Dust suppressant, preparation method and application

A technology of dust suppressant and additive, which is applied in the direction of chemical instruments and methods, dust prevention, mining equipment, etc. It can solve the problems that tiny dust cannot be adsorbed and agglomerated, adverse effects of the surrounding environment, and unsatisfactory dust suppression effect, etc., so as to promote Film formation of dust suppressant, prolonged dust suppression time, and long dust suppression cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16

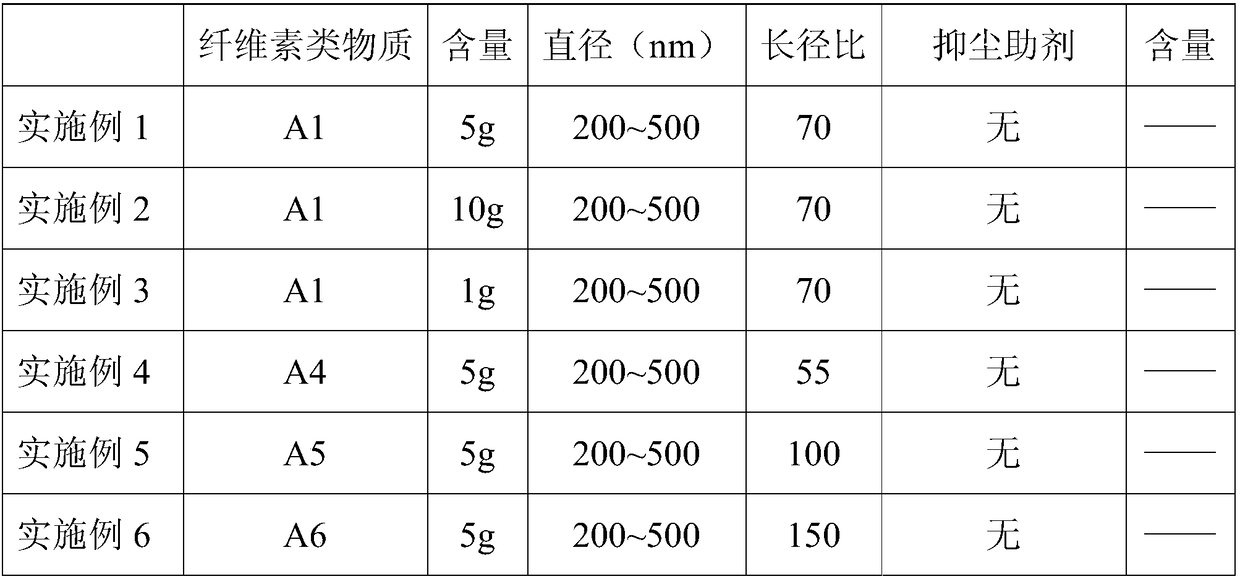

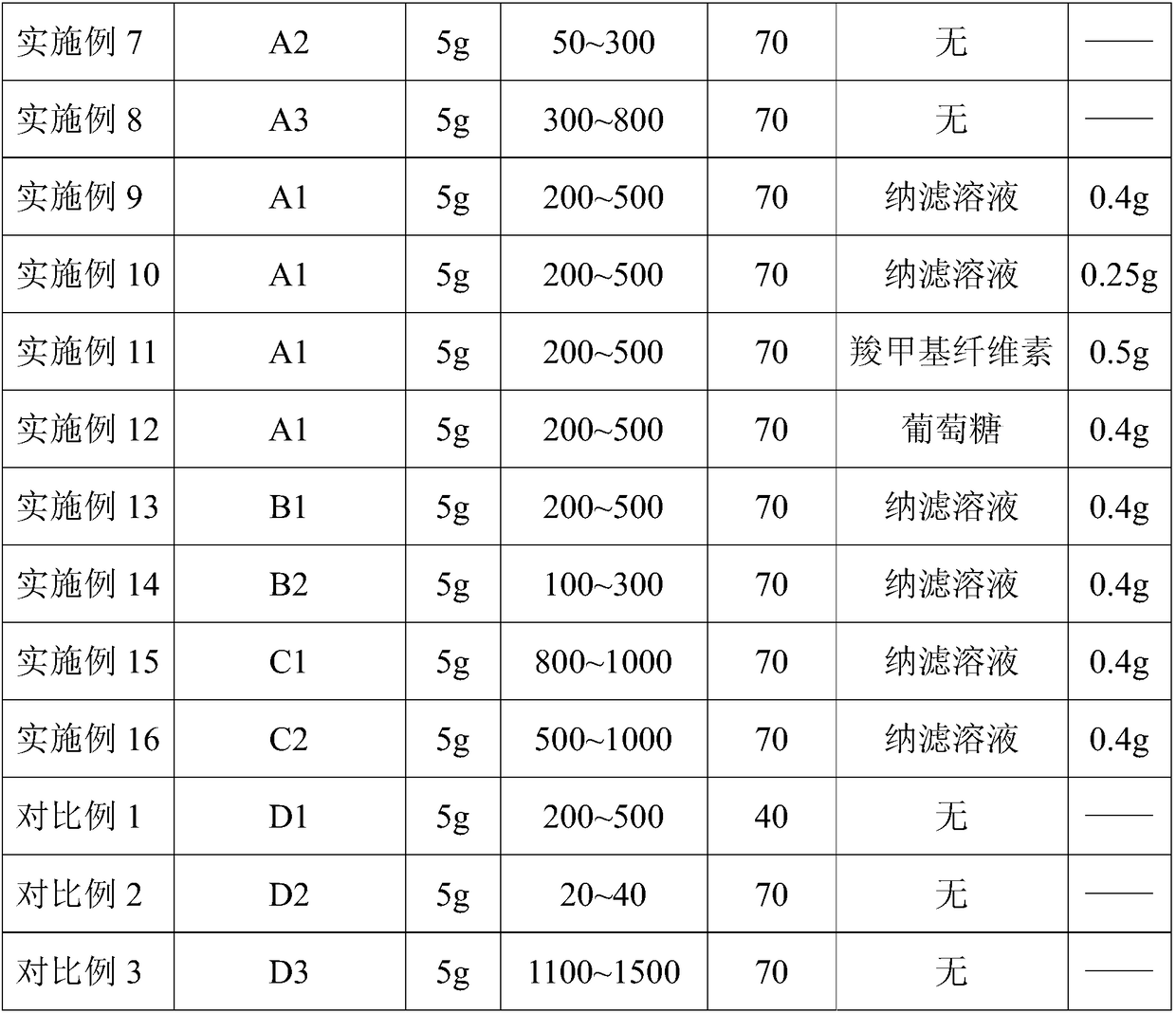

[0080] A preparation method of dust suppressant, comprising the steps of:

[0081] Mix the cellulose material and the dispersion liquid of the dust suppression auxiliary agent according to the formula amount in Table 1, and obtain 100 g of the dust suppression agent after ultrasonic dispersion.

