Vertical alignment agent, self-alignment liquid crystal mixture and application of self-alignment liquid crystal mixture

A vertical orientation and self-orientation technology, applied in liquid crystal materials, optics, instruments, etc., can solve the problems of product yield loss, panel cost increase, resource waste product cost, etc., to reduce pollution and harm, reduce usage, save The effect of de-process

Inactive Publication Date: 2018-05-08

SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

View PDF7 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This kind of alignment film is mainly divided into friction alignment type PI material and photo alignment type PI material. However, no matter which alignment material has its own disadvantages; first, friction alignment type PI material is easy to cause problems such as dust particles, static electricity residue, brush marks, etc. , thereby reducing the process yield. Although the photo-alignment type PI material can avoid the above problems, due to the limited material properties, the heat resistance and aging resistance are not good, and its ability to anchor LC molecules is also weak, which affects the panel. Second, the PI material itself has the properties of high polarity and high water absorption, so its storage and transportation process are easy to cause deterioration and lead to uneven alignment, and the PI material is expensive, and the film-forming on TFT-LCD The process is also more complicated, resulting in higher panel costs

[0003] In addition, the PI material needs to prepare a PI solution in the film forming process. The PI solution also contains a large amount of N-methylpyrrolidone (NMP) solvent. The process of causing harm to the human body; in addition, due to problems such as alignment layer uniformity, lack of coating, non-stick and foreign matter, it will also cause loss of product yield, resulting in waste of resources and increase in product cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0063] In this embodiment, the vertical alignment agent contains the photoinitiated adsorbent shown in the above formula 4-1; in the self-aligned liquid crystal mixture formed by the vertical alignment agent, the mass percentages of the photoinitiated adsorbent are 0.1% and 0.3% respectively , 1.0%, corresponding to three self-aligned liquid crystal mixtures.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

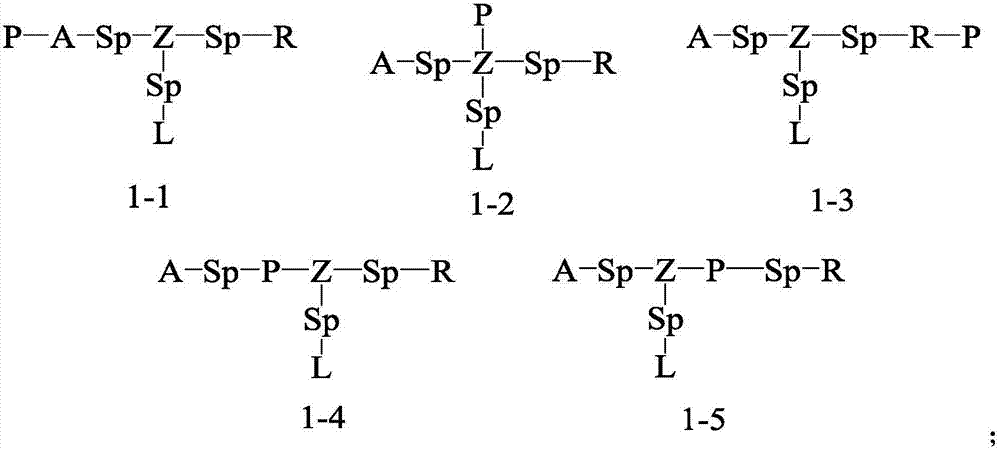

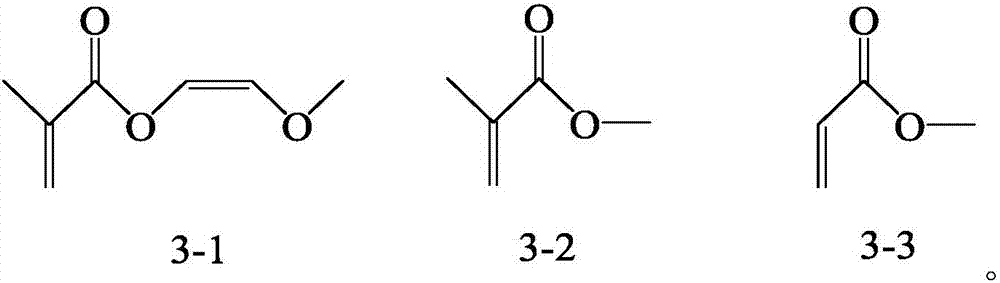

Login to View More Abstract

The invention discloses a vertical alignment agent. The vertical alignment agent comprises uniformly-mixed active monomers RM and a photoinitiated adsorbent, and the photoinitiated adsorbent has a structure shown in any one of formulas 1-1 to 1-5. The invention further discloses a self-alignment liquid crystal mixture comprising the vertical alignment agent. The self-alignment liquid crystal mixture can be used for manufacturing liquid crystal display panels. The invention further discloses a method for manufacturing liquid crystal display panels based on the self-alignment liquid crystal mixture. According to the self-alignment liquid crystal mixture, a self-alignment effect can be achieved on liquid crystal molecules; compared with traditional liquid crystal display panels, the PI stageprocess is omitted, the technology is simplified, the cost is reduced, and pollution and harm are reduced; besides, the light leak problem in the use process can be effectively restrained.

Description

technical field [0001] The technical field of liquid crystal display of the present invention, in particular, relates to a vertical alignment agent, a self-alignment liquid crystal mixture with the vertical alignment agent, and the application of the self-alignment liquid crystal mixture in a liquid crystal display panel. Background technique [0002] On the CF substrate and the TFT substrate in the liquid crystal display (LCD), there is a layer of thin film material, and its main function is to arrange the liquid crystal (LC) molecules between the CF substrate and the TFT substrate in a certain direction, which is generally called alignment. Membrane, which is commonly used polyimide (PI) material. This kind of alignment film is mainly divided into friction alignment type PI material and photo alignment type PI material. However, no matter which alignment material has its own disadvantages; first, friction alignment type PI material is easy to cause problems such as dust pa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09K19/56G02F1/1337

CPCC09K19/56G02F1/1337

Inventor 兰松

Owner SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com