Cylinder inside and outside cold water mixed double injection type diesel engine structure

A diesel engine, cold water technology, applied in the direction of internal combustion piston engine, mechanical equipment, engine components, etc., can solve the problems of limiting the thermal efficiency and power liter of diesel engines, and achieve the goal of reducing temperature, improving fuel economy and emission characteristics, and reducing NOx emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

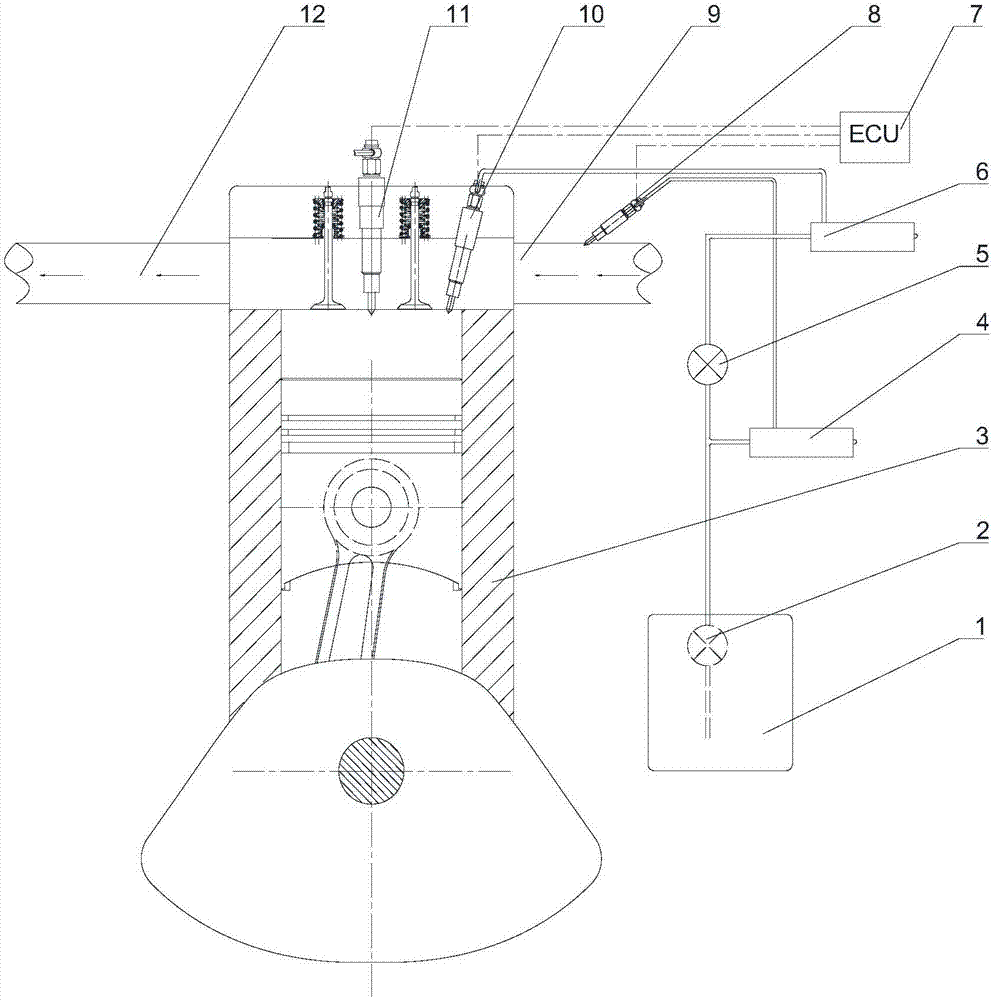

[0031] Such as figure 1 As shown, a diesel engine structure with internal and external cold water mixing dual injection includes a diesel engine body 3, an intake manifold 9 and an exhaust manifold 12 arranged on the diesel engine body 3, a fuel injector 11, and a diesel engine body 3. The in-cylinder sprinkler 10, the high-pressure water pump unit connected with the in-cylinder sprinkler 10, the external sprinkler 8 arranged in the intake manifold 9, the low-pressure water pump connected with the external sprinkler 8 unit, an electronic controller 7 electrically connected to the fuel injector 11, the in-cylinder water sprayer 10, the high-pressure water pump unit, the external cylinder water sprayer 8 and the low-pressure water pump unit respectively. The crankshaft of the diesel engine is provided with a rotational speed sensor electrically connected with the electronic controller 7 . In the working state, the rotational speed sensor can monitor the rotational speed of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com