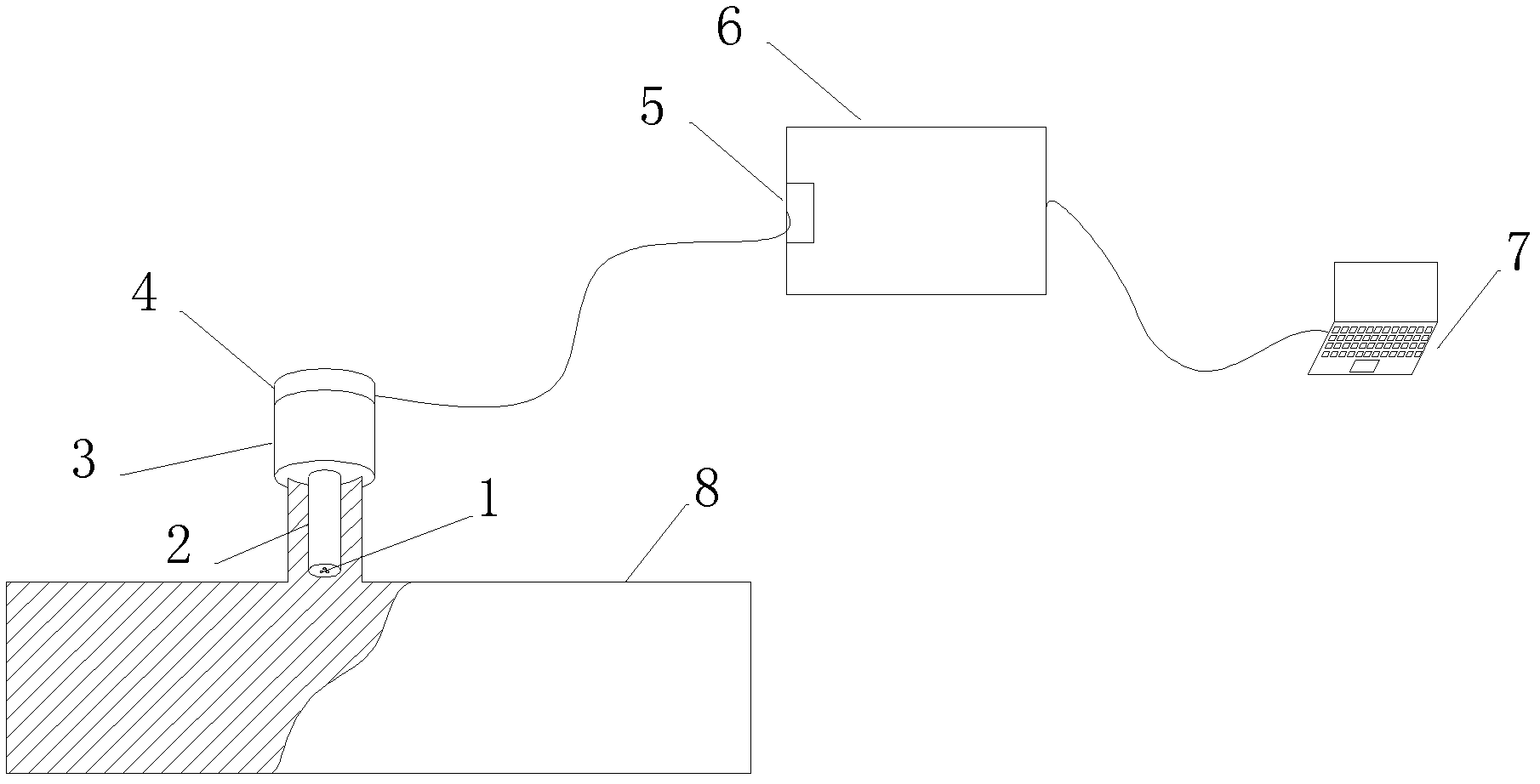

Online monitoring device for corrosion in pipeline

A monitoring device and internal corrosion technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of inability to measure local corrosion characteristics, large errors, and inability to obtain corrosion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The pipeline corrosion online monitoring device is composed of signal acquisition module, signal transmission device, A / D converter, data analysis module, data management module and electronic computer; the electrochemical technology involved in pipeline corrosion online monitoring device includes electrochemical impedance technology, Integration technology of electrochemical noise technology and linear polarization technology. Linear polarization technology applies a small amplitude voltage disturbance to feedback corrosion current information; electrochemical impedance technology applies a small amplitude sinusoidal voltage disturbance to feedback the AC impedance (AC impedance spectroscopy) information of the electrode; electrochemical noise technology does not require external disturbances. Can feedback electrochemical noise information.

[0034] The signal acquisition module includes a three-electrode monitoring probe, a signal generation control unit, a signal buffer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com