Novel terahertz carbon fiber composite panel structure,

A technology of terahertz carbon fiber and composite materials, applied in lamination devices, electrical components, lamination, etc., can solve the problems that thermal stability cannot meet the accuracy requirements of terahertz antennas and affect the observation efficiency of high-precision terahertz telescopes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

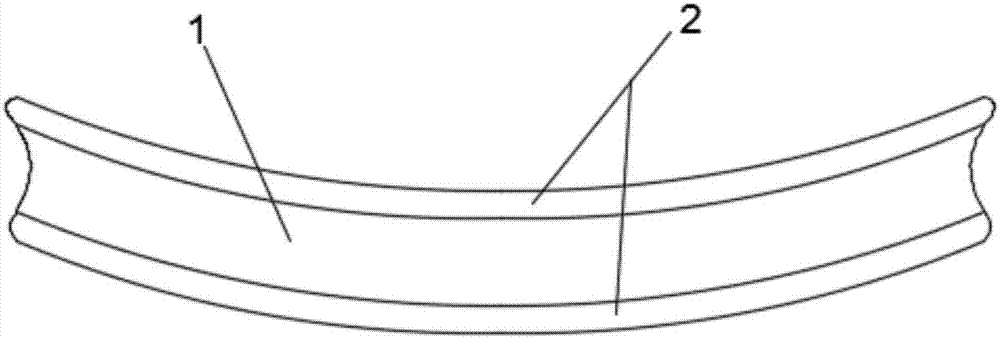

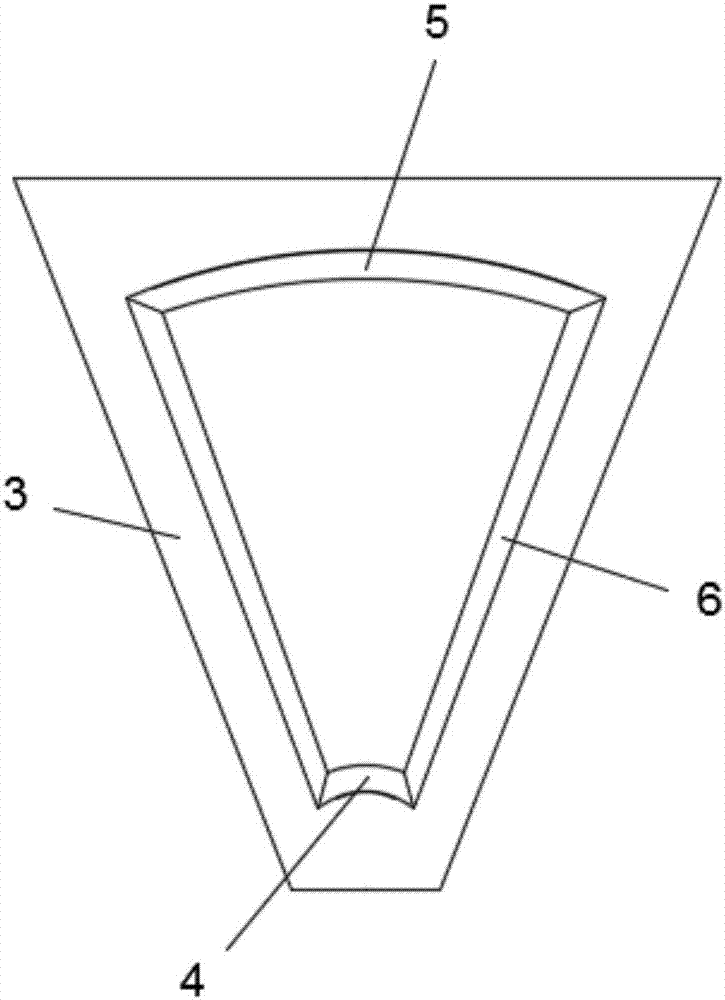

[0013] Such as figure 1 A new type of terahertz carbon fiber composite material panel structure is shown, including a panel body. The panel body is composed of a core material 1 and a skin 2 wrapped on the outer surface of the core material. The upper and lower surfaces of the core material 1 are respectively A layer of skin 2 is connected, the core material 1 is a carbon fiber sandwich structure, the skin 2 is a carbon fiber laminate, and the carbon fiber plywood is connected to the outer surface of the carbon fiber sandwich structure through resin curing and bonding. In extreme environments, the CTE parameter in the normal direction of the carbon fiber structure is at least less than 2×10 -6 / K, so in order to ensure the surface shape accuracy of the panel, this design adopts the panel structure of full carbon material, the core material and the skin are made of carbon fiber material, and the traditional aluminum honeycomb structure is replaced by the carbon fiber structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com