Water kinetic energy type filler-free cooling tower

A technology with hydrokinetic energy and no filler, applied in the field of cooling tower, can solve the problems of difficult to maintain cooling efficiency of cooling tower, high operation and maintenance cost, easy fouling of filler, etc., achieve high water removal efficiency, improve unstable factors, ventilation resistance small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

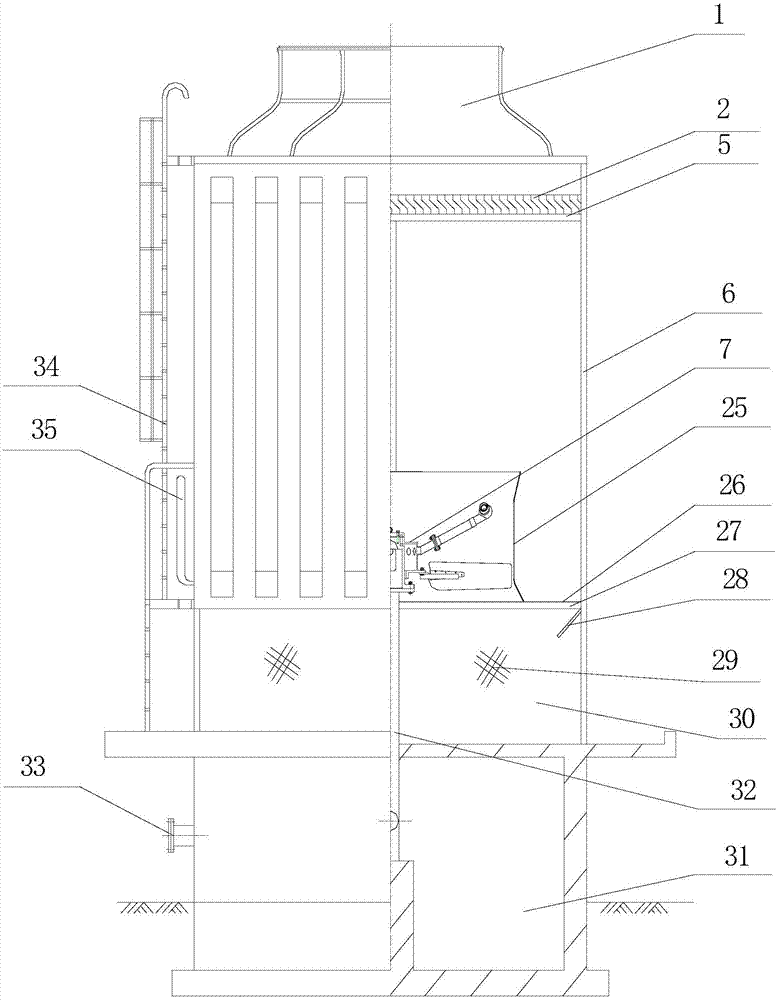

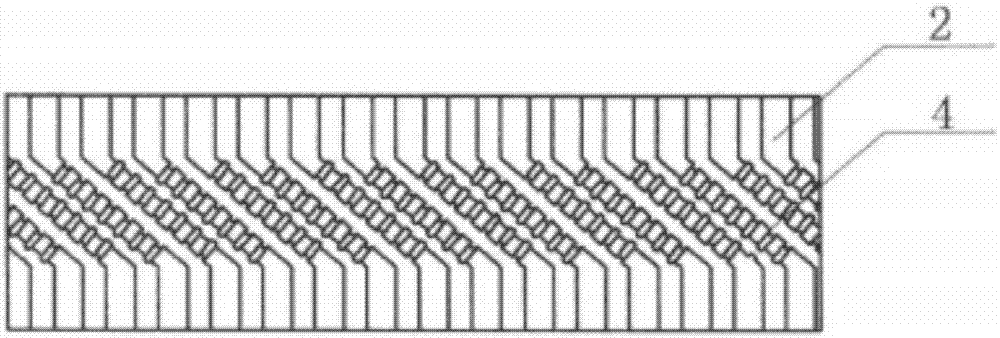

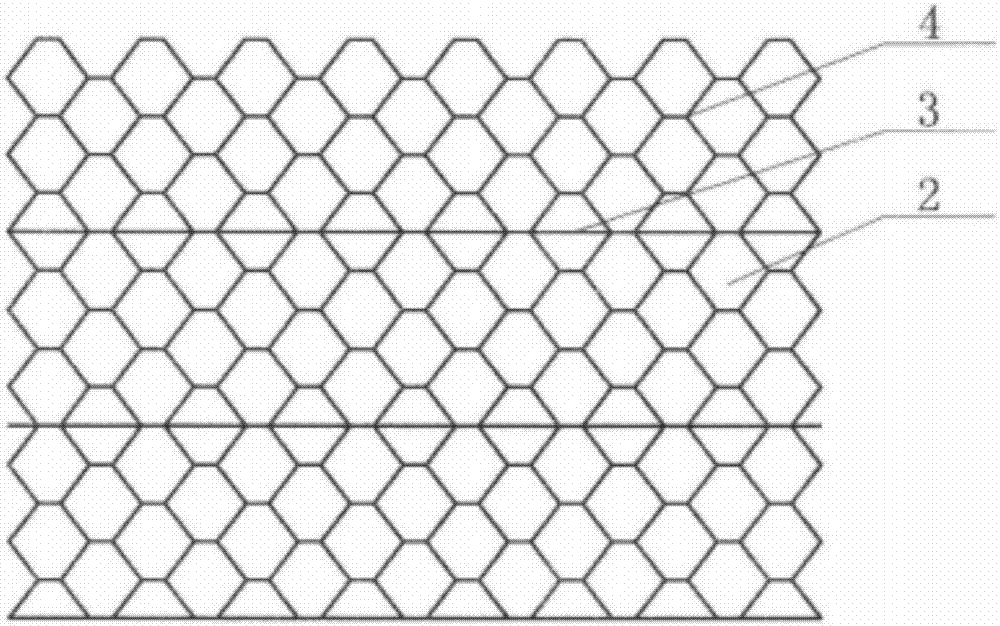

[0032] Such as Figure 1-9 As shown, the hydrokinetic energy cooling tower without filler includes: air duct 1, multi-dimensional water collector 2, tower body 6, hydrokinetic jet device assembly 7, volute jet 18, air collecting duct 25, and water spray grid Plate 26, sump 31; air cylinder 1 is located at the top of the tower; multi-dimensional water collector 2 is located below the tower top air cylinder 1, evenly covering the plane of the entire multi-dimensional water collector frame 5, and fixed on the multi-dimensional water collector frame 5, the multi-dimensional water collector 2 is bonded into a hexagonal honeycomb structure by the multi-dimensional sheet 4 and the straight sheet 3; The outer surface is covered with a glass fiber reinforced plastic panel, and the space between the multi-dimensional water collector 2 and the hydraulic kinetic energy ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap