Preparation method of magnesium-aluminum alloy

A technology of magnesium-aluminum alloy and metal titanium is applied in the field of preparation of magnesium-aluminum alloy, which can solve the problems of easy fracture, wear, high labor intensity of workers, low production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The high-purity magnesium 20%, the metal titanium 3%, the metal manganese 5%, the metal copper 8%, the metal iron 2%, and the high-purity aluminum 57% are batched according to the mass percentage, and smelted at 800 ℃ in a nitrogen atmosphere, keeping the temperature in the smelting furnace. The pressure is 800Pa; after smelting for 2h, keep the temperature at 600℃, add 5% of silicon nitride according to the mass percentage, stir to make it evenly dispersed, and then smelt for 1h, keeping the pressure in the smelting furnace at 600Pa; Pouring to obtain a magnesium-aluminum alloy ingot, and annealing and cooling the magnesium-aluminum alloy ingot to obtain a magnesium-aluminum alloy material.

Embodiment 2

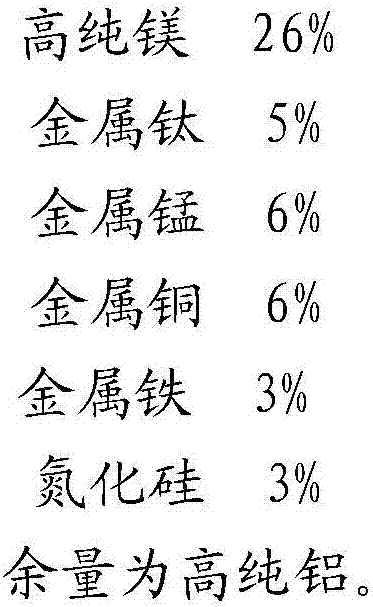

[0033] The high-purity magnesium 26%, the metal titanium 5%, the metal manganese 6%, the metal copper 6%, the metal iron 3%, and the high-purity aluminum 51% are batched according to the mass percentage, and smelted at 900 ℃ under a nitrogen atmosphere, keeping the temperature in the smelting furnace. The pressure is 900Pa; after smelting for 2h, keep the temperature at 600℃, add 3% of silicon nitride according to the mass percentage, stir to make it evenly dispersed, and then smelt for 1h, keeping the pressure in the smelting furnace at 500Pa; Pouring to obtain a magnesium-aluminum alloy ingot, and annealing and cooling the magnesium-aluminum alloy ingot to obtain a magnesium-aluminum alloy material.

Embodiment 3

[0035] The high-purity magnesium 30%, the metal titanium 2%, the metal manganese 8%, the metal copper 4%, the metal iron 2%, and the high-purity aluminum 48% are batched according to the mass percentage, and smelted at 800 ℃ in a nitrogen atmosphere, keeping the temperature in the smelting furnace. The pressure is 1000Pa; after smelting for 2h, keep the temperature at 600℃, add 6% of silicon nitride according to the mass percentage, stir to make it evenly dispersed, and then smelt for 1h, keeping the pressure in the melting furnace at 800Pa; Pouring to obtain a magnesium-aluminum alloy ingot, and annealing and cooling the magnesium-aluminum alloy ingot to obtain a magnesium-aluminum alloy material.

[0036] Through experimental verification, in the above-mentioned embodiments, the magnesium-aluminum alloy material obtained in Example 2 has relatively better performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com