A method for preparing a rotating target with an adaptive buffer layer

A buffer layer and self-adaptive technology, applied in coating, metal material coating process, vacuum evaporation plating, etc., can solve problems such as target cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

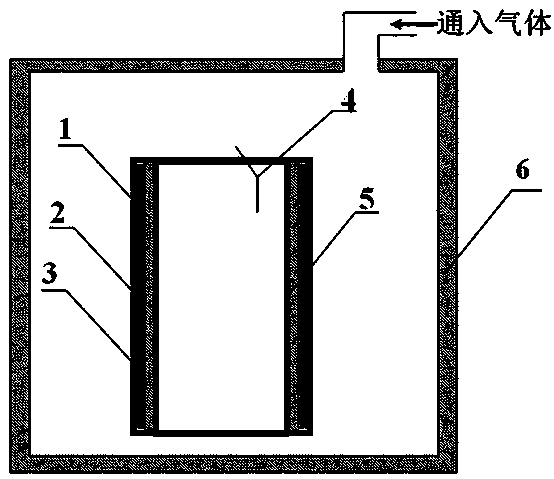

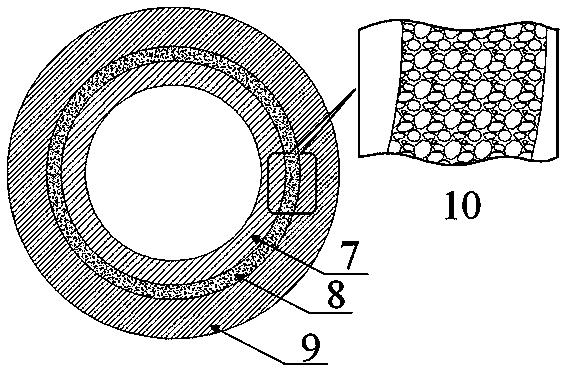

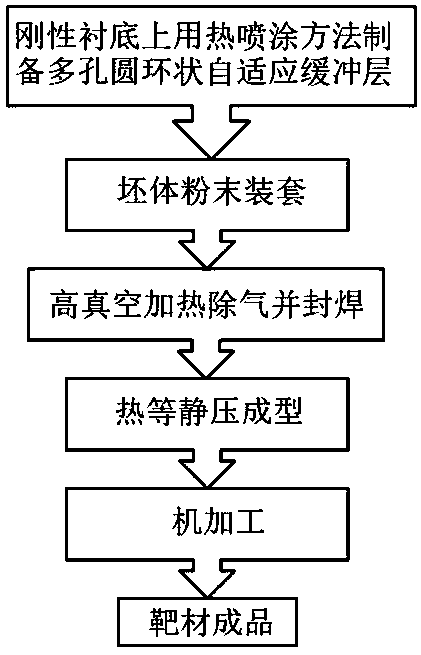

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Pure silicon target

[0039] The lining pipe is made of 304 stainless steel. At the same time, the buffer layer material powder is selected, and the thermal expansion coefficient of the material selected for the buffer layer is between 304 stainless steel and the silicon target body, and does not affect heat conduction. Then the porous self-adaptive ring-shaped buffer layer is prepared by thermal spraying, and the thickness of the buffer layer is guaranteed to be 1 / 5-1 / 7 of the thickness of the silicon target body. The outer casing is made of ordinary carbon steel sheet, welded and assembled, and inspected by ultrasonic flaw detection and penetrant flaw detection before loading. Use silicon powder with an average particle size of 50-75μm. The purity of the silicon powder is not less than 99.9%, and the oxygen content must be less than 250PPm. Calculate the required silicon powder weight according to the thickness and length of the prepared rotating target. ...

Embodiment 2

[0040] Example 2: Si-aluminum alloy target

[0041] The lining pipe is made of 304 stainless steel. At the same time, the buffer layer material powder is selected, and the thermal expansion coefficient of the material selected for the buffer layer is between 304 stainless steel and the silicon-aluminum alloy target body, and does not affect heat conduction. Then prepare the porous self-adaptive ring-shaped buffer layer by thermal spraying, and ensure that the thickness of the buffer layer is 1 / 5-1 / 7 of the thickness of the silicon-aluminum alloy target blank. The outer casing is made of ordinary carbon steel sheet, welded and assembled, and inspected by ultrasonic flaw detection and penetrant flaw detection before loading. Use silicon powder with an average particle size of 50-75μm, the purity of the silicon powder is not less than 99.9%, and the oxygen content must be lower than 250PPm, and the aluminum powder with an average particle size of 20μm, the purity of the aluminum...

Embodiment 3

[0042] Example 3: Niobium oxide target

[0043] The lining pipe is made of 304 stainless steel. At the same time, the buffer layer material powder is selected, and the thermal expansion coefficient of the material selected for the buffer layer is between 304 stainless steel and the niobium oxide target body, and does not affect heat conduction. Then the porous self-adaptive annular buffer layer is prepared by thermal spraying, and the thickness of the buffer layer is guaranteed to be 1 / 5-1 / 7 of the thickness of the niobium oxide target blank. The outer cover is made of ordinary carbon steel sheet. After welding and assembly, before loading, it is inspected by ultrasonic flaw detection and penetrant flaw detection. Use niobium oxide powder with an average particle size of 80-100μm, usually the purity of niobium oxide powder is 3N5 (99.95%) must be guaranteed not less than 99.95%, the oxygen content is about 300PPm, you can add a small amount according to niobium oxide: tantalu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com