Integrated meter tail structure and electric meter including same

A technology of meter tail and electric meter, which is applied in the direction of measuring electrical variables, measuring devices, instruments, etc., can solve the problems of low welding efficiency, unstable welding quality, and inability to integrate operations, so as to avoid repeated welding, stable welding quality, Addresses the effect of burning hands or products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

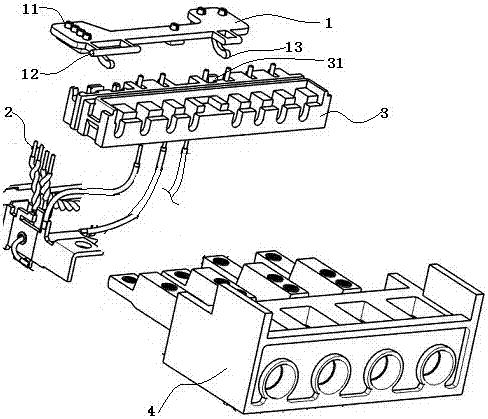

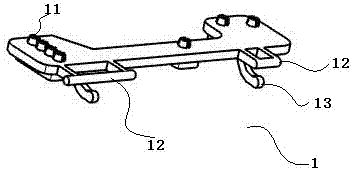

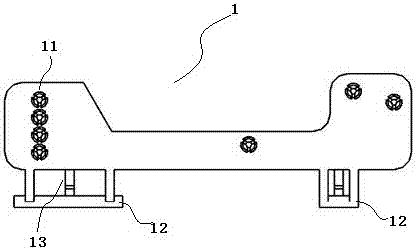

[0031] figure 1 An exploded exploded view of the integrated table tail structure of the present embodiment is given, figure 2 and image 3 The structural schematic diagram and top view of the wire fixing part of this embodiment are respectively given, combined with reference Figure 1~Figure 3 , an integrated tail structure, including a fixed line part 1, a lead wire 2, a first tail part 3 and a second tail part 4, wherein the first tail part 3 is connected and arranged above the second tail part 4, constituting the present The table trailer of the structure.

[0032] As the fixing structure of the lead wire 2, in this embodiment, the wire fixing part 1 is a plate-shaped structure, that is, a wire fixing plate. The wire fixing part 1 includes a wire fixing round hole 11 , a cantilever rod 12 and a buckle 13 . Wherein, the cantilever rod 12 and the buckle 13 are used as the combined parts with the first watch tail part 3, and the cantilever rod 12 and the buckle 13 are loc...

Embodiment 2

[0039] Figure 5 and Figure 6 The exploded exploded view and top view of the electric meter with integrated meter tail structure of this embodiment are respectively given, such as Figure 5 and Figure 6 As mentioned above, in addition to the fixing part 1, the lead wire 2, the first meter tail part 3 and the second meter tail part, the meter also includes a watch case 5, a relay 6, a transformer 7 and a mounting column 8. Wherein, the first watch tail 3 , the second watch tail 4 , the relay 6 and the transformer 7 are fixedly installed in the watch case 5 .

[0040] The external connector of the relay 6 is an in-line terminal 61, which can conveniently realize the connection with components such as a PCB board.

[0041] The relay 6 and the transformer 7 are fixedly connected to the mounting column 8 through the screw 9, and the connection between the two on the mounting column 8 is firm and reliable; the lead wire 2 is respectively drawn from the relay 6 and the transform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com