Novel carbon fiber composite material telescope antenna panel structure

A composite material and antenna panel technology, which is applied to antennas, electrical components, layered products, etc., can solve the problems that the thermal stability of the panel structure cannot meet the requirements of antenna accuracy and affect the observation efficiency of high-precision telescopes. The effect of observing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and effect of the present invention clearer and clearer, the following examples are given to further describe the present invention in detail. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

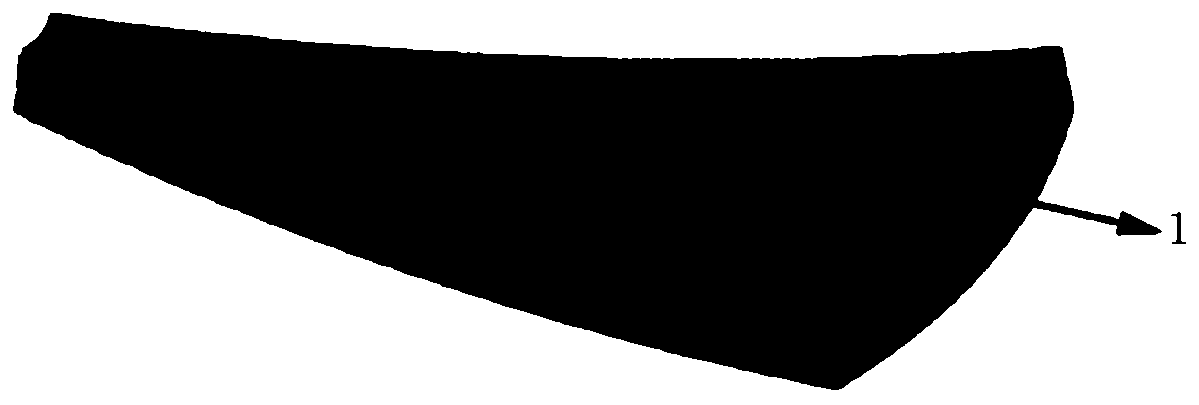

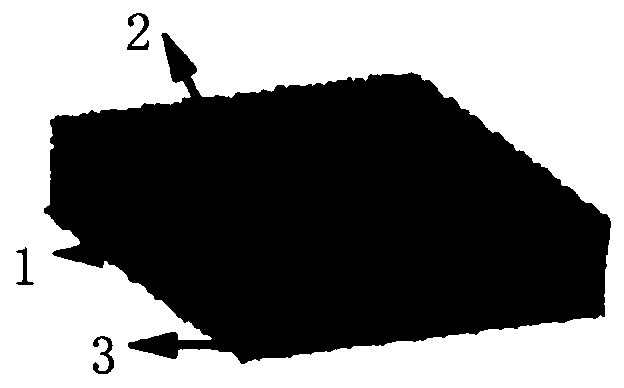

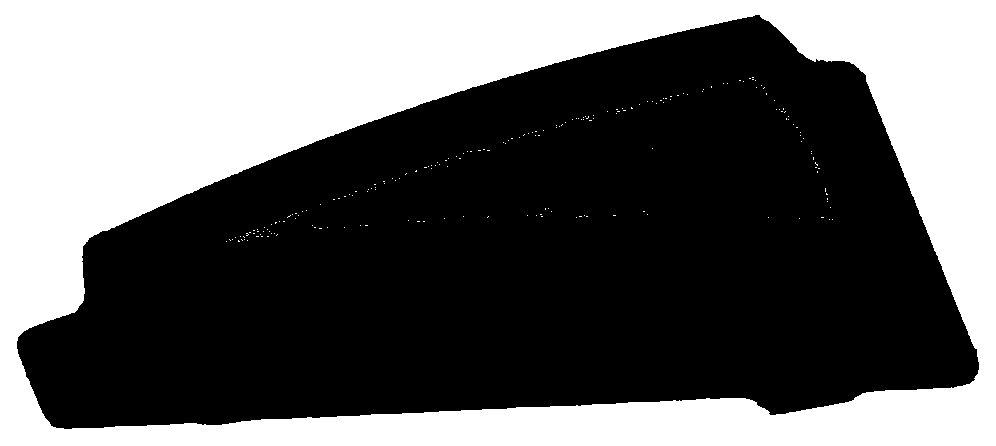

[0015] Such as figure 1 As shown, it is a schematic diagram of a novel carbon fiber composite telescope antenna panel structure of the present invention, including a panel body, which is composed of a core material 1 and a skin wrapped on the outer surface of the core material 1, and the core material 1 is a carbon fiber tube array structure, the skin is a carbon fiber laminate, and the carbon fiber laminate is connected to the outer surface of the carbon fiber sandwich structure through resin curing and bonding. Such as figure 2 The carbon fiber tube array structure shown is a vertical dense arrangement, and the arrangeme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com