Nanofiltration industrial waste water integrated treatment system

A technology for industrial sewage and treatment systems, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of easy clogging and hardening of filter elements and poor filtering effect. To achieve the effect of strengthening the connection stability, improving the filtering effect and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

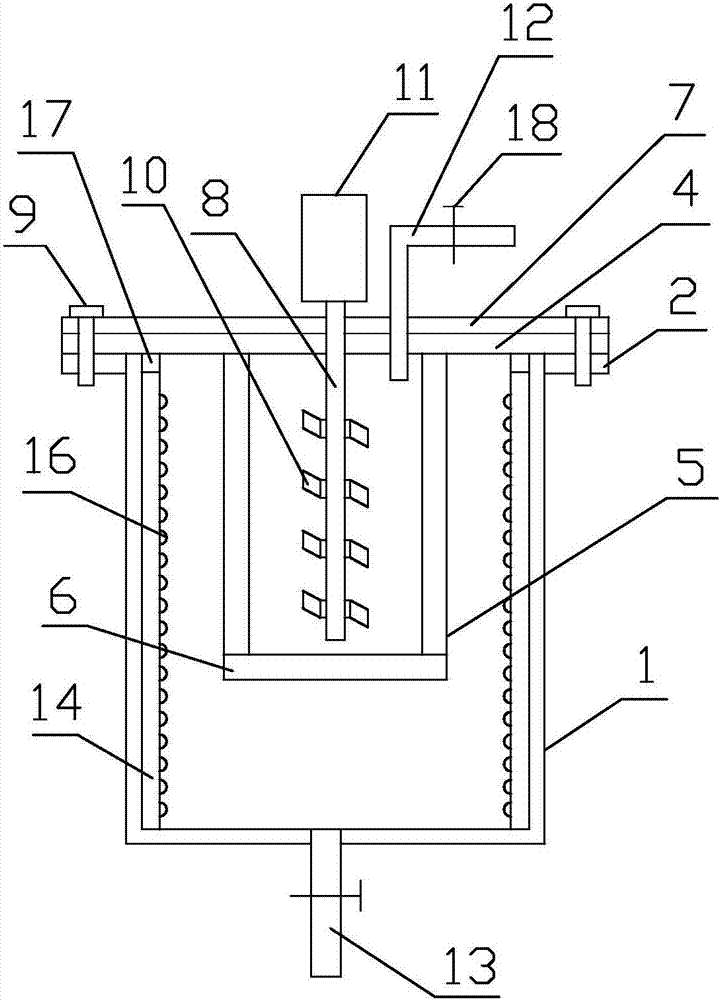

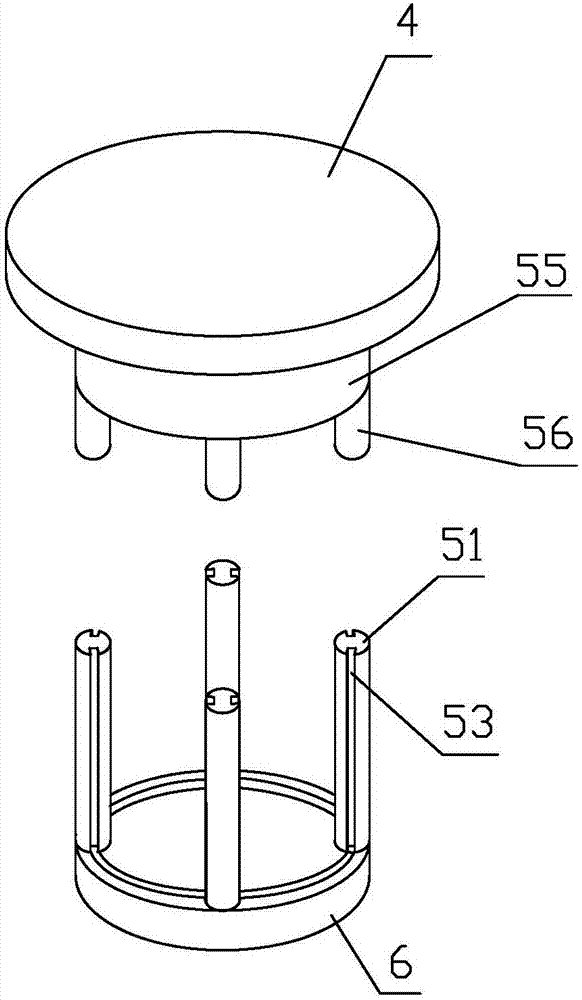

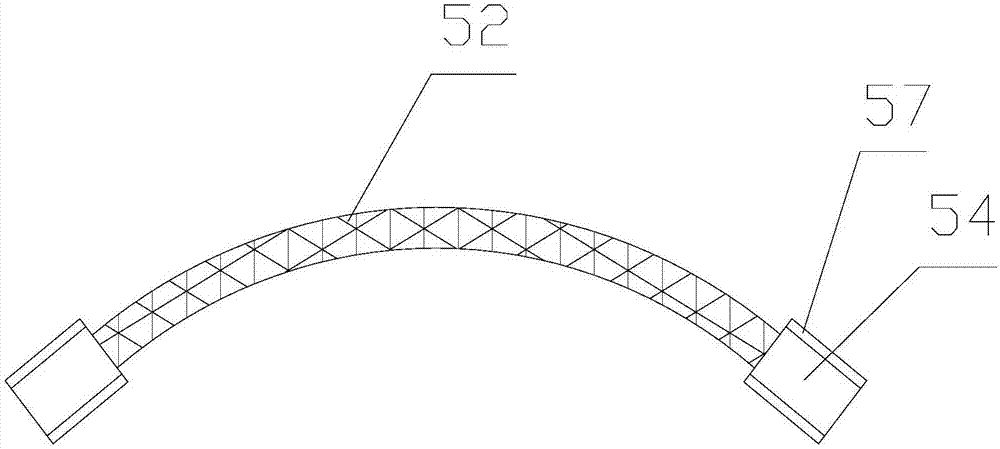

[0028] Such as Figure 1~3 As shown, the nanofiltration industrial sewage integrated treatment system of the present invention includes a vertical cylinder body 1, the bottom end of the cylinder body 1 is closed, and the top end is open. A mounting flange 2 is provided; a filter mechanism and a stirring mechanism are also included, the filter mechanism includes a top plate 4, a filter cartridge 5 and a bottom plate 6, and the filter cartridge 5 is arranged between the top plate 4 and the bottom plate 6; The filter cartridge 5 includes several pillars 51 and several nanofiltration membrane assemblies 52, the nanofiltration membrane assemblies 52 are in an arc-shaped plate structure, one axial end of the pillars 51 is fixed on the installation base plate 6, and the other axial end is detachably connected On the lower surface of the installation top plate 4, and the plurality of pillars 51 are arranged circularly at equal intervals along the circumference of the installation bott...

Embodiment 2

