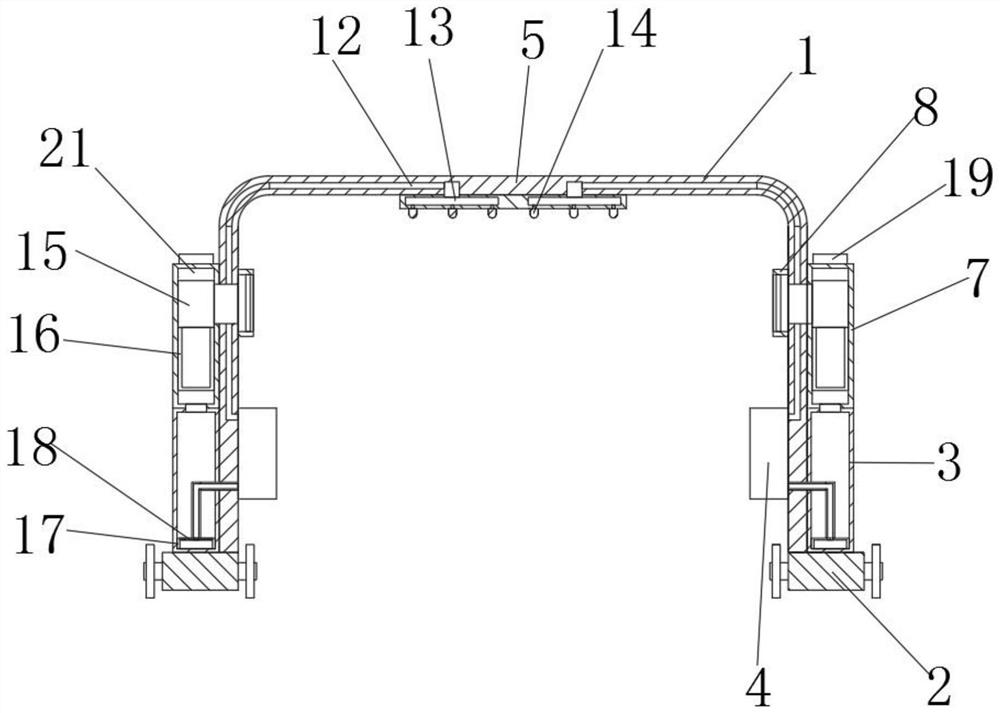

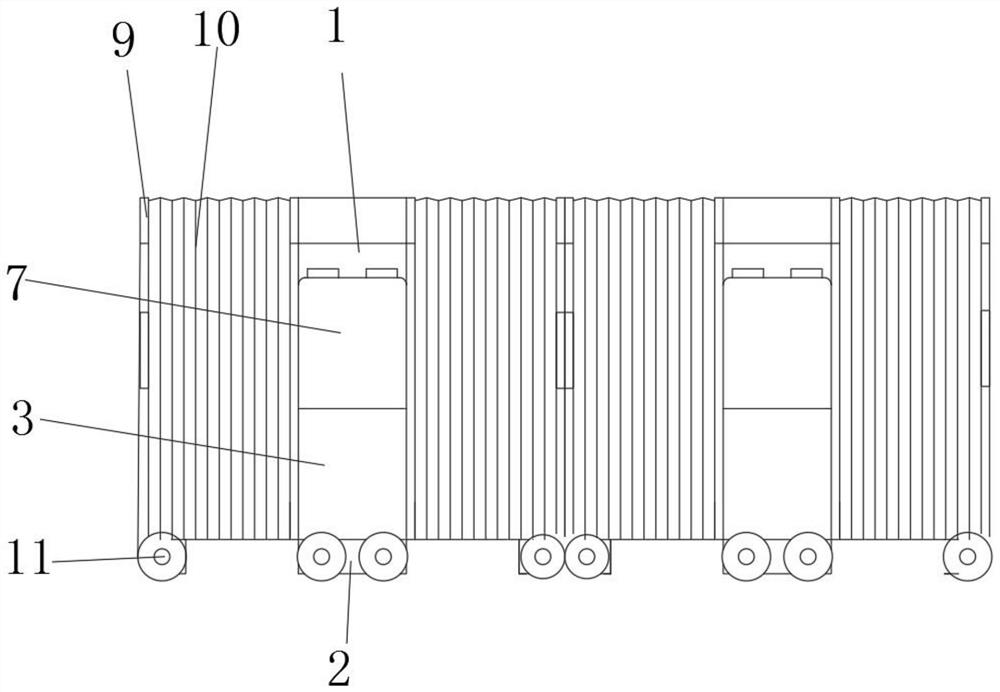

Dust falling device for highway construction

InactiveCN114307495AGuaranteed contact effectReduce wasteCombination devicesWater resourcesEngineering

The invention discloses a dust falling device for highway construction, and belongs to the technical field of highway construction auxiliary equipment.The dust falling device for highway construction comprises a support, rollers are arranged at the bottoms of the left side and the right side of the support, two spraying mechanisms and two recycling mechanisms are arranged on the support, and two extending isolation hoods are arranged on the front side and the rear side of the support in a mirror symmetry mode; the extension isolation cover comprises two frames and a folding connecting belt, the dissipation range of dust and water mist is limited through the arrangement of the support, so that the contact effect of the water mist and the dust is guaranteed, the dust falling effect is further improved, the water mist adsorbing the dust is absorbed through the arranged recycling mechanism, and the water mist is guided into the water supply tank again to be recycled after being filtered and subjected to dust falling. The waste of water resources is reduced, more energy conservation and environmental protection are achieved, dust filtered in the recycling box can avoid secondary pollution caused by dust rising after dust-containing water drops falling on the ground are evaporated, and the dust falling effect is effectively guaranteed.

Owner:刘胜林

A method of controlling building blasting dust

ActiveCN110057261BControl flyingPrevent spillageUsing liquid separation agentBlastingEnvironmental engineeringDust abatement

The invention discloses a method for controlling the blasting dust of a building. The dust is controlled by two layers of an inner air curtain and an outer air curtain. The inner air curtain mainly controls the blasting dust at first to prevent spillage. It is to carry out secondary settlement for the dust not controlled by the inner air curtain, and finally make the dust generated by the building blasting be placed in the outer air curtain to prevent it from leaking out; and put water bombs before the building blasting to form an airtight seal with the inner and outer air curtains Space, so that the relative humidity in the confined space reaches more than 95%, which is helpful for dust suppression during building blasting. Water bombs and liquid nitrogen bombs are released simultaneously and alternately after building blasting; they can quickly contact with dust and wrap on the dust surface, and at the same time, under the action of liquid nitrogen mist, the dust condenses quickly, speeding up its descent speed and ensuring dust fall Effect. The invention has fast dust removal rate, good dust removal effect and wide practicability.

