Composite binder for producing oxidized pellets

A technology for oxidizing pellets and binders, applied in the field of smelting, can solve the problems of reducing the compressive strength of high-temperature roasting pellets, high price of organic binders, unstable pellet performance, etc., to improve the falling strength and compressive strength. Strength, improved burst temperature, improved capillary gravitational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] First prepare a new type of composite binder: S1, dissolve 5kg of polyvinyl alcohol in 40kg of hot water at a temperature of 80°C, stir to dissolve, add 0.2kg of sodium borate, and stir to form a mixture; S2, add 0.01kg of lime to the above mixture In the medium, keep warm at 90°C for 1.5h, mix thoroughly, and evaporate to obtain a powdery composite binder.

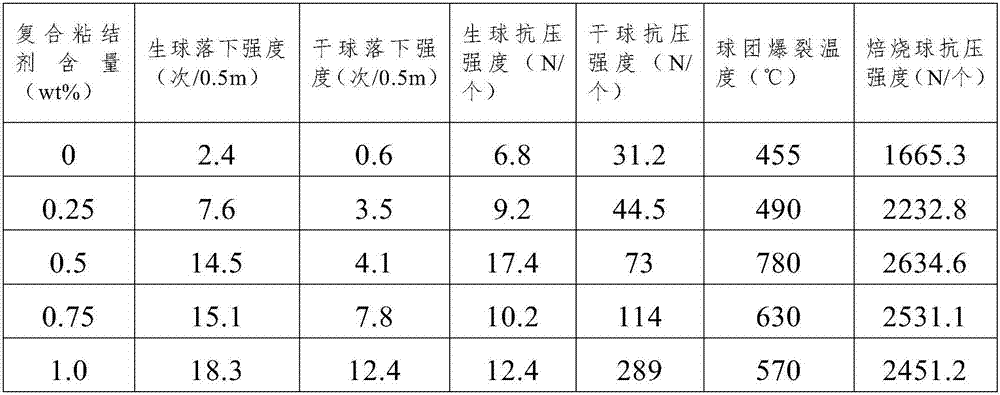

[0024] Take the above-mentioned composite binder with different dosages and 3kg of iron concentrate, add water and stew the material for 30 minutes, and put the stuffed material into the disc pelletizer to produce general oxidized pellets according to the same method as the iron concentrate. The rotation speed is 30r / min, the inclination angle is 45°, and the amount of water added is controlled at about 8% of the total weight of the raw materials. When the number and size of the pellets reach a certain level, spray water while feeding to make the pellets gradually grow larger. When the size of the pellets reaches a...

Embodiment 2

[0030] First prepare a new type of composite binder: S1, dissolve 7kg of polyvinyl alcohol in 55kg of hot water at a temperature of 80°C, stir magnetically for 10 minutes to dissolve, add 0.4kg of potassium borate, and stir to form a mixture; S2, add 1kg of lime to the above mixture In the medium, keep warm at 100°C for 1 hour, mix thoroughly, and evaporate to obtain a powdery composite binder.

[0031] Take 0.05 kg of the above-prepared binder, add it to 9.95 kg of iron ore concentrate, and prepare oxidized pellets as in Example 1. The prepared pellets will be tested, and the compressive strength of green pellets can reach 40N, and the compressive strength of roasted pellets can reach 40N. The strength can reach 2708N.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com