[0082]

[0083]

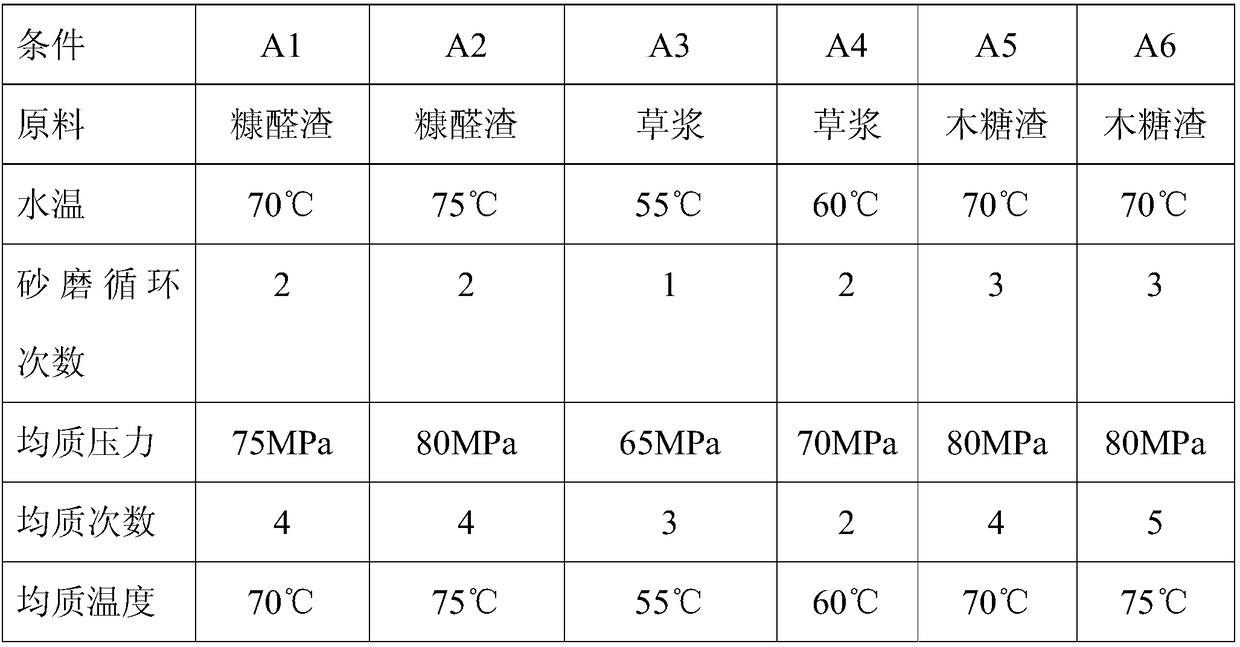

[0084] A1, A2, A3, A4, A5 and A6 are all micronano lignocellulose, the lignin content in A1 and A2 is 25wt% respectively, the lignin content in A3 and A4 is 13wt%, and the lignin content in A5 and A6 The content is 37wt%. B1 and B2 are nanocellulose with a cellulose content of 99 wt%. C1 and C2 are micro-nano cellulose with a cellulose content of 99 wt%. D1 is micro-nano cellulose, the cellulose content is 99wt%, and the aspect ratio is 40. D2 is micro-nano cellulose with a cellulose content of 99 wt% and an aspect ratio of 70. D3 is micro-nano cellulose with a cellulose content of 99 wt% and an aspect ratio of 70.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com