Owner:XUZHOU UNIV OF TECH

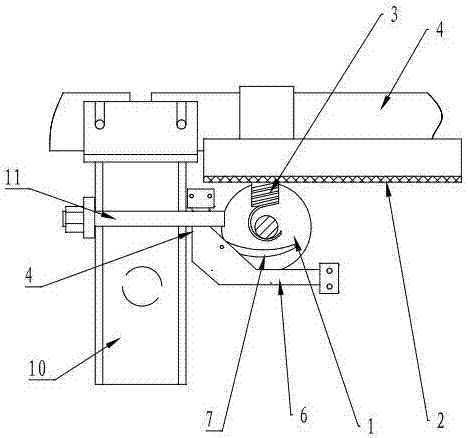

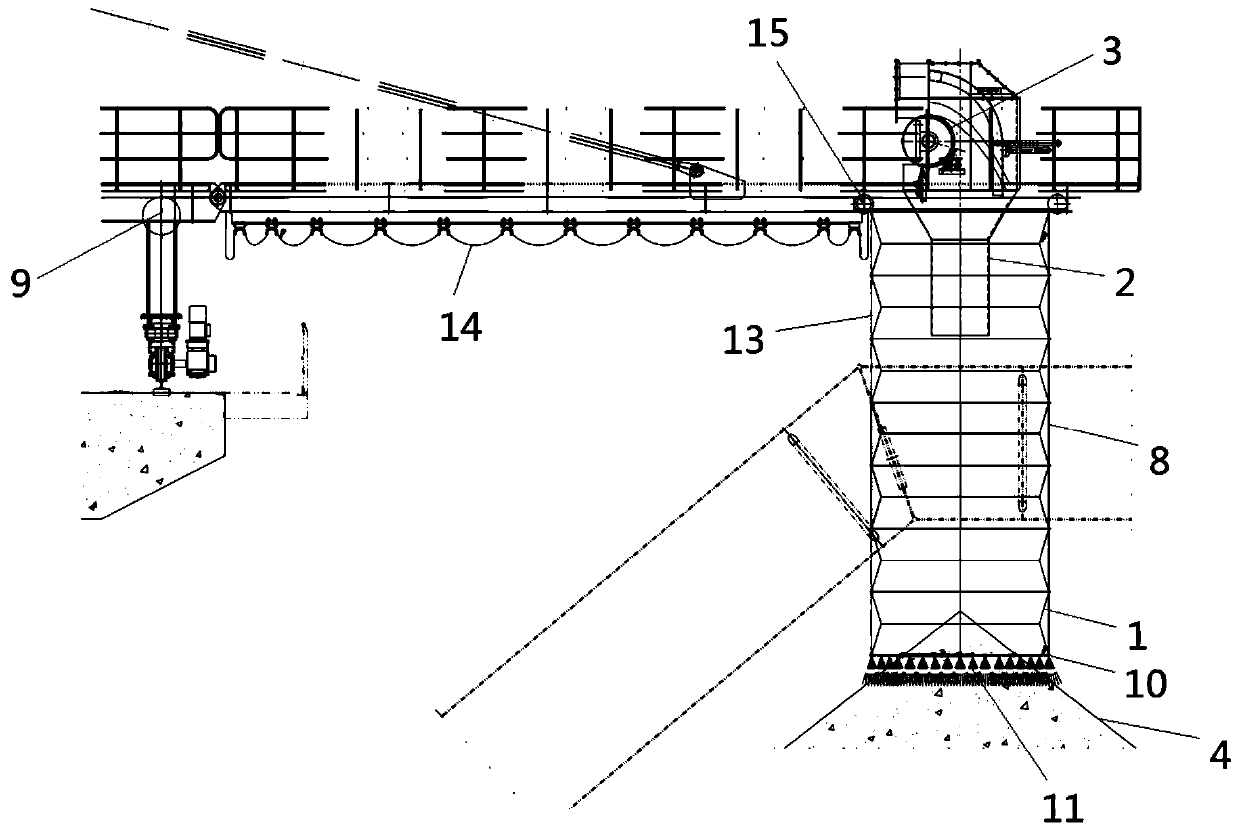

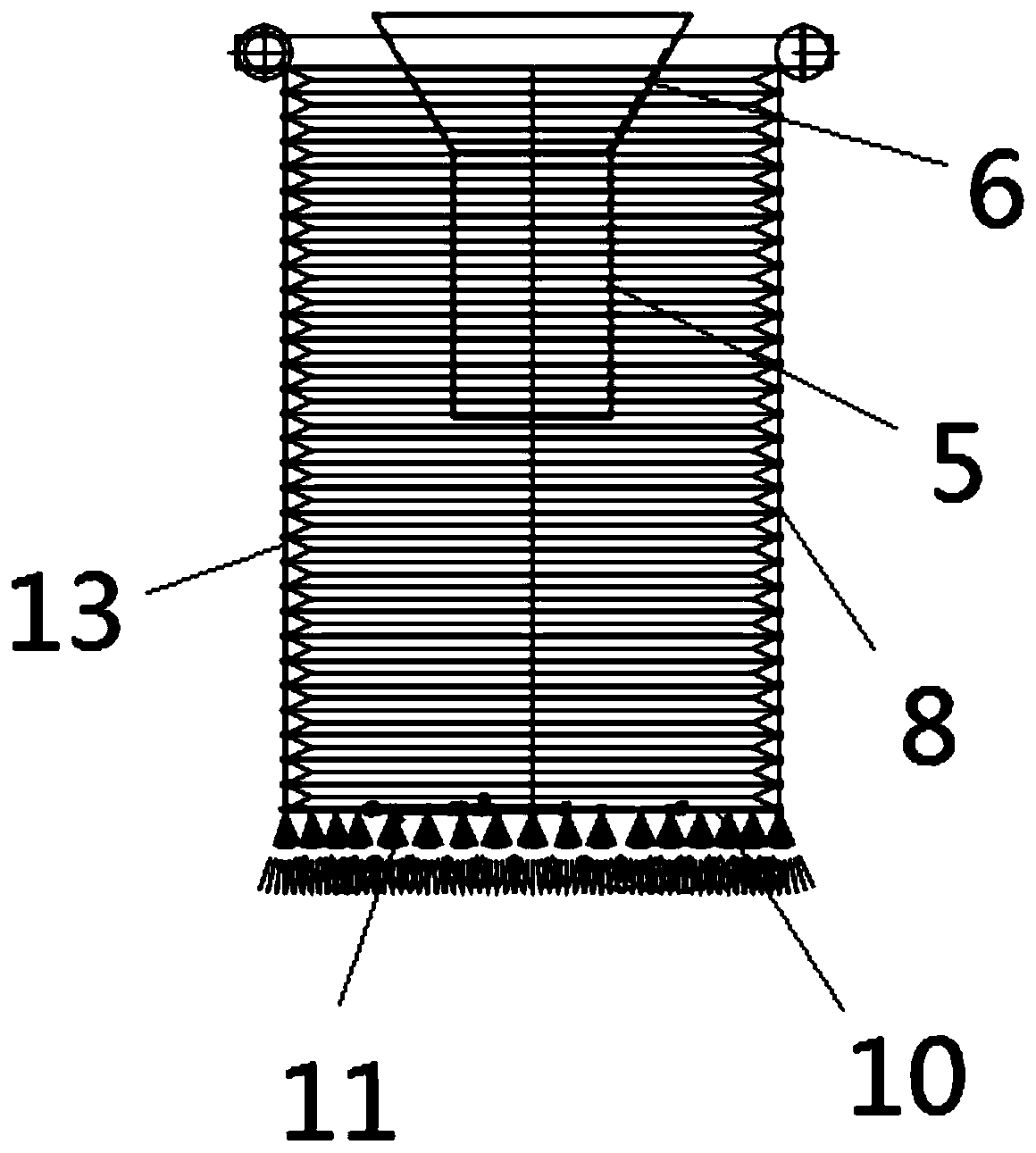

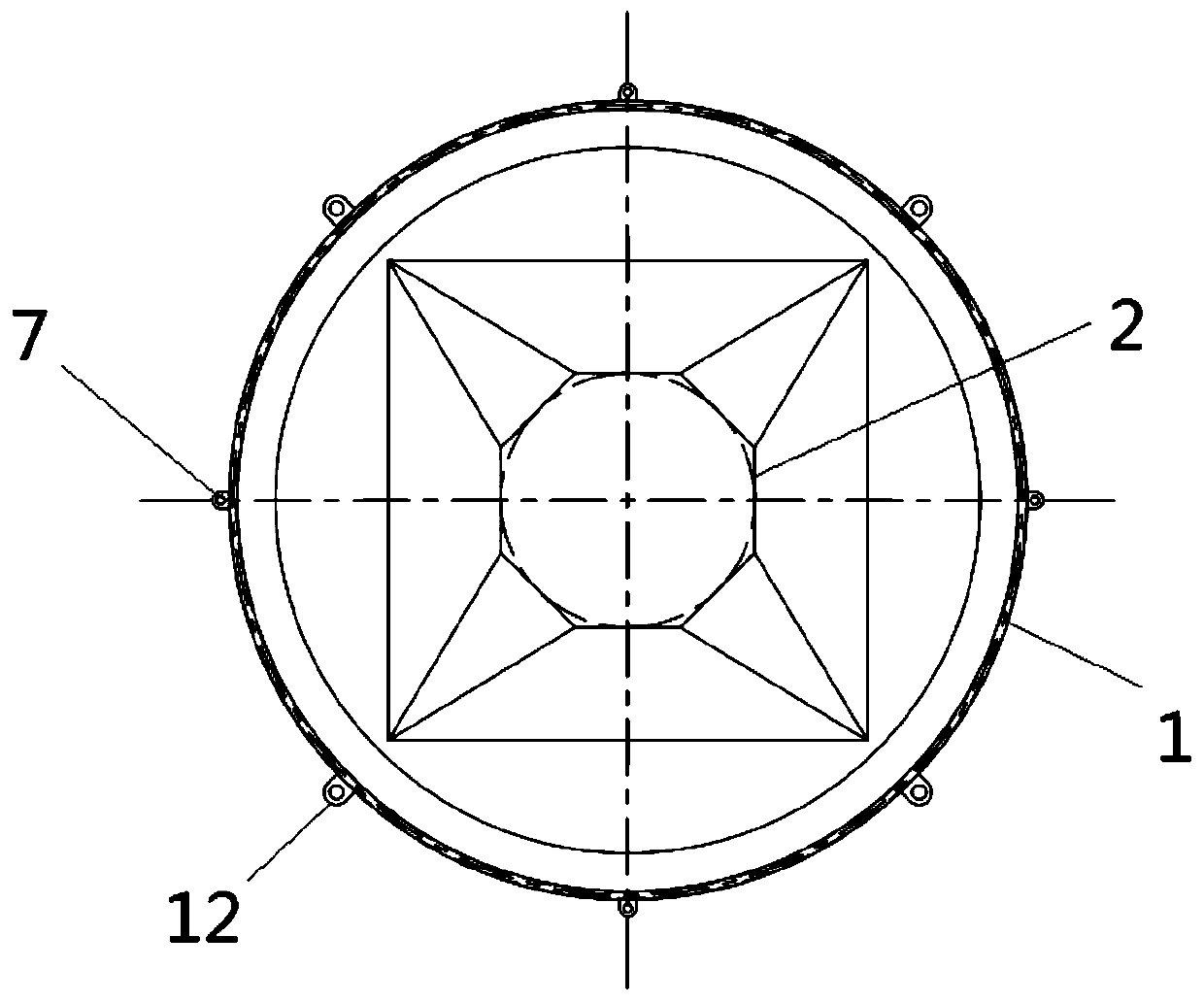

Mist-spraying and dust-falling device along belt

ActiveCN107989646AReduce labor intensityAutomate sprayingDust removalFire preventionUltimate tensile strengthConveyor belt

A mist-spraying and dust-falling device along a belt comprises a belt carrier roller. The belt carrier roller is arranged in the left-right horizontal direction, and the material conveyor belt is arranged on the upper portion of the belt carrier roller. The material conveyor belt is arranged in the front-back direction, and the lower surface of the material conveyor belt is matched with the top end of the circumferential face of the belt carrier roller. The left end and the right end of the belt carrier roller are each connected with the bottom end of a tension spring, and the two tension springs are arranged in the vertical direction. The top ends of the two tension springs are connected with a rack, and a liquid injection gun is arranged on the left side of the lower portion of the beltcarrier roller and connected with the rack in a mounted mode. According to the mist-spraying and dust-falling device along the belt, mist-spraying automation can be achieved, the disadvantage of manual operation is thoroughly overcome, the labor intensity of operators is greatly relieved, and the dust-falling effect can meet the requirement of environmental protection.

