Corrosion resistance experiment method of metal corrugated pipe

A metal bellows, corrosion resistance technology, applied in the field of metal bellows corrosion resistance experiments, can solve the problems of large errors, inability to reproduce local corrosion effects well, long monitoring period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

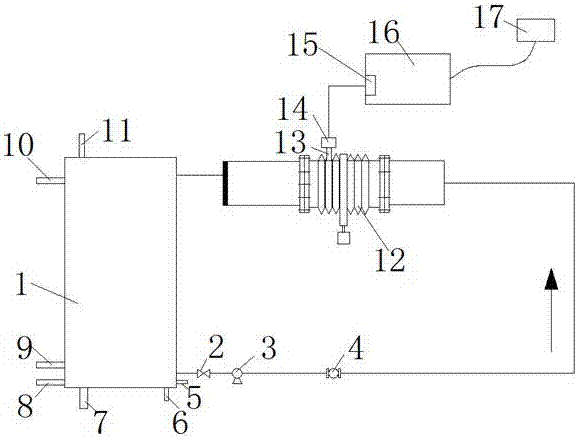

[0025] In order to further understand the technical content, features and effects of the present invention, the following examples are listed, and detailed descriptions are given below in conjunction with the drawings.

[0026] Such as figure 1 As shown, a metal bellows corrosion resistance test method is based on a set of equipment, which includes pipelines, corrosion-resistant storage tanks 1, corrosion-resistant pumps 3, ball valves 2, electromagnetic flow meters 4, thermometers 5, and pH meters 6 , Dissolved oxygen meter 7, a test metal bellows 12 is connected in series on the pipeline;

[0027] A monitoring device is provided on the metal bellows 12 to monitor the corrosion in the metal bellows 12 in real time. The monitoring device includes a signal acquisition module 14, a signal transmission device, an A / D converter 15, a data analysis module 16, and data management. The signal acquisition module 14 includes a three-electrode monitoring probe, a signal generation control u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com