[0030]Further improvement on the basis of Embodiment 1, a mounting sleeve 55 protrudes from the lower surface of the installation top plate 4, and one axial end of the installation sleeve 55 is fixed on the lower surface of the installation top plate 4. The end face provided to the other end is provided with a limit tube 56 adapted to the position and size of the pillar 51 along the circumferential ring. A limiting groove is defined on the end surface of the installation sleeve 55 between the limiting cylinders 56 , and the axial top edge of the nanofiltration membrane module 52 is transition-fitted into the limiting groove. A rubber gasket 57 is provided on the surface of the splint 54 . Between two adjacent pillars 51 on the installation base plate 6 is provided a slot 58 for transitionally fitting the axial bottom edge of the nanofiltration membrane assembly 52 . An auxiliary sleeve 14 is sheathed inside the cylinder body 1 , the outer wall of the auxiliary sleeve 14 is in...

Embodiment 3

[0032] Further improvement on the basis of Example 2, the axial bottom end of the auxiliary sleeve 14 is in contact with the inner bottom wall of the cylinder body 1, and a sealing rubber ring 16 is arranged on the edge of the axial top port along the circumferential ring, and the installation top plate 4 The lower plate surface and the sealing rubber ring 16 are transition-fitted and pressed and fixed. The axial bottom end of the auxiliary sleeve 15 is in contact with the inner bottom wall of the cylinder body 1, and a sealing rubber ring 17 is arranged on the edge of the axial top port along the circumferential ring, and the lower surface of the installation top plate 4 is in transition with the sealing rubber ring 17 Cooperate with pressing and fixing. Both the water inlet pipe 12 and the drain pipe 13 are provided with a water flow control valve 18 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com