Owner:LONGKOU MINING GRP

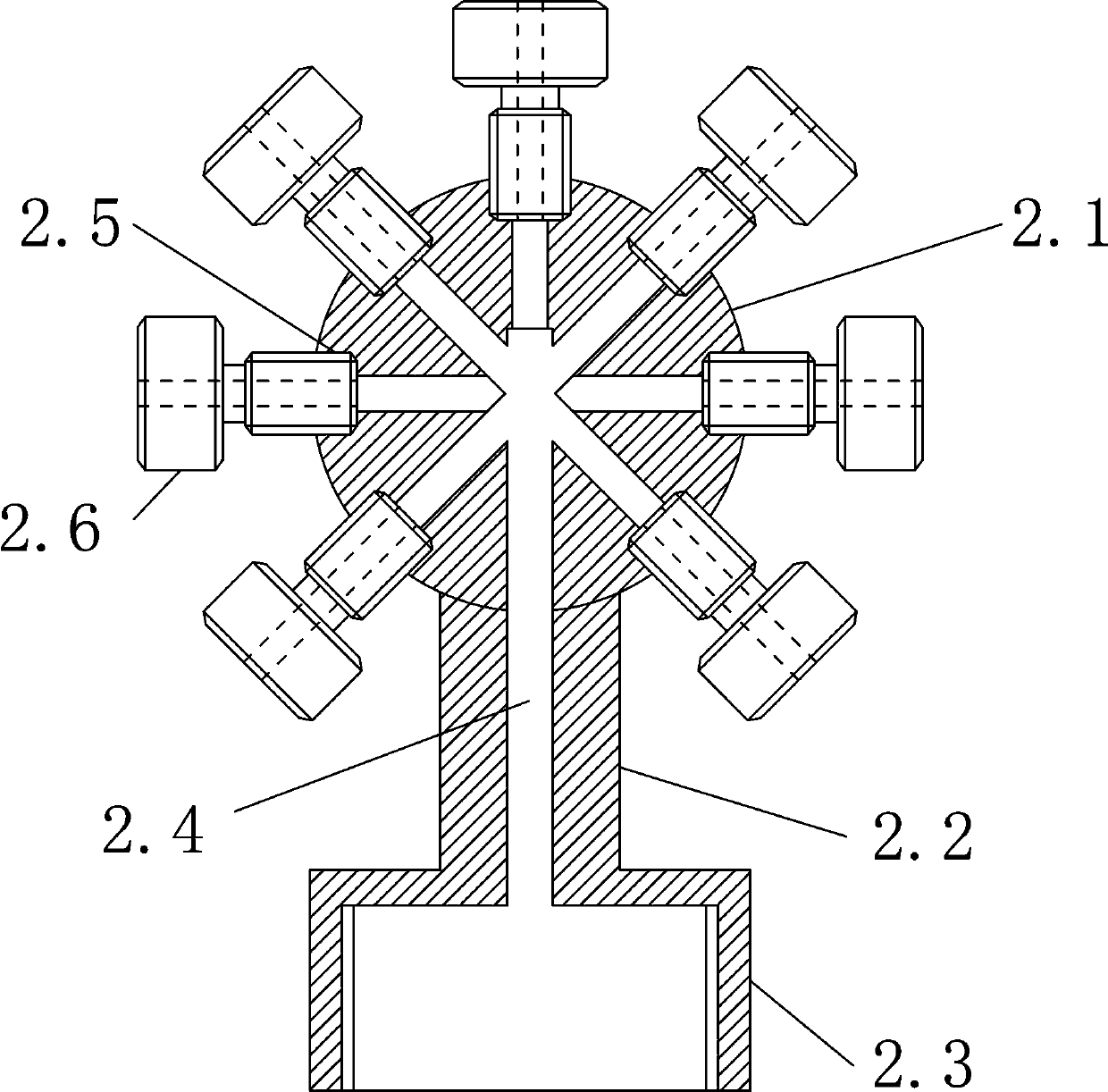

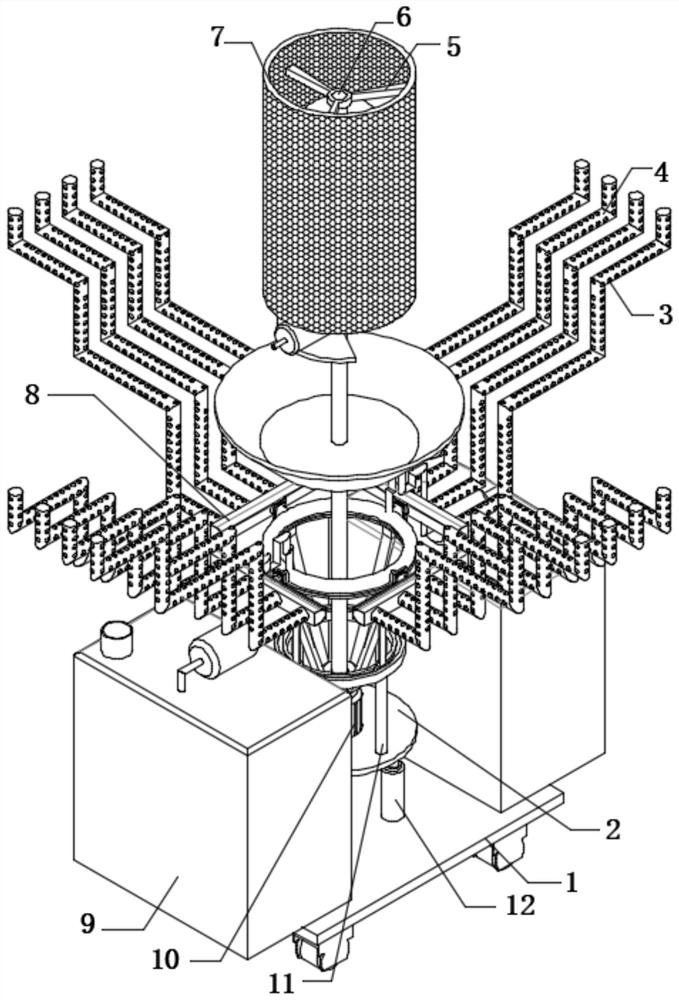

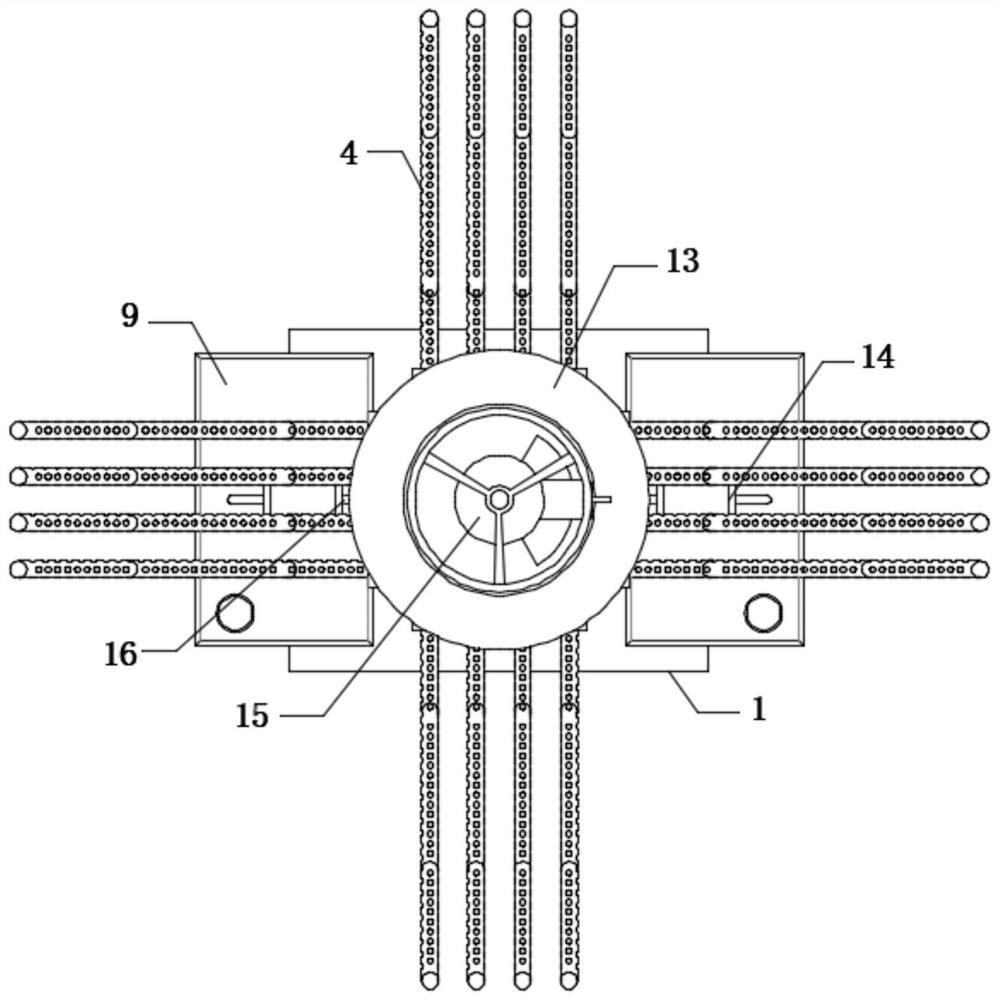

Real-time dust falling device for mineral exploitation, and operation method thereof

ActiveCN113230803ALarge coverage areaFor maximum dust reductionCombination devicesMining engineeringStructural engineering

The invention belongs to the technical field of mineral exploitation, and particularly relates to a real-time dust falling device for mineral exploitation, and an operation method thereof.The real-time dust falling device comprises a movable base and an annular water pipe, the outer wall of the annular water pipe is fixedly connected with flow dividing pipes at equal intervals, the outer wall of each flow dividing pipe is provided with a spraying assembly, and the flow dividing pipes are communicated with the annular water pipe. The spraying assembly is arranged, the spraying assembly is composed of the annular water pipe, the flow dividing pipes, a long pipe and an extending pipe, when dust falling operation is conducted on mineral exploitation, an air cylinder is adjusted to adjust the extending pipe to the proper height, then water is