Novel coating machine

A coating machine, a new type of technology, applied to the surface coating liquid device, coating, surface pretreatment, etc., can solve the problems of affecting production efficiency, increasing production cost, low drying efficiency, etc., to reduce heat supply The effect of reducing consumption and improving drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

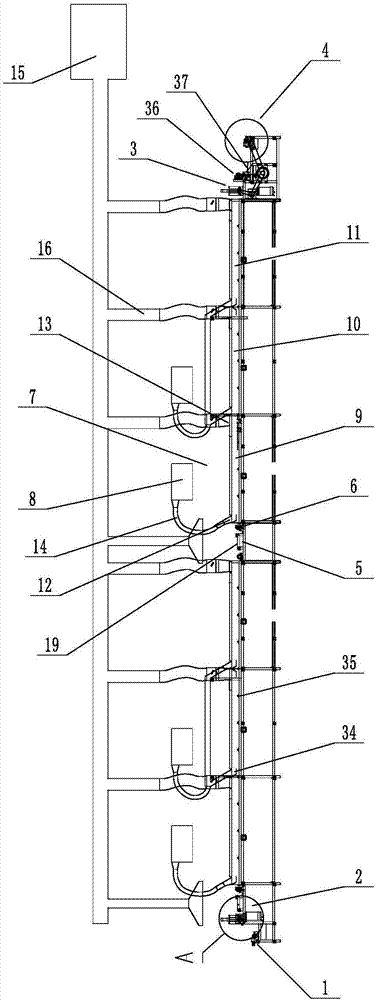

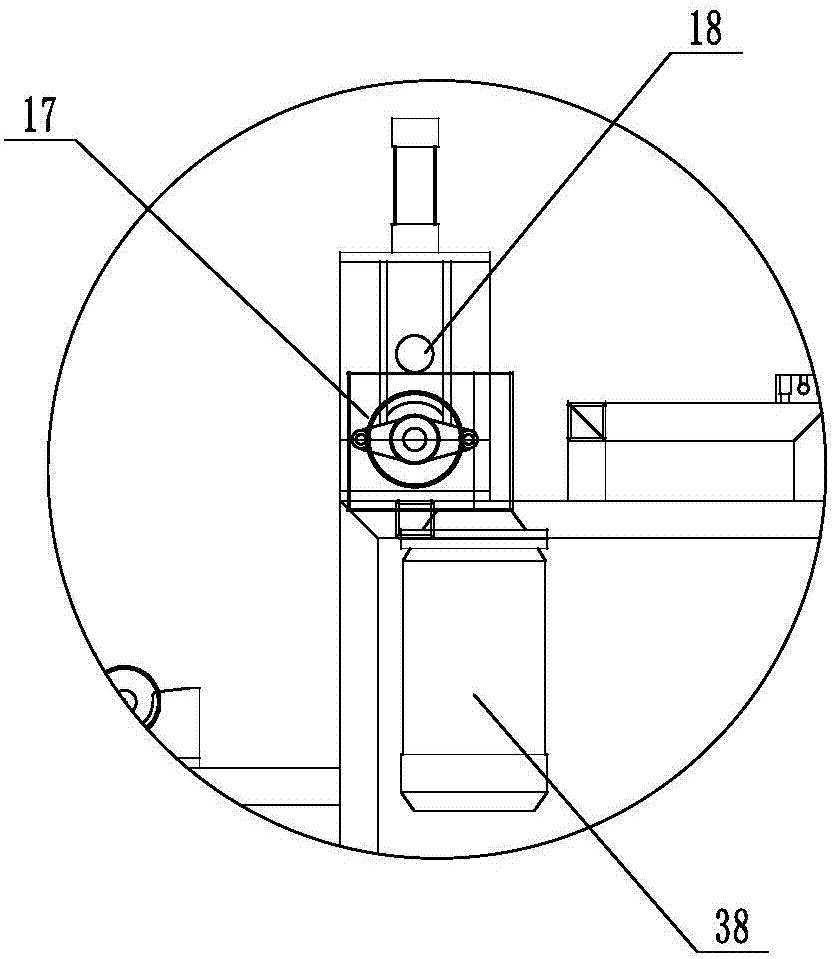

[0021] Such as figure 1 As shown, a new type of coating machine includes an unwinding mechanism 1, a first traction mechanism 2, a coating drying mechanism 7, a second traction mechanism 3 and a winding mechanism 4 arranged in sequence along the conveying direction of the material. There are at least two drying mechanisms 7 along the conveying direction. The coating and drying mechanism 7 includes a gluing mechanism 5, a squeegee mechanism 6 and a drying mechanism 7 arranged in sequence along the conveying direction. The drying mechanism 7 includes a heating device 8 And oven, oven comprises first oven 9, the second oven 10 and the 3rd oven 11 that are arranged successively along conveying direction, first oven 9, second oven 10 and the 3rd oven 11 are all provided with air inlet 12 successively along conveying direction and the air outlet 13, two heating devices 8 are provided, one of which is connected to the air inlet 12 of the first oven 9 through a heating pipeline 14, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com