sprayed through spraying holes in the extending pipe, the extending pipe is in a step shape, and the spraying holes are annularly distributed in the outer wall of the extending pipe, so that when water is sprayed, the water is sprayed out from the spraying holes at different angles to form independent coverage surfaces which are diffused outwards, the coverage area of the water is expanded to the maximum, and maximum dust falling is realized.

Owner:石台县创亿矿业有限公司

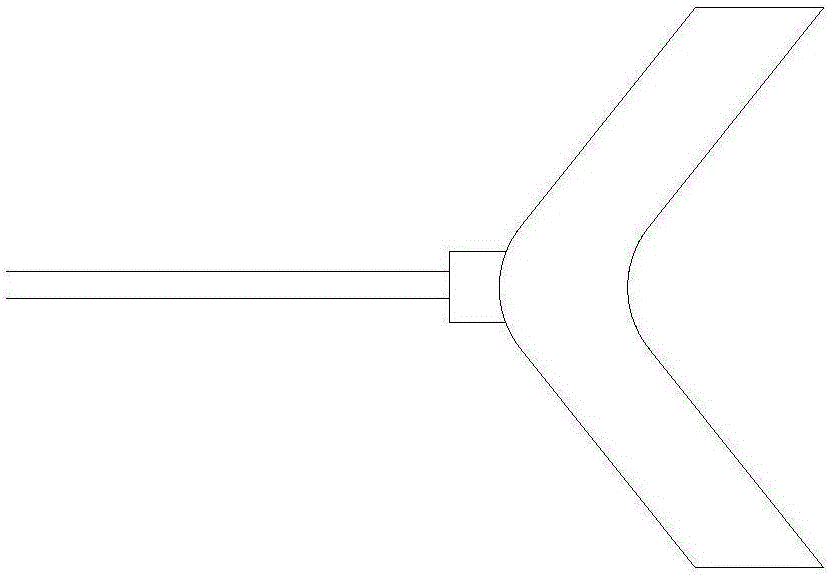

Storage field dust suppression device

The invention relates to the technical field of stockyard dust removal, in particular to a storage field dust suppression device. The device comprises: a flexible cover body having a feed port and a discharge port, the discharge port extending to a predetermined distance above a material pile; and a beam structure arranged at the feed port and provided with a rectification section which extends towards the discharge port so as to enable materials to vertically fall, wherein the inner diameter of the rectification section is smaller than that of the feed port. The storage field dust suppressiondevice can effectively reduce dust during falling of the materials.

Owner:HUADIAN HEAVY IND CO LTD

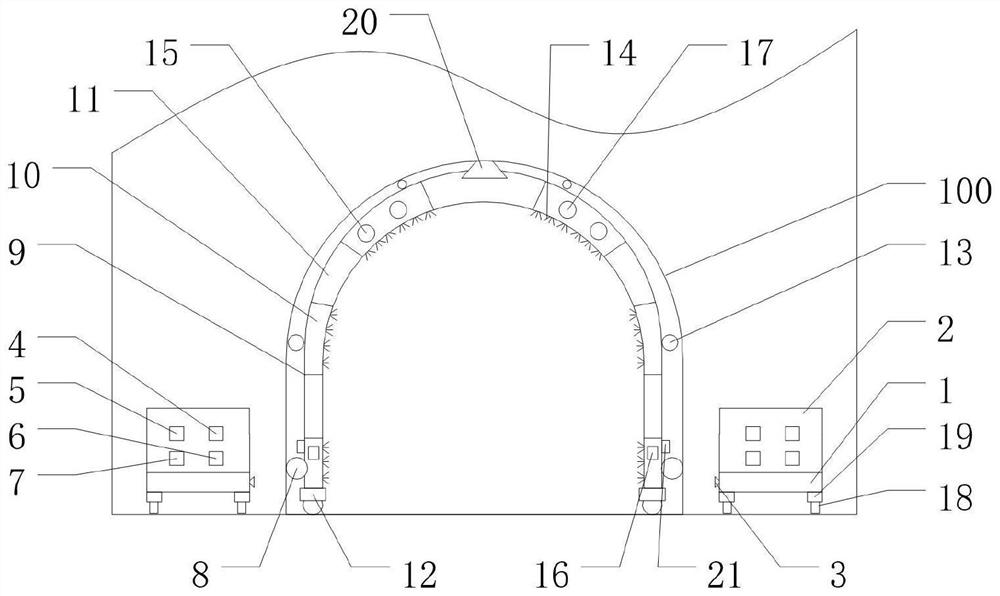

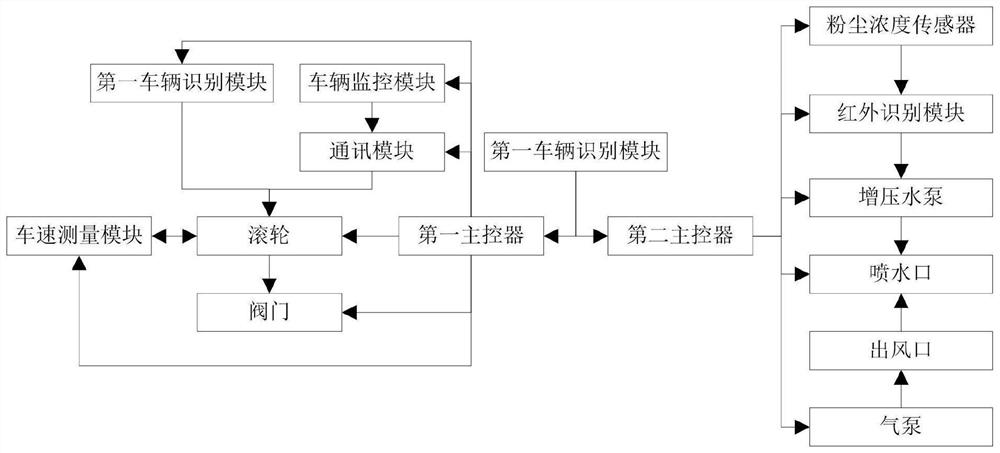

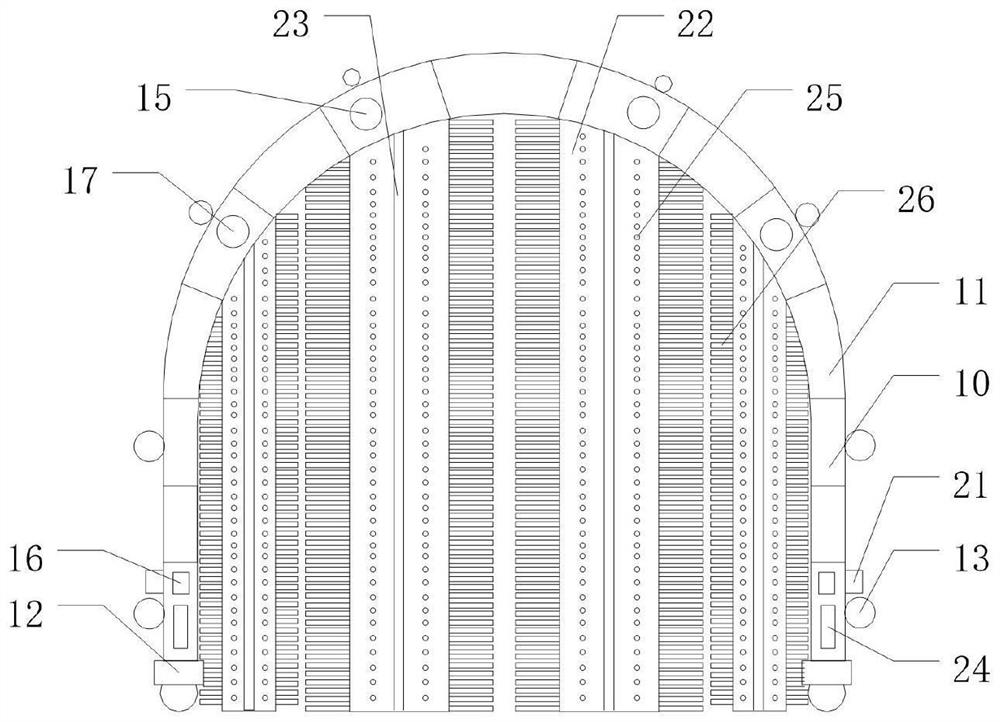

Tunnel construction dust monitoring and automatic water spraying system

InactiveCN112814727AReduce pollutionReduce personal injuryDust removalFire preventionSpray nozzleMaster controller

The invention discloses a tunnel construction dust monitoring and automatic water spraying system. The system comprises an outside-tunnel dust falling mechanism and an in-tunnel dust falling mechanism; the outside-tunnel dust falling mechanism comprises a dust falling trolley and a vehicle monitoring module; the dust falling trolley comprises a bracket, a water tank, a spraying nozzle and a first intelligent control mechanism; the first intelligent control mechanism comprises a first vehicle recognition module, a communication module, a vehicle speed measurement module and a first master controller; the in-tunnel dust falling mechanism comprises a water conveying pipe and a plurality of arched dust falling mechanisms; each arched dust falling mechanism comprises an extension rod, an elastic arc-shaped air bag and a base; a second intelligent control mechanism is further arranged on each arched dust falling mechanism; and each second intelligent control mechanism comprises a second master controller, a plurality of infrared recognition modules, a booster water pump and a dust concentration sensor. According to the tunnel construction dust monitoring and automatic water spraying system, through the arrangement of the outside-tunnel dust falling mechanism and the in-tunnel dust falling mechanism, flexible dust falling of dust caused by vehicle passing of the to-be-constructed tunnel can be achieved, the dust falling effect is improved, and use of labor force is reduced.

Owner:天威英利

Dust removal system based on mine cooling system

The invention aims to overcome the shortcomings of the prior art, and provides a dust removal system based on a mine cooling system, and the dust removal system is lower in investment and operating cost, and can guarantee the cooling effect and the dust removal effect at the same time. The dust removal system includes a plurality of dust removal water pipes which are arranged at an upper wall of a dust removal passage and longitudinally extend along the dust removal passage. The dust removal water pipes are respectively provided with dust removal nozzles. A dust removal steel rail is paved on the bottom wall of the dust removal passage. The dust removal steel rail comprises a walking plate and a lower base plate. A separator plate is disposed between the walking plate and the lower base plate. A dust pushing chamber and a dust collecting chamber are formed by separation of the separator plate. An installing plate is disposed in the dust pushing chamber. An elevating cylinder is disposed under the installing plate. A dust pushing oil cylinder and a V-shaped pushing head are disposed on the installing plate. The walking plate is provided with a dust leaking port. A depressed part of the pushing head is opposite to the dust leaking port and used for pushing dust on the walking plate into the dust leaking port. The walking plate is provided with an opening door corresponding to the installing plate for allowing the installing plate and the dust pushing oil cylinder and the pushing head on the installing plate to rise over the walking plate.

Owner:CHONGQING HEQU JIUFENG COAL CO LTD

Environment-friendly construction structure and construction method for green dust fall of road

PendingCN114352119AEnsure normal dust suppression effectEnvironmentally friendly and dust-reducing effectUsing liquid separation agentFencingArchitectural engineeringStructural engineering

The invention discloses an environment-friendly road dust falling construction structure and a construction method in the technical field of construction dust falling, a supporting seat is characterized in that two lifting openings are formed in the bottom side of the supporting seat, lifting frames are fixedly connected to the upper sides of the lifting openings, lifting rods are slidably connected to the interiors of the lifting openings, clamping openings are formed in the two sides of the lifting frames correspondingly, and the clamping openings are fixedly connected with the lifting rods; a clamping block is slidably connected into the clamping opening, a clamping mechanism for controlling the clamping block to move is arranged on the bottom side of the supporting seat, a supporting plate is rotatably connected to the bottom of the lifting rod, a control mechanism for controlling the working mode of the supporting plate is arranged on the outer side of the supporting seat, and a dust falling mechanism is arranged on the upper side of the supporting seat. The dust at the tail of the large engineering vehicle is subjected to targeted tracking and dust falling, on the premise that the normal dust falling effect is guaranteed, the situation that a large amount of dust surged by the large vehicle is generated in a short time and breaks through the dust falling range of the whole device is avoided, and the environment-friendly dust falling effect is good.

Owner:WEIFANG CHANGDA CONSTR GROUP

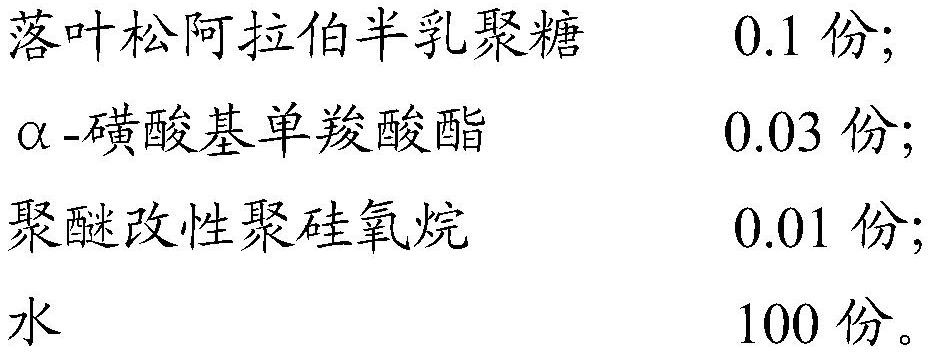

A kind of spray dust suppression agent and its preparation method and application

ActiveCN112516713BReduce surface tensionReduce pollutionUsing liquid separation agentAtmospheric dustActive agent

The application belongs to the technical field of atmospheric dust pollution control, and in particular relates to a spray dust suppressant and its preparation method and application. The application provides a spray dust suppressant, which includes: 0.1-0.3 parts of coagulant; 0.02-0.06 parts of surfactant; 0.01-0.06 parts of defoamer; 100 part of water; the spray dust suppressant forms water mist with a particle size of 30-150 μm through atomization. The application provides a method for preparing a spray dust suppressant, comprising: mixing a coagulant, a surfactant, a defoamer and water to prepare a spray dust suppressant. The application provides a spray dust suppressant and its preparation method and application, which can effectively solve the traditional technical defect in the prior art that it is difficult to settle atmospheric dust particles below PM5.0 only by atomized water.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Unmanned aerial vehicle automatic replenishment station and unmanned aerial vehicle intelligent dust falling system applied by same

PendingCN113184183AReduce wasteStrong targetingRotary stirring mixersUsing liquid separation agentUncrewed vehicleElectric devices

The invention discloses an unmanned aerial vehicle automatic replenishment station and an unmanned aerial vehicle intelligent dust falling system applied thereof. The unmanned aerial vehicle automatic replenishment station comprises a replenishment unit used for conducting automatic replenishment on an unmanned aerial vehicle, a ground general control unit used for controlling and deploying the unmanned aerial vehicle and all devices in the unmanned aerial vehicle automatic replenishment station, a parking apron which is used for parking the unmanned aerial vehicle, and a power supply unit which is used for supplying power to all electric devices. The unmanned aerial vehicle intelligent dust falling system comprises the unmanned aerial vehicle automatic replenishment station and at least one unmanned aerial vehicle module matching the unmanned aerial vehicle automatic replenishment station to work. And each unmanned aerial vehicle module is internally provided with a dust suppressant spraying assembly, an information acquisition assembly and a vehicle body control assembly. The unmanned aerial vehicle intelligent dust falling system is high in intelligent degree, good in use simplicity and convenience, low in dust suppression cost and capable of accurately and efficiently performing dust suppression treatment on a construction site. The unmanned aerial vehicle intelligent dust falling system is suitable for being used for treating construction dust on a building construction site.

Owner:XIAN UNIV OF SCI & TECH

An automatic dust suppression system and method at the coal unloading point of the lifting shaft

ActiveCN110951512BQuickly meet the needs of purificationEmissions are strictly controlledGaseous fuelsDust controlEnvironmental engineering

Owner:徐州宇晟安全环保科技有限公司 +1

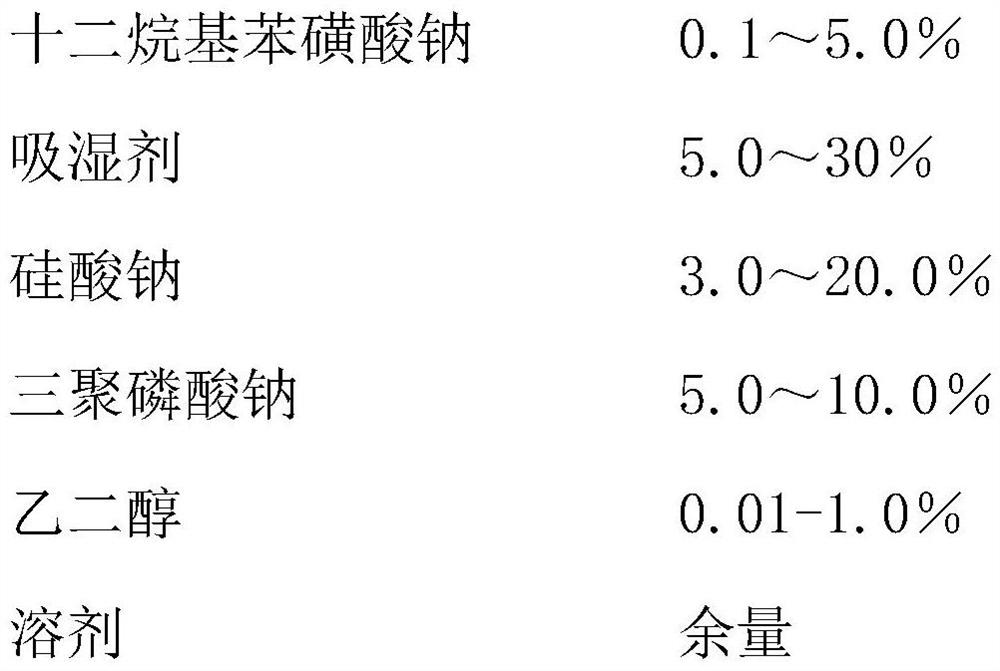

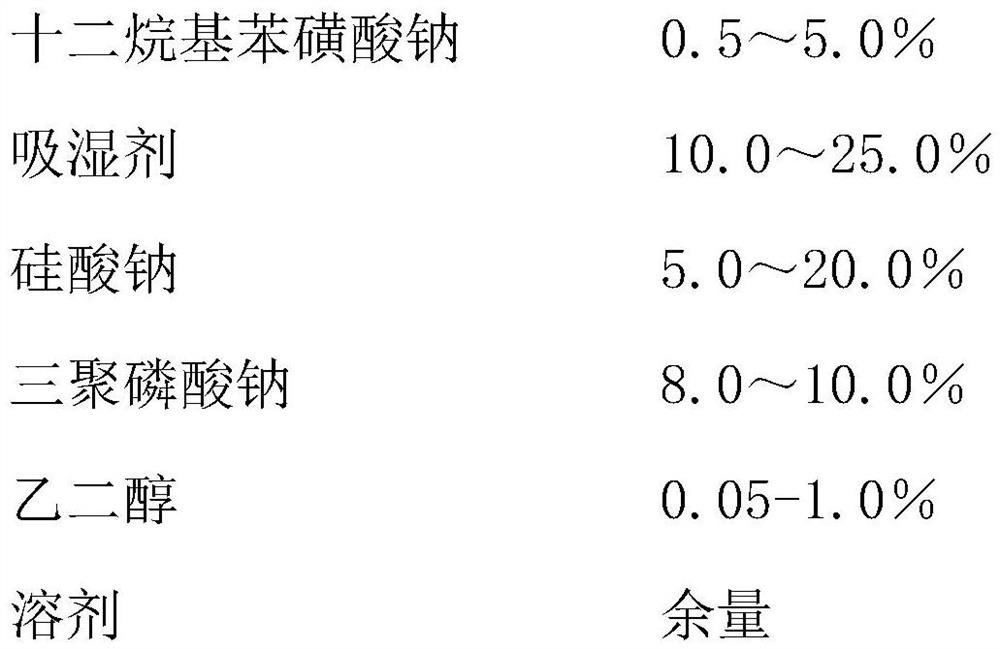

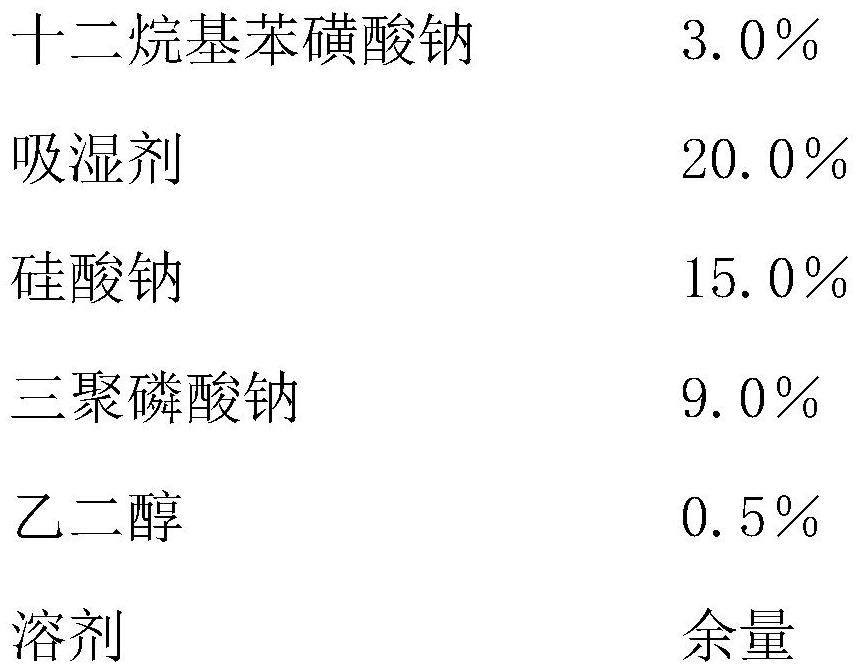

Efficient environment-friendly dust suppressant and preparation method thereof

InactiveCN111662680ASimple componentsGood effectOther chemical processesSodium silicateSodium triphosphate

The invention discloses an efficient environment-friendly dust suppressant, which comprises the following components in parts by weight: sodium dodecyl benzene sulfonate, a moisture absorbent, sodiumsilicate, sodium tripolyphosphate, ethylene glycol and a solvent. The invention provides an efficient environment-friendly dust suppressant, which has the advantages of simple components, good effect,strong wetting and water absorption effects, strong freezing resistance, complexing adsorption of heavy metal ions and the like, can adapt to different environments in different regions, reduces thecontent of heavy metals in air, reduces air pollution, ensures the long-time dust suppression effect, is free of pollution, and has good economic benefits.

Owner:江苏乐尔环境科技股份有限公司

An intelligent road sweeper and its identification method and control method for road pollutants

The invention discloses an intelligent road sweeper and its road pollutant identification method and control method. The road sweeper includes: a road sweeper body, a laser radar, a camera, an encoder, a dust concentration detector, an inertial sensor, and a GPS system and handle the controller. The road pollutant identification method includes: obtaining the RGB image of the clean road surface and road facilities to be cleaned, converting the acquired RGB image into HSV space, and obtaining a BP neural network model that can identify the clean road surface and road facilities; The real-time image information of the road is input to the BP neural network model to identify pollutants. The method for identifying pollutants such as garbage in the present invention utilizes the HSV feature of the road image, which has a larger amount of information than the gray value of the image alone, and the effect of identifying pollutants such as garbage is better.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com